China best selling VFD Frequency Drive 3 phase 220V 380V

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 pc

- Supply Capability:

- 100000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specifications

1.220V Single Phase Variable Frequency Drive 2.2KW

2.Advanced control technology

3.Easy to operate

220V Single Phase Variable Frequency Drive 2.2KW

General

CNBM frequency inverter is a high-quality, multi-function,

low-noise variable frequency drive which is designed, developed and manufactured according to international standards.

It can meet different needs of industrial conditions.

The inverter applies advanced control technology of space voltage vector PWM, with functions of constant voltage control, power-off restart, dead zone compensation, automatic torque compensation, online modification parameter, high-speed impulse input, simple PLC and traverse.

Product Name:CMAX-VCG15/P18.5T3 ~ CMAX-VCG18.5/P22T3

Application

Textile: coarse spinner, spinning frame, wrap-knitting machine, loom, knitting machine, silk-spinning machine, etc.

Plastic: extruder, hauling machine, decorating machine, etc.

Pharmacy: mixer, roaster, etc.

Woodworking: engraving machine, sander, veneer peeling lathe, etc.

Papermaking: single type papermaking machine, etc.

Machine tool: non-core grinding machine, optical lens grinding machine, cutting mill, etc.

Printing: cloth-washing machine, dye vat, etc.

Cement: feeder, air blower, rotary furnace, mixer, crusher, etc

Fan and pump: kinds of fans, blowers and pumps

Specification

Item | Specification | |

Input | Input voltage | 220/380V±15% |

Input frequency | 47~63Hz | |

Output | Output voltage | 0~input voltage |

Output frequency | 0~600Hz | |

Peripheral interface characteristics | Programmable digital input | 4 switch input, 1 high-speed impulse input |

Programmable analog input | AI1: 0~10V input AI2: 0~10V input or 0~20mA input, | |

Programmable open collector output | 2 Output (3.7kW and above: 1 Open collector output) | |

Relay Output | 1 Output (3.7kW and above: 2 Relay output) | |

Analog output | 2 Output, one is 0~10V, another is 0~20mA or 0~10V | |

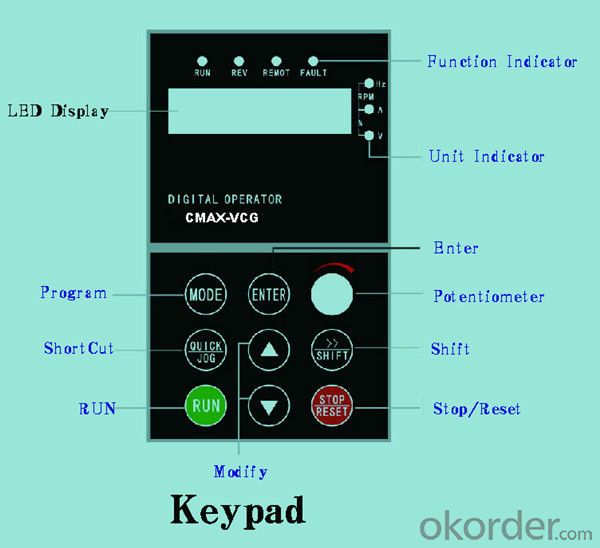

Keypad | Display:5-digit 8-section LED (Red), 2 indicators; parameter setting: 8 keys (including multi-function hot key ), 1 potentiometer | |

Technical performance characteristics | Control mode | All digital space voltage vector SVPWM algorism |

Overload capacity | G purpose: 150% rated current 60s P purpose: 120% rated current 60s | |

Speed ratio | 1: 100 | |

Carrier frequency | 1.0~10.0kHz | |

Torque compensation | Linear, multi-point, 1.3th power, 1.7th power, 2.0th power reduced torque; Compensation voltage range: automatic compensation and manual compensation 0.1~10% | |

Automatic voltage adjustment | It can automatically maintain output voltage constant when grid voltage fluctuates. | |

Automatic current adjustment | When the current is over current limit, under clocking automatically limits output current. | |

Function characteristics | Frequency setting mode | Keypad digital analog input, keypad potentiometer, impulse frequency, communication, multi-step speed and simple PLC, PID setting and so on, switch-over of setting modes. |

Simple PLC, multi-step speed control | 16-step speed control | |

Special function | Traverse control, length control, time control | |

QUICK/JOG key | User-defined multi-function hot key | |

Protection function | Over-current, Over voltage, under-voltage, over-heat, phase failure, over-load and motor over-load | |

Working condition | Installation site | Indoor, altitude of less than 1km, dust free, non-corrosive gases, no direct sunlight |

Application environment | -10°C~+40°C, 20~90%RH (no dew) | |

Vibration | Less than 0.5g | |

Storage temperature | -25°C~+65°C | |

Installation type | Wall-mounted type, floor cabinet type | |

Cooling mode | Air-forced cooling | |

- Q: What is the working principle of elevator frequency converter?

- Yaskawa 616G5 transducer current vector in the world as one of the inverter control, speed range to reach 1:1000, the control accuracy of 0.02%, with the starting torque at zero speed can reach 150% characteristics. In particular, Yaskawa unique all fields, automatic torque boost function can get comfort and good stability in the lift drag in.G5 can accept controllers such as multi speed frequency command PLC or analog voltage and current instruction; can adapt to all kinds of motor vector control and self-learning to obtain good characteristics; low speed starting smoothly excellent reliability and high cost of hardware.

- Q: How does the PLC process the inverter output signal?

- Depends on analog or switch volume, if it is analog, you can use analog input module, if it is the amount of switching, with ordinary IO on it

- Q: How to deal with the fault Yaskawa inverter GF

- Inverter display "GF" fault information for ground fault (i.e. the output current exceeds the rated current of the inverter 50%), a power module is reported for G5 damage, may also be a driving circuit, running the report "GF" (the external load is a good case), G5 is PC929 damage. With current detection circuit,

- Q: The frequency converter works with sharp noises. What's the process of converting electrical energy into mechanical energy?. The mechanism of sound making. Thank you

- Frequency converter (Variable-frequency, Drive, VFD) is the application of frequency conversion technology and microelectronics technology, by changing the power supply frequency of the motor to control AC motor power control equipment.

- Q: I would like to ask, the inverter in use in the grid is very high?

- In the process of using frequency converter, the demand for voltage fluctuation of power grid is not high, generally single-phase is allowed to + 20% fluctuations, three-phase is allowed to + 15% fluctuations.Frequency converter is the application of frequency conversion technology and micro electronics technology, by changing the power supply frequency of the motor to control AC motor power control equipment. The frequency converter is mainly composed of rectifier (AC DC converter), filter, inverter (DC AC converter), brake unit, drive unit, detection unit, micro processing unit and so on. Inverter by internal IGBT drive voltage and frequency off to adjust the output power, the power supply voltage required to provide according to the actual needs of the motor, so as to achieve the purpose of speed, energy saving, in addition, there are a lot of protection drive, such as over-current, over-voltage, overload protection and so on. With the continuous improvement of the degree of industrial automation, inverter has also been widely used.

- Q: What is the over-current of the inverter?

- When the load is not stable, recommend the use of DTC DTC control mode, because the speed is very fast, the actual torque and flux generated every 25 microseconds a set of precise value after comparator and output torque of the motor flux comparator, optimized pulse selector switch inverter decided to best position, such a system over current. In addition, the speed loop adaptive (AUTOTUNE) will automatically adjust the PID parameters, so that the inverter output motor current is stable.

- Q: What's the difference between universal inverter and fan pump converter?

- Constant power load:The torque required by machine spindles and rolling mills, paper machines, and plastic film production lines is generally inversely proportional to the rotational speed, which is called constant power load. The constant power nature of the load should be in terms of a range of speed variations. When the speed is very low, the mechanical strength limit, TL can not be infinitely increased, at low speed into a constant torque nature. The constant power area and the constant torque area of the load have a great influence on the choice of transmission scheme. When the motor is in constant flux speed regulation, the maximum allowable output torque is constant, which belongs to constant torque speed regulation. While in the speed regulation of magnetic flux weakening, the maximum allowable output torque is inversely proportional to the speed, which belongs to constant power speed regulation. If the constant torque of the motor and the range of constant power speed are consistent with the constant torque of the load and the range of constant power, the capacity of the motor and the capacity of the converter are all the smallest, which is called "matching".

- Q: Which brand of converter is better?

- Shanghai Leinuoer recommended! Soft starter and frequency converter products Shanghai Leinuoer company, national key products, Shanghai famous trademark! People's Insurance Company of China quality assurance! Shanghai World Expo Shanghai reyrolle company supporting the project, the Beijing Olympic Games project,

- Q: What do you mean by the capacity of the inverter and the capacity of the motor?

- That's not the case at all"Capacity" and "power" are essentially different. Usually we say that a large transformer capacity is how much KVA, but not to say how much KW, because the two are not the same thing

- Q: Electronic governor for single-phase motor speed control, frequency converter for three-phase motor speed regulation, what are their differences in speed control effect? How does the frequency converter adjust speed? Can you give me an example?

- Is the original power inverter direct input three-phase asynchronous motor inverter in inverter internal access first, through PWM electronic converter technology will AC rectifier, inverter, a controllable frequency alternating current at the input to the motor, the motor operation can be controlled by V/F, output torque control and vector control control frequency, change the loop current, realize energy-saving operation, especially the energy saving effect is obvious in the motor at light load is a kind of energy-saving products, has been widely spread and applied.

Send your message to us

China best selling VFD Frequency Drive 3 phase 220V 380V

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 pc

- Supply Capability:

- 100000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords