Aluminum Cladding Profiles - CC Aluminum Plate for Coated Decoration

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 6 m.t.

- Supply Capability:

- 3400 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

1) Alloy | 1050, 1060,1100, 3003 3004 3105 3005 5005 5052 etc |

2) Temper | O/H12/H14/H1/H18/H32/H34/H36/H38//H111/H112/H116/H321/T6/T651/T3/T351 etc |

3) Thickness | 0.1mm to 6mm |

4) Width | 20mm to 3300mm |

5) Coil weight | 100kgs to 6 tons depends on actual requirement |

6) Core material | Aluminum alloy |

7) Coil Inner diameter | 76mm, 152mm,or as required |

2. Application of Aluminum

(1).Interior: wall cladding, ceilings, bathrooms, kitchens and balconies, shutters, doors...

(2).Exterior: wall cladding, facades, roofing, canopies, tunnels,column covers , renovations...

(3).Advertisement: display platforms, signboards, fascia, shop fronts...

3. Feature of Aluminum

*Such coil is specially designed to replace aluminum ingot, due to the high export tax of aluminum ingot, the coil has better price than ingot.

*This type of coil can fit customer's remelting furnace just like ingot, no need to make any change to the production line that was previously used for ingot. The standard coil size and weight is very suitable for the feed gate of furnace.

*This type of coil causes less material wastage than ingot when remelted.

*Our coil is made directly from ore, no need to go though the ingot making process, quality is much better than other suppliers who use ingot scrap to make coil.

Be free from Oil Stain, Dent, Inclusion, Scratches, Stain, Oxide Dicoloration, Breaks, Corrosion, Roll Marks, Dirt Streaks and other defect which will interfere with use

4. Certificate:

SGS and ROHS(if client request, paid by client), MTC(plant provided), Certificate of Origin(FORM A, FORM E, CO), Bureau Veritas and SGS (if client request, paid by client), CIQS certificate

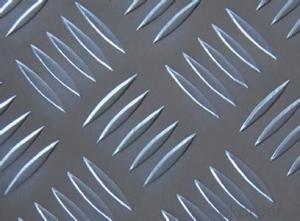

5. Image of Aluminum

6. Our Service

1. Reply your enquiry in 24 working hours. |

2. OEM, buyer design, buyer label services provided. |

3. Exclusive and unique solution can be provide to our customer by our well traned and professional engineers and staffs. |

4. We can provide free sample for your check |

5. We have the certification of ISO 9001 |

6. Timely delivery |

7. Special discount and protection of sales area provided to our distributor. |

8. Good after-sale service. |

7. FAQ

Q: What is the produce prase? |

A: Normally it would be 40days after received your deposit. |

Q: Can you provide free samples? |

A: Yes, free samples will be sent to you on freight at destination. |

Q: Can I get your latest catalogue? |

A: Yes, it will be sent to you in no time. |

Q: What is the MOQ? |

A: 3 tons |

Q: What are your payment terms? |

A: We accept L/C, D/A, D/P, T/T, West Union,etc. |

- Q: What are the advantages of using aluminum profiles in the renewable energy sector?

- There are several advantages of using aluminum profiles in the renewable energy sector. Firstly, aluminum profiles are lightweight yet strong, making them ideal for constructing solar panel frames, wind turbine components, and other renewable energy infrastructure. Their strength-to-weight ratio allows for easy transportation and installation, reducing costs and improving efficiency. Secondly, aluminum profiles are highly corrosion-resistant, making them suitable for outdoor applications in harsh environments. This durability ensures that the renewable energy infrastructure remains stable and functional for extended periods, even in coastal or corrosive environments. Additionally, aluminum profiles offer excellent thermal conductivity, which is crucial for effective heat dissipation in renewable energy systems. This property allows for efficient cooling of solar panels, wind turbine generators, and other components, thus enhancing their performance and lifespan. Furthermore, aluminum is a sustainable material that can be easily recycled. As the renewable energy sector focuses on promoting sustainability, using aluminum profiles aligns with the industry's goals. Aluminum can be recycled repeatedly without losing its properties, reducing the demand for primary aluminum production and minimizing the carbon footprint of renewable energy projects. Lastly, aluminum profiles offer design flexibility and versatility. They can be easily customized and fabricated into various shapes and sizes, allowing for efficient integration into different renewable energy applications. This adaptability enables engineers and designers to optimize the use of aluminum profiles, resulting in improved energy efficiency and overall system performance. In conclusion, the advantages of using aluminum profiles in the renewable energy sector include their lightweight yet strong nature, corrosion resistance, thermal conductivity, sustainability, and design flexibility. By incorporating aluminum profiles into renewable energy infrastructure, we can enhance the efficiency, durability, and environmental sustainability of the sector.

- Q: What are the different types of surface protection for aluminum profiles?

- There are several different types of surface protection options available for aluminum profiles. These options are designed to enhance the durability and aesthetics of the aluminum profiles and provide protection against various environmental factors. 1. Anodizing: Anodizing is one of the most common methods of surface protection for aluminum profiles. It involves creating a protective oxide layer on the surface of the aluminum through an electrochemical process. Anodizing provides excellent corrosion resistance and can be done in various colors. 2. Powder Coating: Powder coating involves applying a dry powder to the surface of the aluminum profiles, which is then cured under heat to form a protective layer. Powder coating offers a wide range of color options, excellent durability, and resistance to scratching, chipping, and fading. 3. Paint: Painting is another option for surface protection of aluminum profiles. It involves applying a liquid paint coating to the surface, which provides both protection and aesthetic enhancement. Paint can be customized in terms of color, texture, and finish, but it may not be as durable as other options. 4. Clear Coating: Clear coating is a transparent protective layer that can be applied to aluminum profiles. It provides a glossy finish while preserving the natural appearance of the aluminum. Clear coating offers protection against corrosion, UV radiation, and other environmental factors. 5. Cladding: Cladding involves covering the aluminum profiles with another material, such as stainless steel or composite panels. This provides additional protection against corrosion and wear, while also adding aesthetic appeal and design versatility. 6. Film/Protective Tape: Applying a temporary film or protective tape to the surface of aluminum profiles can provide short-term protection during transportation, installation, or construction. These films or tapes can be easily removed after use, leaving the aluminum profile intact. Each of these surface protection options has its own advantages and disadvantages, and the choice depends on the specific requirements of the application, desired aesthetics, budget, and expected environmental conditions.

- Q: Can aluminum profiles be used in the production of audiovisual equipment?

- Yes, aluminum profiles can be used in the production of audiovisual equipment. Aluminum is a versatile and widely used material in various industries, including the audiovisual sector. Aluminum profiles can be used to construct frameworks, enclosures, and mounting systems for audiovisual equipment such as speakers, projectors, and television screens. The lightweight nature of aluminum makes it easy to handle and transport, while its high strength-to-weight ratio ensures durability and stability. Additionally, aluminum is corrosion-resistant, which is crucial for equipment that may be exposed to moisture or humidity. Aluminum profiles can also be easily customized and fabricated to meet specific design requirements, allowing for flexibility in the production of audiovisual equipment. Overall, the use of aluminum profiles in the production of audiovisual equipment offers numerous advantages in terms of strength, weight, corrosion resistance, and design possibilities.

- Q: Is it possible to utilize aluminum profiles as part of the exterior cladding systems for commercial buildings?

- <p>Yes, aluminum profiles are commonly used for exterior cladding systems in commercial buildings. They offer several advantages such as durability, resistance to weather and corrosion, low maintenance, and a modern aesthetic. Aluminum's lightweight nature and strength make it an ideal material for cladding, and it can be easily shaped and joined to create a variety of designs. Additionally, aluminum profiles can be coated or anodized to provide color and further protection against the elements.</p>

- Q: Can aluminum profiles be used in the construction of exhibition stands?

- Yes, aluminum profiles can be used in the construction of exhibition stands. Aluminum profiles are lightweight, durable, and easy to work with, making them a popular choice for building exhibition stands. They can be easily cut, shaped, and assembled to create custom designs that meet the specific requirements of the exhibition. Additionally, aluminum profiles can be powder-coated or anodized to provide a wide range of finishes, enhancing the aesthetic appeal of the exhibition stand. Furthermore, aluminum is resistant to corrosion and can withstand various weather conditions, ensuring the longevity of the exhibition stand. Overall, using aluminum profiles in the construction of exhibition stands offers flexibility, durability, and a sleek appearance.

- Q: Can aluminum profiles be used for safety barriers or guardrails?

- Yes, aluminum profiles can be used for safety barriers or guardrails. Aluminum is a lightweight yet strong material that has excellent durability and corrosion resistance. These properties make it suitable for various applications, including safety barriers and guardrails. Aluminum profiles can be easily fabricated into different shapes and sizes, allowing for customization to meet specific requirements. They can be used in various settings such as industrial facilities, construction sites, roads, and walkways. Aluminum profiles can be designed to withstand impact and provide protection against falls or accidents. Additionally, aluminum profiles offer aesthetic appeal as they can be powder-coated in different colors to enhance visibility or blend with the surroundings. They are also low maintenance, requiring minimal upkeep compared to other materials. Aluminum profiles for safety barriers or guardrails are a cost-effective solution due to their long lifespan and recyclability. They are resistant to weather conditions, including UV rays and extreme temperatures, which ensures their performance and longevity. In summary, aluminum profiles are a suitable choice for safety barriers or guardrails due to their strength, durability, customization options, aesthetic appeal, low maintenance, and cost-effectiveness.

- Q: What are the fire-resistant properties of aluminum profiles?

- Aluminum profiles offer a range of fire-resistant qualities that render them suitable for a variety of uses. Firstly, aluminum boasts a remarkably high melting point of around 660 degrees Celsius (1220 degrees Fahrenheit), enabling it to endure extreme temperatures without succumbing to melting or compromising its structural integrity. Furthermore, aluminum possesses a low ignition point, necessitating a higher temperature than other metals to ignite. This attribute reduces the likelihood of aluminum catching fire when exposed to heat or flames. In the event of a fire, aluminum profiles generate a protective layer of aluminum oxide on their surface owing to their innate oxide layer. This layer acts as a barrier, impeding the propagation of flames and hindering the combustion process. Moreover, the aluminum oxide layer exhibits exceptional heat resistance, thereby providing supplementary defense against elevated temperatures. Additionally, aluminum profiles are non-combustible, meaning they do not contribute to the expansion of a fire. This characteristic assumes critical importance in ensuring fire safety by containing the fire within a specific zone and averting rapid spreading. Taken together, the fire-resistant attributes of aluminum profiles, encompassing their high melting point, low ignition point, the formation of a protective oxide layer, and non-combustibility, establish them as a dependable choice for a wide range of applications where fire safety is a paramount concern.

- Q: Why should aluminum surface treatment process?

- The hard oxide film formed after the surface oxidation treatment prevents the internal aluminum from being oxidized and prolongs the service life of the aluminum profile.

- Q: What is the nitriding process of aluminum extrusion die?

- Nitriding process:The main process parameters of gas nitrocarburizing are nitriding temperature, nitriding time, and nitriding atmosphere.The gas soft nitriding temperature is usually 560-570 DEG C, because the nitrided layer has the highest hardness at this temperature. The nitriding time is usually 3-4 hours, because the hardness of the compound layer reaches the maximum at 2-3 hours after penetration, while the depth of the nitrided layer increases slowly with time. The nitriding atmosphere is determined by the rate of ammonia decomposition and the rate of dripping of the carbonaceous penetrant.

- Q: This question asks about the various methods for connecting aluminum profiles using fasteners.

- <p>There are several ways to join aluminum profiles together using fasteners: 1. Bolts and Nuts: Commonly used for strong and removable connections. 2. Rivets: Provide a permanent connection, suitable for high-stress applications. 3. Screws: Offer a secure and adjustable connection, often used in furniture and construction. 4. Pins: Used for alignment and positioning, often in lighter applications. 5. Adhesives: Can be used for a more aesthetically pleasing joint, though not as strong as mechanical fasteners. 6. Welding: Although not a fastener method, it is a common way to join aluminum profiles for a permanent and strong bond. Each method has its advantages and is chosen based on the specific requirements of the application, such as strength, permanence, and ease of assembly.</p>

Send your message to us

Aluminum Cladding Profiles - CC Aluminum Plate for Coated Decoration

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 6 m.t.

- Supply Capability:

- 3400 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords