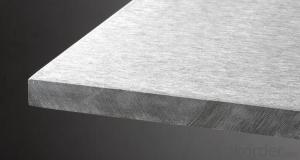

Wall partition Calcium Silicate Board

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specifications

suspended ceiling, partition, heat insulating board, base plate, external wall panel, exterior wall cladding

Calcium Silicate Board is mainly made of siliceous and calcareous materials as major and natural cellulose reinforced, forming in Hatschek process and high pressure (7000 tons and fumigation(in autoclave for 24 hours),Which has the advantages ofhigh strength, light weight, anti- freeze, water-resist, fire-proof, damp-proof, sound-absorption , no distortion and no radiation Used assuspended ceiling, partition, heat insulating board, base plate, external wall panel, exterior wall cladding, paneling, flooring, back-liners, skirting lines, prefabricated structures, door shutters

Application: partition & ceiling in office, supermarket, hotel, hospital, gymnasium, school, stations; interior wallboard in carriage, marine structure, shipping vessel which need fire-proof, heat insulation and damp-proof

Materials: Tobermorite, lime, Quartz sand, wood fiber

Fire-proof rate: A-class incombustible (GB8624-1997)

Incombustibility: 240 minutes (GB/T9978-1999)

Density: 1.2-1.4g/cm3

Moisture: <10%

Heat conduction: 0.24W/MK (Jc/t564) Average

Sound-absorption: 45db (GBJ75-84)

Anti-bend strength: >15MPa (GB/T7019-1997)

Moisture movement rate: <0.19% (GB/T7019-1997)

- Q: The difference between calcium silicate board and plywood

- The use of a long time there are drums, brittle, yellowing, cracking problems, in a fire is not, although it may add fire agent compound, but in high temperature will release toxic gases, so the safety performance is not good, and calcium silicate Board is completely inorganic and wood fiber (asbestos fiber now many manufacturers have no use, radiation) composite, high strength easy processing, life and building life is equal, strong fire resistance, the maximum fire temperature of 1050 degrees.

- Q: Silicon calcium board is mostly used for indoor decoration where.

- Insulation with calcium silicate board, is a hard insulation material, with a light weight, high strength, small thermal conductivity, high temperature, corrosion resistance, can cut, can saw and so on. It is used in power pipeline, metallurgy, petrochemical, construction, ship and other areas of equipment piping, wall roof insulation and fire insulation. Thickness is usually above 30mm, the density of 200-1000kg / m3. Insulation board is white hard, also known as microporous calcium silicate board, the main characteristics of the temperature coefficient of variation is small, thermal conductivity is small, re-processing coefficient, corrosion resistance, good heat insulation, light weight. Used for the wall, in order to keep the room insulation effect. Applications include chemical, marine and metallurgical aspects.

- Q: How to distinguish between the color of calcium silicate board is good or bad

- Color distinction Calcium silicate board is good or bad: Direct visual observation to identify: If the hands of a calcium silicate board of the sample, then look directly at its side, to see the side is not a lot of small white spots, those white spots that is asbestos.

- Q: Jinfu calcium silicate board and Matsumoto easy hair board that kind of good?

- Different types of raw materials, different processes and different production processes processed calcium silicate board used in the range are also different, such as fiber reinforced calcium silicate board using a variety of conditions under the composite wall panels and lightweight partition board, especially for Composite walls of the interior and exterior panels, public buildings and civil buildings of the partition board, as well as ceiling, ceiling. Fiber reinforced calcium silicate board moisture resistance is better, it is also suitable for humid environments, such as bathrooms, kitchens, toilets and basement. At the same time, fiber reinforced calcium silicate board is also suitable for the activities of the ground, can be used for computer room, fire and moisture requirements of the Treasury and warehouses and so on. The calcium silicate board is used for the general houses and commercial ceiling, cut off more common place.

- Q: Gypsum board, Etter board, calcium silicate board, mineral wool board physical properties of what is different, the kind of hotel for the ceiling is more appropriate?

- Ette board for the tile wall, calcium silicate board is better, but the cost is certainly better than the gypsum board, in order to economic effect, the effect is good, with gypsum board

- Q: Calcium silicate with quartz powder is the number of requirements! How much silicon content?

- Calcium silicate board preparation of quartz powder with the general requirements: Silica content: greater than or equal to 93 (%) Melting point 1600 (℃) Mohs hardness: conventional Common specifications: 100 - 325 head Color: gray, grayish yellow Suitable for the production of calcium silicate board and other calcium silicate products

- Q: Calcium silicate board to do the external wall paint how to construction

- In the calcium silicate board (plate) on the gap to be caulking. It is recommended to use the home of the heart of the card to worry about toughness to fill the joints, and then paste the seam (master understand).

- Q: What are the advantages of calcium silicate board?

- The high-rise fire can be seen, because the welding so that the organic insulation layer of fire caused a major fire, if the use of calcium silicate board is absolutely impossible to such a tragedy. Comparison of all building plates, consider the above factors, the most economical is the calcium silicate board.

- Q: Is it harmful to calcium carbonate on home improvement?

- Calcium silicate board consists of a variety of organic and inorganic substances, the use of advanced program-controlled equipment and flow slurry process production molding, high temperature autoclaved curing and special technology processing, is an environmentally friendly, safe, multi-functional high-level building With the plate. Product composition High-purity quartz sand + mica + perlite and other mineral fillers + plant fiber + moderate amount of low-alkali cement

- Q: Why is silicon calcium board not suitable for use in home decoration?

- This is from the decoration style, the material is not appropriate, silicon calcium gypsum board to semi-water gypsum and silicone oil as the main material, the surface of the silicone oil with the transport installation will be out of friction, a long time will be depleted Loss, if you run JS, silicone oil coating is not full, then the moisture effect is even worse, over time the moisture, deformation, mold, yellow is sure

Send your message to us

Wall partition Calcium Silicate Board

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords