C45 Round Bar Carbon Steel Round Bars

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 50000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

C45 Round Bar Carbon Steel Round Bars

Product Description:

(1) Rough Turned

(2) Normalized/Q+T/Annealed

forged round bar 1045

1). Manufacture: EAF+LF+VD(ANNEAL,normalized,peeled,rough turned)

2). Size: 200mm~700mm

3). Length: follow by the requirement of customer(normal length is 3-6m)

4). Inspecting: UTS follows as GB/T6402-91 CLASS 3 or SEP 1921 C/C ,D/d

5). Cut both ends

6). Payment:T/T at sight

7). Chemical:follow the standard which customer offer

8). Delivery: follows by the customer

Chemical Composition:

Grade | C | Si | Mn | P | S | Cr | Ni | B |

1020 | 0.17-0.23 | 0.17-0.37 | 0.35-0.65 | Max 0.030 | Max 0.030 | Max 0.25 | Max 0.30 | 0.0008-0.0030 |

1045 | 0.42-0.50 | 0.17-0.37 | 0.50-0.80 | Max 0.030 | Max 0.030 | Max 0.25 | Max 0.30 | 0.0008-0.0030 |

Appliction:

Steel bar applies to petroleum, chemical industry, electric power, boiler,high temperature resistant,low temperature resistant, corrosion resistant.Carbon steel bar also can be made accroding to the customer's required.

Characteristic:

General purpose medium carbon steel delivered in as rolled condition. It can be further heat treated to achieve specific mechanical properties. The 0.45% carbon content is not favorable for welding. However, it can be weld with appropriate pre and post weld heat treatment. Surface hardness of 57~62 HRC can be achieved with cast hardening to a depth of approximately 1mm. Used for most transmission and motor parts of medium strength. Case hardened parts such as camshafts, gears, rocking levers etc. Simple hand tools and various types of fasteners and fixtures, machinery parts and components with medium stress.

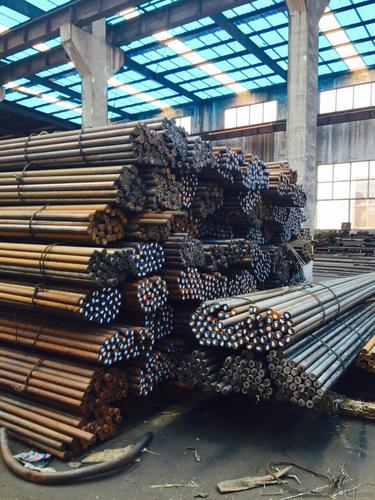

Product Show:

- Q: Can special steel be used in the construction industry?

- Yes, special steel can be used in the construction industry. Special steel is often chosen for its unique properties, such as high strength, durability, and resistance to corrosion. It is commonly used in the construction of buildings, bridges, and infrastructure projects where structural integrity and longevity are crucial. Additionally, special steel can be customized to meet specific project requirements, making it an ideal choice for various construction applications.

- Q: What are the different methods of joining special steel?

- There are several methods of joining special steel, each with its own advantages and limitations. Some of the most common methods include: 1. Welding: This is the most widely used method of joining steel. It involves melting the base material and adding a filler material to create a strong bond. Different welding techniques such as arc welding, gas welding, and laser welding can be used depending on the specific requirements. 2. Brazing: This method involves heating the steel and melting a filler metal with a lower melting point, which then flows into the joint by capillary action. Brazing is often used when joining dissimilar metals or when a lower-temperature joining process is needed. 3. Soldering: Similar to brazing, soldering also uses a lower melting point filler material to join the steel. However, soldering involves melting the filler material without melting the base material. It is commonly used for electrical connections and delicate applications. 4. Mechanical fastening: This method involves joining the steel components using mechanical means such as bolts, screws, rivets, or other types of fasteners. Mechanical fastening is often preferred in situations where disassembly or maintenance is required. 5. Adhesive bonding: Special steel can also be joined using adhesives that create a strong bond between the surfaces. Adhesive bonding is suitable for joining complex shapes, reducing stress concentrations, and providing excellent corrosion resistance. 6. Friction welding: This technique involves rubbing or spinning two steel components together under pressure to generate heat, which then creates a bond. Friction welding is commonly used for joining high-strength or heat-treated steels. 7. Explosive welding: This method involves using explosives to create a high-speed collision between two steel surfaces, resulting in a solid-state bond. Explosive welding is often used for joining dissimilar metals or when high strength and corrosion resistance are required. The choice of joining method depends on factors such as the type of steel, the desired strength and durability of the joint, the specific application requirements, and the available equipment and expertise.

- Q: What are the different methods for improving the creep resistance of special steel?

- Several methods exist to enhance the creep resistance of special steel. One commonly employed technique involves alloying. By incorporating specific alloying elements like chromium, molybdenum, and vanadium, the steel's creep resistance can be significantly improved. These alloying elements create stable carbides or nitrides that serve as obstacles to dislocation movement, thereby reducing the rate of creep deformation. Heat treatment represents another effective approach. By subjecting the steel to carefully controlled heating and cooling processes, the microstructure can be refined to enhance its creep resistance. Techniques such as quenching and tempering aid in the formation of a fine-grained structure, which in turn increases the steel's strength and resistance to creep. Surface modification offers an alternative means of improving creep resistance. Nitriding and carburizing techniques can be utilized to introduce nitrogen or carbon into the steel's surface layer, creating a hardened layer that enhances creep resistance. Moreover, grain size control can be achieved through methods like grain boundary engineering or severe plastic deformation. By refining the grain structure, the movement of dislocations within the material is impeded, resulting in improved creep resistance. Lastly, the application of coatings can also bolster the creep resistance of special steel. Coatings such as ceramic or metallic coatings provide a protective layer that hampers the diffusion of impurities and slows down the creep rate. To summarize, the improvement of creep resistance in special steel can be accomplished through various techniques, including alloying, heat treatment, surface modification, grain size control, and the use of coatings. These methods aim to fortify the steel's microstructure, hinder dislocation movement, and establish protective barriers against creep deformation.

- Q: How does special steel contribute to the strength of products?

- Special steel plays a significant role in enhancing the strength of products in multiple ways. To begin with, engineers design special steel to possess improved mechanical properties, including high tensile strength, toughness, and hardness. These qualities make it particularly suitable for industries such as construction, automotive manufacturing, and aerospace engineering where strength is of utmost importance. Furthermore, special steel can be customized to meet specific requirements, allowing manufacturers to adjust its composition and properties to suit their products. This adaptability guarantees that the steel utilized in different components is optimized for utmost strength, durability, and performance. Additionally, special steel undergoes various heat treatment processes like quenching and tempering, which further bolster its strength. These treatments modify the steel's microstructure, resulting in enhanced hardness and resistance to wear and fatigue. Consequently, products made from special steel can endure heavy loads, harsh environments, and repetitive stress, ensuring their long-term reliability and durability. Moreover, special steel often exhibits remarkable corrosion resistance, making it well-suited for applications exposed to corrosive environments such as the marine or chemical industries. By preventing material degradation, corrosion resistance enhances the overall strength and lifespan of the product. In conclusion, special steel contributes significantly to product strength through its enhanced mechanical properties, customizable composition, heat treatment processes, and corrosion resistance. These factors collectively ensure that products made from special steel can withstand high stress, extreme conditions, and deliver exceptional performance, making them indispensable in various industries.

- Q: What are the specific requirements for special steel used in the marine propeller industry?

- The special steel used in the marine propeller industry must meet specific requirements to ensure optimal performance and durability in harsh marine environments. Some of the key requirements include: 1. Corrosion Resistance: Marine propellers are constantly exposed to saltwater, which can cause corrosion. Therefore, special steel used in the marine propeller industry must have high resistance to corrosion, preventing the formation of rust and maintaining the propeller's integrity over time. 2. Strength and Toughness: Marine propellers are subjected to high mechanical stresses and impacts, especially in rough sea conditions. The special steel used must possess high strength and toughness to withstand these forces without deformation or failure. 3. Fatigue Resistance: Propellers experience cyclic loading due to rotational forces, which can lead to fatigue failure over time. The special steel should have excellent fatigue resistance to withstand millions of load cycles without developing cracks or fractures. 4. Weldability: Propellers are often manufactured in segments and then welded together. The special steel used must be easily weldable, ensuring strong and reliable joints that can withstand the propeller's operational stresses. 5. Heat Resistance: Propellers generate significant heat due to friction and propulsion forces. The special steel should have good heat resistance to prevent deformation or loss of mechanical properties at elevated temperatures. 6. Machinability: Special steel used in the marine propeller industry should be readily machinable to allow for precise shaping and finishing of complex propeller blade designs. 7. Non-Magnetic Properties: Many modern ships utilize magnetic navigation systems and sensors. Therefore, the special steel used in propellers should have low magnetic permeability to minimize interference with these systems. Meeting these specific requirements ensures that the special steel used in the marine propeller industry can withstand the challenging conditions of seawater, provide efficient propulsion, and maintain its structural integrity throughout the propeller's lifespan.

- Q: What are the specific requirements for special steel used in the agricultural sector?

- Optimal performance and durability in the demanding conditions faced by the agricultural sector necessitate specific requirements for the special steel used. Key requirements for special steel in agriculture include: 1. To prevent premature deterioration and ensure a long service life, special steel used in this sector must have high resistance to corrosion, as agricultural equipment often encounters corrosive substances like fertilizers, pesticides, and animal waste. 2. Withstanding heavy loads, impacts, and vibrations during operation, special steel in agriculture must possess high tensile strength and toughness, thereby avoiding deformation or failure. 3. To maintain sharp cutting edges and prevent premature wear caused by abrasive environments with soil, rocks, and debris, special steel used in the agricultural sector should have excellent wear resistance. 4. Special steel in agriculture should have good machinability to enable easy fabrication, welding, and shaping into complex components with intricate shapes and profiles. 5. For agricultural processes involving high temperatures, such as heat treatment or exposure to hot gases, special steel used in these applications should have good heat resistance to retain its mechanical properties and structural integrity, even at elevated temperatures. 6. Balancing performance with cost is crucial for agricultural equipment manufacturers. Hence, special steel used in the agricultural sector should provide a cost-effective solution, offering desired properties at a competitive price. Meeting these specific requirements enables special steel in the agricultural sector to deliver reliable and efficient performance, contributing to the productivity and longevity of agricultural machinery and equipment.

- Q: How is nitrogen alloyed steel used in the production of high-strength bolts?

- Nitrogen alloyed steel is used in the production of high-strength bolts to enhance their mechanical properties. By adding nitrogen as an alloying element, the steel becomes stronger, more resistant to corrosion, and exhibits improved toughness. This makes the bolts suitable for applications requiring high levels of strength and durability, such as in construction, automotive, and aerospace industries.

- Q: How is case-hardening steel used in the manufacturing of gears?

- Case-hardening steel is used in the manufacturing of gears to enhance their durability and strength. The process involves heating the steel to a high temperature and then rapidly cooling it to create a hard outer layer, known as the case, while maintaining a relatively softer core. This hardened surface provides resistance to wear, abrasion, and fatigue, allowing the gears to withstand heavy loads and prolonged use. Additionally, case-hardening steel also improves the gear's ability to withstand impact and retain its shape, ensuring efficient and reliable performance in various mechanical applications.

- Q: What are the specific requirements for special steel used in nuclear applications?

- To ensure the suitability and safety of special steel used in nuclear applications within the demanding nuclear environment, specific requirements must be met. These requirements are designed to maintain the integrity and performance of the steel under various conditions, including extreme temperatures, radiation exposure, and corrosive environments. One primary requirement for special steel in nuclear applications is its need for high strength and toughness. The steel must possess exceptional mechanical properties to withstand the immense pressure and stress it will encounter during operation. This enables the steel to resist deformation, cracking, and failure, ensuring the structural integrity of nuclear components. Another critical requirement is the ability to withstand high temperatures and thermal cycling. Nuclear reactors operate at elevated temperatures, and the steel must retain its mechanical properties even under extreme thermal conditions. This prevents any degradation or loss of strength that could compromise the safety and efficiency of the nuclear system. Furthermore, special steel used in nuclear applications must exhibit exceptional resistance to corrosion and oxidation. The nuclear environment can be highly corrosive due to the presence of various chemicals and coolants, such as water, steam, and coolant gases. The steel must possess a high level of corrosion resistance to prevent any degradation or material loss, which could lead to leaks or failures. Radiation resistance is also a critical requirement for special steel used in nuclear applications. Nuclear reactors emit ionizing radiation, which can damage the structure and properties of conventional materials. Therefore, the steel must have a high resistance to radiation-induced embrittlement and degradation, ensuring its long-term performance in a radioactive environment. Additionally, the steel used in nuclear applications must comply with strict quality control and certification standards. These standards ensure the traceability, material composition, and manufacturing processes of the steel, guaranteeing its reliability and compliance with regulatory requirements. Quality control measures include non-destructive testing, ultrasonic examinations, and material certification. Overall, the specific requirements for special steel used in nuclear applications encompass high strength, toughness, thermal stability, corrosion resistance, radiation resistance, and adherence to stringent quality control standards. Meeting these requirements is crucial to ensure the safe and reliable operation of nuclear systems while mitigating potential risks associated with the nuclear environment.

- Q: How does special steel contribute to the manufacturing of gears?

- Special steel plays a crucial role in the manufacturing of gears due to its unique properties and characteristics. Gears are mechanical devices that facilitate the transmission of power and motion between rotating shafts, and they need to withstand high loads, operate at high speeds, and maintain precise dimensions for smooth and efficient functioning. Special steel, with its enhanced mechanical properties and superior quality, provides the necessary strength, durability, and wear resistance required for gear manufacturing. One key aspect of special steel is its high strength and hardness. Gears often experience heavy loads and undergo significant stress during operation. Special steel, such as alloy steel or tool steel, offers exceptional strength, allowing gears to handle these loads without deformation or failure. Moreover, the hardness of special steel ensures that gears can withstand abrasive wear and prevent damage caused by external factors, such as friction and contact with other components. Special steel also contributes to the manufacturing of gears by providing excellent fatigue resistance. Gears are subject to repetitive cyclic loading, which can lead to fatigue failure over time if not properly designed and manufactured. Special steel, through its unique microstructure and composition, enhances the fatigue life of gears by minimizing the propagation of cracks and reducing the risk of failure, ensuring long-term reliability and performance. Furthermore, special steel offers excellent machinability and dimensional stability, two vital factors in gear manufacturing. The machinability of special steel allows for precise shaping and cutting of gear teeth, ensuring accurate dimensions and smooth gear operation. The dimensional stability of special steel helps maintain the gear's shape and integrity under various temperature and environmental conditions, ensuring the gear's performance remains consistent throughout its lifespan. In conclusion, special steel plays a significant role in the manufacturing of gears by providing the necessary strength, durability, wear resistance, fatigue resistance, machinability, and dimensional stability. Gears made from special steel can withstand high loads, operate at high speeds, and maintain precise dimensions, ultimately contributing to the efficient functioning of various machinery and mechanical systems.

Send your message to us

C45 Round Bar Carbon Steel Round Bars

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 50000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords