Carbon Steel C30/C35/C40/C45/C50/C55/C58 Round Bars

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 30 m.t.

- Supply Capability:

- 120000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Low Carbon Steel C10/C15/C22/C25 Round Bars

Product Description

1, Diameter: 8mm-250mm rounds

5mm-9mm rods

2, Length: 2m, 3m, 5.8m, 6m or customized

3, Standard: GB, ASTM, AISI, SAE, DIN, JIS, EN

OEM technology - send detailed technical parameters for accurate quotation.

2, Produce Process: smelt iron - EAF smelt billet - ESR smelt billet -

hot rolled or forged to get the steel round bar and plate

3, Heat Treatment: annealing, normalizing, tempering, quenching

4, Surface Treatment: Black, Polished, Galvanized

5, Quality Assurance: We accept third party inspection for all orders.

You can ask testing organizations such as SGS, BV, etc. to test our products before shipping.

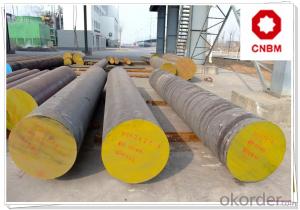

Products Show

Product Overviews

| Product Name | Typical Grades | Diameter(mm) | Standard adopted |

| Carbon Steel | 20 (1020/S20C/C22) | Ø16-Ø300 |

GB/SAE/JIS/DIN

|

| 40 (1040/S40C/C40) | |||

| 45 (1045/S45C/C45) | |||

| Bearing Steel | GCr9 (51100/SUJ1) | Ø12-Ø250 | |

| GCr15 (52100/SUJ2/100Gr6) | |||

| GCr9SiMn (A485-Gr.1/SUJ3) | |||

Cr-Mo Steel | 20Cr (5120/SCr420H/20Cr4) | Ø12-Ø250 | |

| 40Cr (5140/SCr440/41Cr4) | |||

| 42CrMo(4140/SCM440/42CrMo4) | |||

| Gear Steel | 20CrNiMo | Ø16-Ø600 | |

| 20CrMn(5115/SMnC420/20MnCr5) | |||

| 20CrNiMo(8620/SNCM220/20CrMiMo2) |

Work Shop

Company Information

CNBM International Corporation is the most important trading platform of CNBM group.

Whith its advantages, CNBM International are mainly concentrate on Cement, Glass, Iron and Steel, Ceramics industries and devotes herself for supplying high qulity series of refractories as well as technical consultancies and logistics solutions.

FAQ

1, Your advantages?

professional products inquiry, products knowledge train (for agents), smooth goods delivery, excellent customer solution proposale

2, Test & Certificate?

SGS test is available, customer inspection before shipping is welcome, third party inspection is no problem

3, Factory or Trading Company?

CNBM is a trading company but we have so many protocol factories and CNBM works as a trading department of these factories. Also CNBM is the holding company of many factories.

4, Payment Terms?

30% TT as deposit and 70% before delivery.

Irrevocable L/C at sight.

5, Trading Terms?

EXW, FOB, CIF, FFR, CNF

6, After-sale Service?

CNBM provides the services and support you need for every step of our cooperation. We're the business partner you can trust.

For any problem, please kindly contact us at any your convenient time.

We'll reply you in our first priority within 24 hours.

Packaging & Delivery

1, Packaging: seaworthy package or as required

2, Delivery: 35-45 days or based on quantity

- Q: What are the corrosion resistance properties of steel round bars?

- Due to the presence of alloying elements like chromium, nickel, and molybdenum, steel round bars possess exceptional corrosion resistance. These elements combine to form a protective oxide layer on the steel's surface, effectively preventing contact with corrosive substances. By reacting with oxygen in the air, chromium in steel round bars forms a thin, unnoticeable layer of chromium oxide. This layer plays the role of a barrier, shielding the steel from further oxidation and corrosion. Additionally, nickel and molybdenum enhance the corrosion resistance of steel by increasing its ability to withstand pitting, crevice corrosion, and chloride-induced stress corrosion cracking. Apart from alloying elements, the manufacturing process can also impact the corrosion resistance of steel round bars. For example, stainless steel round bars are frequently subjected to passivation, a process that eliminates free iron and other contaminants from the surface. Passivation contributes to the steel's corrosion resistance by creating a clean and inert surface that is less susceptible to corrosion. In conclusion, steel round bars are renowned for their remarkable corrosion resistance, which makes them well-suited for a wide array of applications across various industries, including construction, marine, automotive, and aerospace.

- Q: What are the different types of steel round bar surface defects?

- There are several types of steel round bar surface defects, including pits, roll marks, scratches, cracks, scale, and decarburization.

- Q: What are the different surface coatings available for steel round bars?

- There are several different surface coatings available for steel round bars, including galvanized coatings, epoxy coatings, powder coatings, and chrome coatings.

- Q: Are steel round bars suitable for the production of springs?

- Indeed, springs can be produced using steel round bars. Steel, renowned for its exceptional strength and durability, finds widespread application in spring manufacturing. The circular configuration of these bars facilitates effortless shaping and molding, rendering them an ideal choice for spring production procedures. Steel round bars can be conveniently machined and heat-treated to impart the desired spring attributes, including elasticity and resilience. Furthermore, steel boasts a remarkable tensile strength, enabling it to endure substantial loads. Consequently, it proves well-suited for applications necessitating robust and dependable springs.

- Q: What is the difference between a bright and a hot rolled steel round bar?

- The manufacturing processes and resulting characteristics distinguish a bright steel round bar from a hot rolled steel round bar. To produce a hot rolled steel round bar, the steel billet or ingot is heated to a high temperature and then rolled through a series of rolling mills to achieve the desired shape. As a result, the bar has a rough surface texture with a scale layer on the outside. These bars are commonly used in structural applications where strength and durability are crucial. They have a rough appearance and may require additional processing, such as grinding or machining, to achieve a smooth surface finish. In contrast, a bright steel round bar, also known as a cold drawn or cold finished bar, is created by drawing the hot rolled steel bar through a series of dies at room temperature. This process enhances the dimensional accuracy, surface finish, and mechanical properties of the steel. The resulting bright steel bar has a smooth and shiny surface, devoid of scale or rough texture. These bars are frequently used in applications that require an excellent surface finish and tight dimensional tolerances, such as the production of precision components or for decorative purposes. In conclusion, the primary distinction between a bright and a hot rolled steel round bar lies in their surface finish, dimensional accuracy, and applications. Hot rolled steel bars feature a rough surface texture and are suitable for structural applications, while bright steel bars have a smooth and shiny surface finish, making them ideal for precision or decorative applications.

- Q: What is the resistance to wear of a steel round bar?

- The wear resistance of a steel round bar can vary depending on several factors, including the type of steel used, hardness, surface finish, and any coatings or treatments applied. Steel is widely recognized for its exceptional wear resistance and ability to withstand abrasion and friction. Steel possesses inherent durability and strength, making it resistant to wear from repeated or prolonged contact with other surfaces. Its hardness and strength allow it to resist deformation, chipping, or cracking, even in high-stress situations. This quality makes steel round bars suitable for applications involving heavy loads, constant movement, or abrasive environments. However, it is important to acknowledge that external factors can still influence the wear resistance of a steel round bar. For instance, exposure to corrosive environments or improper handling and maintenance can compromise its wear resistance. In such cases, corrosion or surface damage may occur, resulting in a decrease in overall wear resistance. To enhance the wear resistance of a steel round bar, additional measures can be taken. Heat treatments like quenching and tempering can be employed to improve the hardness and strength of the steel, thereby increasing wear resistance. Furthermore, coatings such as chrome plating or nitriding can be utilized to provide an extra layer of protection against wear, reducing friction and extending the lifespan of the steel round bar. In conclusion, steel round bars generally exhibit high wear resistance due to their inherent durability and strength. However, factors such as steel type, surface finish, coatings, and environmental conditions can impact wear resistance. Proper selection, handling, and maintenance of the steel round bar are crucial to ensuring optimal wear resistance and prolonging its lifespan.

- Q: Are steel round bars suitable for use in the aerospace industry?

- Yes, steel round bars are suitable for use in the aerospace industry. Steel offers high strength and durability, making it ideal for components and structures that require reliability and performance in demanding aerospace applications. Additionally, steel round bars can be customized to meet specific requirements, such as resistance to corrosion, high temperatures, and fatigue.

- Q: What are the different types of steel round bar alloys for improved machinability and strength?

- Some of the different types of steel round bar alloys for improved machinability and strength include free-cutting steel, alloy steel, and tool steel. Free-cutting steel is specifically designed to be easily machinable, allowing for faster and more efficient machining processes. Alloy steel contains various additional elements such as chromium, nickel, or molybdenum, which enhance its strength and wear resistance. Tool steel is a high-performance alloy that is often used in the production of cutting tools and machinery components, offering exceptional hardness and durability.

- Q: How strong are steel round bars compared to other materials?

- Steel round bars, renowned for their exceptional strength and durability, are widely recognized as one of the toughest materials available. In comparison to aluminum, brass, and wood, steel round bars boast a significantly higher tensile strength, referring to their capacity to withstand pulling forces without succumbing to breakage. Moreover, steel round bars are capable of handling higher compressive loads, rendering them highly suitable for applications involving substantial pressure or heavy loads. Not only do steel round bars exhibit remarkable strength, but they also showcase excellent ductility, allowing for easy shaping and bending without any risk of fracture. This remarkable feature grants steel round bars versatility, which explains their extensive utilization in diverse industries such as construction, automotive, manufacturing, and aerospace. While other materials possess their own distinctive properties and applications, steel round bars consistently remain the preferred choice in terms of strength and reliability. Their ability to endure high loads, resist deformation, and maintain structural integrity positions them as a favored option for structural components, shafts, axles, and various other demanding applications.

- Q: How do steel round bars compare to wood round bars?

- Steel round bars have several advantages over wood round bars. Firstly, steel is much stronger and more durable than wood, making steel round bars a more reliable and long-lasting option. Steel round bars also have higher tensile strength, meaning they can withstand greater force without breaking. Additionally, steel is resistant to moisture, rot, and pests, making it a better choice for outdoor or high-moisture environments. On the other hand, wood round bars may be preferred in certain applications for their natural aesthetic appeal and lower cost. Overall, steel round bars offer superior strength, durability, and resistance to environmental factors compared to wood round bars.

Send your message to us

Carbon Steel C30/C35/C40/C45/C50/C55/C58 Round Bars

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 30 m.t.

- Supply Capability:

- 120000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords