C35 Carbon Steel Round Bar C35 Hot Rolled Bars

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 50000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

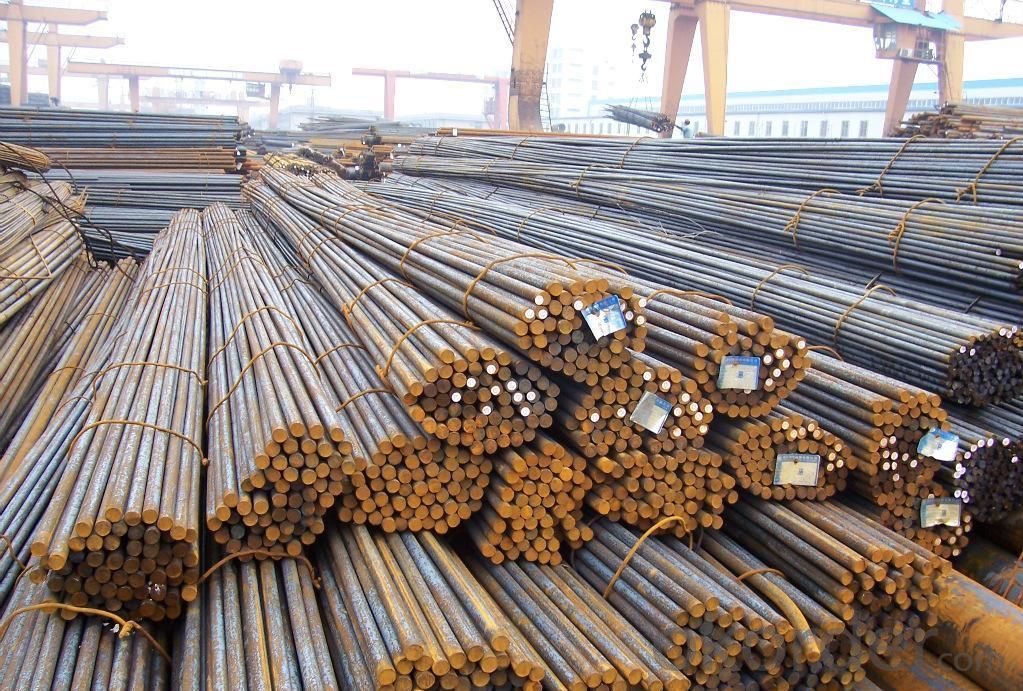

C35 Carbon Steel Round Bar C35 Hot Rolled Bars

Product Description:

1. Sizes: Diameter: 16mm-300mm; Length: 6m, 9m, 12m

2. Grade: 35#, SAE1035, S35C, C35

3. Invoicing on theoretical weight or actual weight as customer’s request

4. Shape: Round bar, solid bar of steel with circular section

5. Technique: Hot rolled, forged, cold rolled

Chemical Composition:

C | Si | Mn | P | S | Ni | Cr | Cu |

0.32-0.40 | 0.17-0.37 | 0.50-0.80 | ≤0.035 | ≤0.035 | ≤0.30 | ≤0.25 | ≤0.25 |

Packing and Delivery:

Packing in bundle with steel strips and shipped by break bulk vessel or container (depend on target market and different ports)

Delivery Detail: Approx.45 days

Usage and Applications

1. C35 Carbon Steel Round Bar C35 Hot Rolled Bars is used in a large number of architectural and engineering structures. Or it can be used in construction of plants for the production of steel house frames, high-voltage transmission towers, bridges, vehicles, boilers, containers, ships, etc.

2. And we can use this kind of product on the performance of the mechanical parts if the demand is not very high.

3. Some especial material steel round bar can be used for main shaft of steamer, hummer shank, with big section and supper force.

Specification:

OD | Length | Material | Standard | Technique |

16-260mm | 6-12m or aques per request | 20# | GB ASTM DIN | Hot rolled |

16-350mm | 35# | |||

200-500mm | 35# | Forged | ||

20-250mm | 20Cr,40Cr,20-42CrMo | Hot rolled | ||

50-300mm | GCr15 |

Main product pictures:

- Q: What are the different quality control measures for special steel production?

- Some of the different quality control measures for special steel production include strict material sourcing and selection, thorough testing and inspection during the manufacturing process, adherence to specific industry standards and specifications, regular calibration and maintenance of equipment, proper handling and storage of finished products, and continuous monitoring and improvement of overall production processes.

- Q: How is special steel used in the production of consumer goods?

- Special steel is used in the production of consumer goods due to its superior strength, durability, and corrosion resistance. It is commonly used in manufacturing appliances, cutlery, automotive components, and construction materials, ensuring the end-products meet high-quality standards and have a longer lifespan.

- Q: Can special steel be used in the production of springs?

- Yes, special steel can be used in the production of springs. Special steel, such as alloy steel or stainless steel, is often preferred for its high strength, durability, and resistance to corrosion, making it suitable for applications where springs need to withstand heavy loads or harsh environments.

- Q: What are the different joining methods used for special steel?

- The different joining methods used for special steel include welding, soldering, brazing, and mechanical fastening. Welding involves melting the base metal and adding a filler material to create a strong bond. Soldering and brazing use lower temperatures to join the steel using a filler material with a lower melting point. Mechanical fastening methods include bolts, nuts, screws, and rivets, which provide a secure connection without altering the base metal's properties.

- Q: What are the advantages of using special steel in aerospace applications?

- There are several advantages of using special steel in aerospace applications. Firstly, special steel offers exceptional strength and durability, making it suitable for withstanding the extreme conditions and stresses experienced during flight. This ensures the structural integrity and safety of the aircraft. Secondly, special steel has excellent corrosion resistance properties, which is crucial for protecting the aircraft components from the harsh environment and moisture encountered in the aerospace industry. Additionally, special steel can be tailored to meet specific requirements such as high-temperature resistance or low weight, allowing for efficient design and optimization of aerospace components. Lastly, special steel is readily available and cost-effective, making it a practical choice for aerospace manufacturers. Overall, the use of special steel in aerospace applications enhances the performance, reliability, and longevity of aircraft components.

- Q: Can special steel be used in the oil and gas equipment manufacturing industry?

- Yes, special steel can be used in the oil and gas equipment manufacturing industry. Special steel, such as stainless steel or alloy steel, offers high strength, corrosion resistance, and durability, making it suitable for various applications in the oil and gas sector. It is commonly used in the manufacturing of pipes, valves, fittings, and other critical components that can withstand harsh operating conditions and prevent leakage or failure.

- Q: How is special steel used in the manufacturing of consumer goods?

- Special steel is used in the manufacturing of consumer goods in various ways. One of the key applications is in the production of high-quality kitchen knives and utensils. Special steel, such as Damascus steel or stainless steel, is preferred for its exceptional strength, durability, and corrosion resistance. These properties ensure that the consumer goods made from special steel can withstand the demands of everyday use, retain their sharpness for longer periods, and resist rust and staining. Another significant use of special steel in consumer goods manufacturing is in the production of watch components. Special steel, particularly stainless steel, is widely used in the manufacturing of watch cases, bezels, and bracelets due to its appealing aesthetics and resistance to scratches and tarnishing. Additionally, special steel alloys are often used for the production of watch springs, which require high strength, elasticity, and resistance to fatigue. Furthermore, special steel finds application in the manufacturing of consumer goods like automotive parts, hand tools, and firearms. In the automotive industry, special steel is used for producing engine components, chassis parts, and suspension systems, among others. The high strength, impact resistance, and heat resistance of special steel make it suitable for these applications, ensuring the durability and reliability of consumer goods. Special steel also plays a crucial role in the production of hand tools, such as wrenches, pliers, and screwdrivers. These tools require strong and durable materials to withstand the forces applied during use. Special steel meets these requirements, providing the necessary strength and resistance against wear and tear. Lastly, special steel is utilized in the manufacturing of firearms, where it is highly valued for its strength, impact resistance, and heat resistance. Firearms need to withstand high pressures and temperatures generated during firing, making special steel an ideal choice for barrels, chambers, and other critical components. In summary, special steel is used in the manufacturing of consumer goods such as kitchen utensils, watches, automotive parts, hand tools, and firearms. Its exceptional properties, including strength, durability, corrosion resistance, and heat resistance, make it a preferred material for these applications, ensuring high-quality and long-lasting products for consumers.

- Q: Does special steel have any magnetic properties?

- Yes, special steel can have magnetic properties, depending on its composition and treatment. Steel is primarily composed of iron, and iron is a ferromagnetic material, meaning it can be magnetized. However, the presence of other elements such as nickel, cobalt, and certain alloys can affect the magnetic properties of steel. For instance, stainless steel, which contains chromium and nickel, is generally non-magnetic or only weakly magnetic. On the other hand, materials like tool steel or high-speed steel can exhibit stronger magnetic properties due to their composition and heat treatment. Therefore, it is important to consider the specific type of special steel and its alloying elements when determining its magnetic properties.

- Q: What are the different chemical processing grades of special steel?

- There are several different chemical processing grades of special steel, including stainless steel, tool steel, high-speed steel, and alloy steel.

- Q: What is the tensile strength of special steel?

- The tensile strength of special steel can vary depending on its specific composition and manufacturing process. However, special steel is generally known for its high tensile strength, often exceeding 1000 MPa (mega pascals), making it suitable for applications requiring strong and durable materials.

Send your message to us

C35 Carbon Steel Round Bar C35 Hot Rolled Bars

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 50000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords