Bending Aluminum Sheets - Aluminum Sheet Thickness in All Kinds Supply

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 100000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

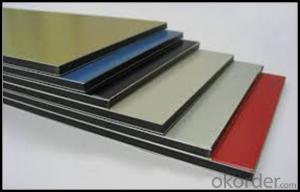

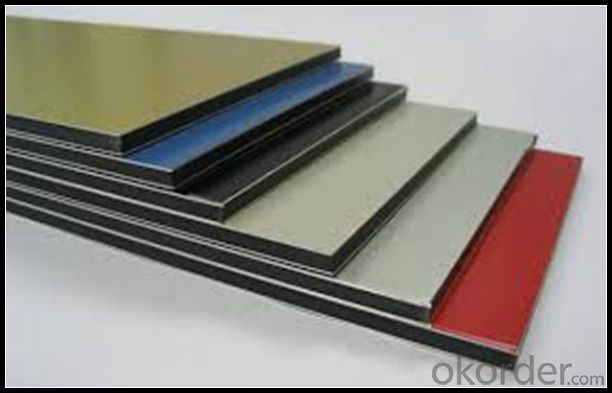

1.Structure of Aluminum Sheet Thickness in All Kinds Supply

Aluminum Sheets are strengthened and cut from raw materials with different alloys, such as AA5005, AA5052, etc. They are easy for processing in different shapes, good in intensity and can be quickly installed. Aluminium Sheets for Energy Saving Curtain Walls are good in energy saving, weather resistance, fire resistance, easy for maintenance and with many colors.

Aluminium Sheets for Energy Saving Curtain Walls are widely used in construction of metal walls, metal ceilings, car decoration, advertizing panels, etc.

2.Main Features of Aluminum Sheet Thickness in All Kinds Supply

•High intensity

•Easy to be processed and shaped

•Weather resistance

•Anti-pollution & environment protection

3. Aluminum Sheet Thickness in All Kinds Supply Images

4.Specification of Painted Aluminum Sheet for Composite Panels

Alloy Number | AA5XXX |

Temper | H12, H14, H16, H18, H22, H24, H26, H32, HO, F |

Thickness | 0.1mm – 500mm |

Width | 10mm- 2200mm |

Standard | GB/T3880-2006, ASTM, ISO, EU standard |

5.FAQ

A.What about inspections to guarantee quality?

For each order for Aluminum Sheets with Mill Finished Surface AA5XXX, we will arrange strict inspection for raw materials, inspection during production and inspection for finished goods.

With requirement of customers, we also can arrange the third party inspection.

B.What about delivery?

We will put order for Aluminum Sheets with Mill Finished Surface AA5XXX in production schedule after order gets confirmed against copy of TT or L/C. Normally it takes about one month for production. Exact shipment schedule is different based on different sizes and quantity.

C.What is the MOQ?

5 tons for each size.

D. Where have you exported aluminium sheets?

We have exported aluminum sheets to many countries. Main markets include South East Asia, Middle East, North America, South America, etc.

- Q: how to process 0.3mm hole on aluminum material?

- punching wire-electrode cutting

- Q: What are the different methods of finishing aluminum sheet edges?

- There are several methods for finishing aluminum sheet edges, including filing, sanding, deburring, chamfering, and using edge trim or molding.

- Q: I had this mandarin orange can. I filled the can with water. Four days later, there are quarter inch thick rust cakes on the inside of the can. Since I assume the can is aluminum, are these cakes aluminum oxide? If so, is it flammable and/or dangerous?

- Mandarin orange cans are not generally made of aluminum. Most likely, it is steel with a tin coating on it. Aluminum oxide does not turn red, most likely this is iron oxide, otherwise known as rust metal oxides are not flamable. Heavy metals are hazardoues (lead, lead oxide...), but iron oxide is not, in fact, it's important to have iron in your diet, it is what makes your blood work! Astrobuf

- Q: What are the different types of aluminum sheets available in the market?

- There are several different types of aluminum sheets available in the market, each with its own unique characteristics and applications. Some of the most common types include: 1. Plain Aluminum Sheet: This is the most basic and widely used type of aluminum sheet. It is known for its excellent corrosion resistance and high strength-to-weight ratio. Plain aluminum sheets are commonly used in construction, automobile manufacturing, and aerospace industries. 2. Painted Aluminum Sheet: These sheets are coated with a layer of paint to enhance their aesthetic appeal and protect the underlying aluminum from environmental elements. Painted aluminum sheets are commonly used in architectural applications, signage, and decorative purposes. 3. Perforated Aluminum Sheet: This type of aluminum sheet features perforations or holes throughout its surface. It is often used in architectural projects, industrial filtration systems, and ventilation applications. 4. Embossed Aluminum Sheet: These sheets have a textured or patterned surface, created by embossing or rolling the aluminum. Embossed aluminum sheets are frequently used for decorative purposes, such as interior design, signage, and packaging. 5. Anodized Aluminum Sheet: Anodizing is an electrochemical process that forms a protective oxide layer on the surface of the aluminum. Anodized aluminum sheets are highly resistant to corrosion and abrasion, making them suitable for outdoor applications, such as building facades and automotive parts. 6. Tread/Diamond Plate Aluminum Sheet: This type of aluminum sheet features raised diamond or tread patterns on its surface, providing enhanced grip and traction. Tread/diamond plate aluminum sheets are commonly used in transportation, flooring, and staircases. Additionally, aluminum sheets are available in various thicknesses, sizes, and alloys, such as 3003, 5052, and 6061. The specific type of aluminum sheet required depends on the intended use and specific requirements of the project.

- Q: Is it suitable to use aluminum sheets as roofing materials in areas with high temperatures?

- <p>Yes, aluminum sheets can be used for roofing materials in hot climates. Aluminum has a high thermal conductivity, which means it can quickly dissipate heat, helping to keep buildings cooler. It also has excellent resistance to corrosion, which is beneficial in areas with high humidity or salt air. Additionally, aluminum is lightweight, easy to install, and can be recycled, making it an environmentally friendly option. However, it's important to ensure proper ventilation and insulation to maximize its performance in hot climates.</p>

- Q: On the web page to see more information on the plating aluminum plate, I do not know what is the difference between aluminized and aluminum plating performance?

- Hot dip aluminizing applicationsAluminized steel is widely used. The type I aluminized steel plate, originally developed, is mainly used in automobile exhaust pipes and silencers. Type II is used mainly for roofing and side walls of buildings, as well as for chemical containers. The aluminized steel wire produced by the new process is expected to be used as the core of the transmission line instead of the galvanized steel wire. Aluminized steel pipe has been widely used in power plants, boilers, water wall tubes, steam pipes, heat exchangers and so on. Aluminized steel structure has been widely used in power transmission tower, told highway guardrail and so on.

- Q: This question asks for a list of various methods used to treat the surface of aluminum sheets to improve their properties or appearance.

- <p>There are several types of surface treatment for aluminum sheets, each serving different purposes. These include: Anodizing, which creates a protective oxide layer and enhances corrosion resistance; Chemical Conversion Coating, such as chromate conversion, to improve paint adhesion and corrosion resistance; Electrolytic Polishing, which provides a smooth, shiny surface; Powder Coating, an electrostatic process that applies a durable coating; Paint Coating, offering a wide range of colors and finishes; and Mechanical Polishing, which smooths the surface and improves reflectivity. Each treatment has its specific applications and benefits, depending on the desired outcome for the aluminum sheet.</p>

- Q: The user is asking if aluminum sheets can be used as a substitute for metal siding in construction.

- <p>Yes, aluminum sheets can be used to replace metal siding. They are lightweight, durable, and resistant to corrosion, making them a popular choice for siding. Aluminum sheets can be painted or finished to match various architectural styles and are low maintenance. However, it's important to ensure that the aluminum sheets are of the appropriate gauge and quality for the application, and that they are installed correctly to ensure longevity and performance.</p>

- Q: 5052 can aluminum plate be machined with laser cutting machine?

- Can cut, but the incision does have cut marks, if processing 3 mm below the thickness, incision quality will be better.

- Q: How do you prevent discoloration of aluminum sheets?

- To prevent discoloration of aluminum sheets, it is important to apply a protective coating or finish to the surface. This can include using clear lacquer or anodizing the aluminum, which creates a durable oxide layer that resists corrosion and discoloration. Regular cleaning and maintenance, avoiding harsh chemicals, and protecting the aluminum from exposure to extreme temperatures can also help prevent discoloration.

Send your message to us

Bending Aluminum Sheets - Aluminum Sheet Thickness in All Kinds Supply

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 100000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords