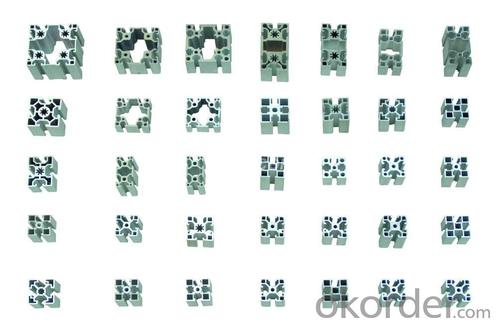

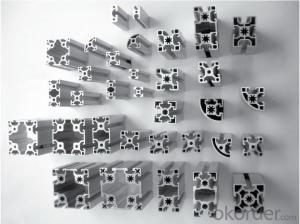

Bosch Aluminum Extrusion Profiles for LED Light Strips

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Aluminium is a relatively soft, durable, lightweight, ductileand malleablemetalwith appearance ranging from silvery to dull gray, depending on the surfaceroughness. It is nonmagnetic and does not easily ignite. A fresh film ofaluminium serves as a good reflector (approximately 92%) of visible lightand an excellent reflector (as much as 98%) of medium and far infraredradiation. The yield strength of pure aluminium is 7–11 MPa,while aluminium alloys have yield strengths ranging from200 MPa to 600 MPa. Aluminium has about one-third the densityand stiffness of steel. It is easily machined,cast, drawn and extruded.

Aluminium alloys (or aluminum alloys; see spellingdifferences) are alloysin which aluminium(Al) is the predominant metal. The typical alloying elements are copper, magnesium,manganese,silicon,tin and zinc. There are twoprincipal classifications, namely casting alloys and wrought alloys, both of which are furthersubdivided into the categories heat-treatableand non-heat-treatable. About 85% of aluminium is used for wrought products,for example rolled plate, foils and extrusions.Cast aluminium alloys yield cost-effective products due to the low meltingpoint, although they generally have lower tensile strengthsthan wrought alloys. The most important cast aluminium alloy system is Al–Si,where the high levels of silicon (4.0–13%) contribute to give good castingcharacteristics. Aluminium alloys are widely used in engineering structures andcomponents where light weight or corrosion resistance is required

Features:

Material | Alloy 6063,6061,6005or according to customer’s choice |

Temper | T3, T4, T5, T6 |

Surface | Anodize, electrophoresis, powder coating, PVDF coating, wood grain painting, matted, etc. |

Length | Coating 6.5 meters, Anodizing 6.5 meters, Mill finish 5 meters |

Application | Industrial, electrical equipment(TV set, air conditioner, refrigerator, computer), decoration,construction, transportation |

Custom Made | We can package following with customer's request. |

FAQ:

1. What is the form of payment?

Normally 30% TT, L/C at sight

2. Type of quotation?

FOB, CFR, CIF

3. Port of loading?

Shenzhen/Guangzhou port

4. Delivery time?

15-20 days after client’s deposit

- Q: What are the safety features of aluminum profiles in construction?

- Aluminum profiles in construction offer a range of safety features that make them a popular choice for various applications. First and foremost, aluminum profiles are lightweight yet durable, making them easy to handle and install while still providing structural integrity. This reduces the risk of accidents or injuries during the construction process. Additionally, aluminum profiles are non-combustible, meaning they do not contribute to the spread of fire. This is a crucial safety feature in construction, as it helps to minimize the potential for fire-related hazards and ensures the safety of occupants. Aluminum profiles also have excellent corrosion resistance properties. They are naturally resistant to rust and decay, which means they can withstand harsh environmental conditions and maintain their structural integrity over time. This is particularly important in coastal or humid areas where the risk of corrosion is higher. Furthermore, aluminum profiles can be designed to incorporate safety features such as non-slip surfaces or grooves for enhanced grip and stability. This is especially beneficial in applications where slip and fall accidents may occur, such as staircases or walkways. Aluminum profiles also offer excellent electrical conductivity, which can be advantageous when considering safety in electrical installations. Their high thermal conductivity helps dissipate heat efficiently, reducing the risk of overheating or electrical malfunctions. Lastly, aluminum profiles are recyclable, which aligns with sustainable construction practices. By using aluminum profiles, construction projects can contribute to reducing waste and environmental impact. Overall, the safety features of aluminum profiles in construction include their lightweight yet durable nature, non-combustibility, corrosion resistance, ability to incorporate non-slip surfaces, excellent electrical conductivity, and recyclability. These features combine to create a safe and sustainable construction material choice.

- Q: What are the surface hardness properties of aluminum profiles?

- The surface hardness properties of aluminum profiles can vary depending on the specific alloy and treatment processes applied. Aluminum alloys are generally known for having a lower hardness compared to other metals such as steel. However, through various treatments, aluminum profiles can achieve improved surface hardness. One common treatment method is anodizing, which involves creating an oxide layer on the surface of the aluminum. This process not only enhances the corrosion resistance of the profiles but also increases their surface hardness. Anodized aluminum profiles can have a hardness ranging from 150 to 300 HV (Vickers hardness), depending on the thickness of the oxide layer. Another treatment process is hard coating, where a ceramic material such as aluminum oxide is applied to the surface of the profiles. This coating significantly enhances the hardness of the aluminum, providing a greater level of wear resistance. The hardness of hard-coated aluminum profiles can range from 400 to 600 HV or even higher. It is important to note that the specific hardness properties can vary depending on the alloy composition, surface treatment method, and the desired application of the aluminum profiles. Therefore, it is crucial to consult with manufacturers or suppliers to determine the appropriate hardness properties that best suit your specific needs.

- Q: Can aluminum profiles be used for lighting fixtures or systems?

- Yes, aluminum profiles can be used for lighting fixtures or systems. Aluminum is a lightweight and durable material that is commonly used in the construction of lighting fixtures due to its excellent thermal conductivity and corrosion resistance. Aluminum profiles can be easily shaped and customized to meet the specific design requirements of lighting systems, making them a popular choice in the industry.

- Q: What does "T" in the aluminum profile 6063-T5 mean?

- China's current general is the United States Aluminum Association "Aluminium Association" numberT5By cooling the high temperature molding process, and then the artificial aging state. Applied by cooling high temperature molding process, not through the cold processing (for straightening and leveling, but does not affect the mechanical properties of the limit), to artificial aging products.

- Q: Can aluminum profiles be used for escalator steps?

- Yes, aluminum profiles can be used for escalator steps. Aluminum is a lightweight and durable material that can withstand the weight and constant movement associated with escalator steps. Additionally, aluminum profiles can be easily customized and shaped to fit the specific design requirements of escalators.

- Q: Can aluminum profiles be utilized in high-rise constructions that incorporate large windows?

- <p>Yes, aluminum profiles are commonly used in high-rise buildings with large windows due to their strength, durability, and lightweight properties. They offer excellent resistance to corrosion and weathering, making them ideal for external applications. Additionally, aluminum profiles can be easily customized to fit various window designs and sizes, providing both aesthetic and functional benefits. Their thermal break technology also helps in reducing heat transfer, enhancing energy efficiency in buildings.</p>

- Q: Are aluminum profiles suitable for use in the renewable energy industry?

- Yes, aluminum profiles are suitable for use in the renewable energy industry. Aluminum is lightweight, durable, and corrosion-resistant, making it ideal for applications such as solar panel frames, wind turbine components, and electrical infrastructure. It also offers excellent thermal conductivity and recyclability, aligning with the sustainability goals of the renewable energy sector.

- Q: What are the different assembly options available for aluminum profiles?

- There are several assembly options available for aluminum profiles, depending on the specific requirements and applications. Some of the common assembly methods include: 1. Mechanical Fastening: This involves using screws, bolts, or rivets to join two or more aluminum profiles together. Mechanical fastening provides a strong and secure connection and is suitable for applications that require frequent disassembly or adjustment. 2. Welding: Aluminum profiles can be welded together using various welding techniques such as TIG (Tungsten Inert Gas) welding or MIG (Metal Inert Gas) welding. Welding provides a seamless and strong joint, making it ideal for applications that require maximum strength and rigidity. 3. Adhesive Bonding: Adhesive bonding involves using adhesives or glues to join aluminum profiles together. This method is suitable for lightweight applications or where aesthetics are important, as it provides a clean and seamless appearance without visible fasteners. However, adhesive bonding may not be as strong as mechanical fastening or welding. 4. Slotting and Connecting Elements: Aluminum profiles often have T-slot designs that allow the use of various connecting elements such as T-nuts, connectors, and brackets. These elements can be easily inserted into the slots and tightened to create a secure and adjustable joint. This method is particularly useful for applications that require flexibility and easy reconfiguration. 5. Corner Brackets: Corner brackets are specifically designed to connect aluminum profiles at right angles. These brackets can be easily attached using screws or bolts and provide a strong and rigid joint. Corner brackets are commonly used in frame construction or for creating corners in structural applications. 6. Interlocking Systems: Some aluminum profiles feature interlocking systems that allow them to be connected without the need for additional fasteners or connectors. These systems use specially designed shapes or grooves that fit together, providing a secure connection. Interlocking systems are often used in modular structures or systems that require quick assembly and disassembly. Overall, the choice of assembly method for aluminum profiles depends on factors such as strength requirements, aesthetics, ease of assembly, and the specific application or industry. It is important to carefully consider these factors to select the most suitable assembly option for a given project.

- Q: This question asks for guidance on selecting the appropriate size and shape of aluminum profiles for a specific application.

- <p>Choosing the right size and shape of an aluminum profile involves several steps. First, consider the load-bearing requirements and structural integrity needed for your application. Consult with engineering standards or use software that can simulate the stress and load on the profile. Second, consider the aesthetic and functional requirements, such as the profile's visibility and the need for specific features like slots or holes. Third, review the available profiles from suppliers, matching your needs with their offerings. Finally, prototype with the selected profile to ensure it meets all requirements before full-scale production. Always consult with aluminum profile manufacturers or suppliers for their expertise and recommendations.</p>

- Q: Can aluminum profiles be custom-designed or customized?

- Aluminum profiles have the ability to be tailored or personalized to meet specific demands. Aluminum is a remarkably adaptable material that can be easily molded and shaped into a variety of forms. By customizing aluminum profiles, it becomes possible to create distinct shapes, sizes, and finishes that fulfill the precise requirements of various applications. The customization and custom design of aluminum profiles encompass a range of possibilities. This can involve modifying dimensions, crafting intricate shapes, adding slots or holes for assembly, incorporating specific features or accessories, and even applying diverse surface treatments or coatings. Such design flexibility permits the utilization of aluminum profiles in numerous industries and applications, including construction, automotive, aerospace, electronics, and many more. The process of customizing aluminum profiles typically involves a collaborative effort between the manufacturer and the customer. The manufacturer works closely with the customer to comprehend their requirements, provide technical support, and propose design solutions that align with their specific needs. This collaboration may entail creating prototypes, conducting tests, and making adjustments until the desired custom design is achieved. In conclusion, aluminum profiles can indeed be custom-designed or customized to cater to specific requirements, rendering them a favored choice for numerous industries seeking distinctive and tailored solutions.

Send your message to us

Bosch Aluminum Extrusion Profiles for LED Light Strips

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords