Aluminum Extrusion Profiles Japanese for LED Strips Lighting Project

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 5000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Structure of Aluminium Profile for Led Strips Lighting Project From Description:

We have more than 10 years experiences on manufacturing kinds of aluminum profiles, such as Aluminum Window & Door profiles, Aluminum tile trim profiles, Aluminum profiles for LED light, Round/Square General profiles, Aluminum heat sink, Aluminum heating insulation profiles, Curtain wall Aluminum profiles, and others Industry profiles.

Our products have exported to all over the world, and we also have a large of market share in Algeria, Angola, Philippine, Guinea, Ghana, South Africa, Nepal, Nigeria, Tanzania, Iraq etc.

Main Features of the Aluminium Profile for Led Strips Lighting Project From:

1, Strong R&G: help customers finalize the design, strong tool design ability, excellent, pressing and surface treatment technology;

2, Strong quality management: ISO&SGS SYSTEM;

3, 24 hours on-line communication, professional, patient, flexible;

4, High capacity of manufacturing and wide range of products;

5, We can provide secondary manufacturing.

6, High corrosion resistance, high weather resistance and good wear resistance.

7, Alternative surface treatment: Colorful ANODIZE, POWDER COATING, ELECTROPHORESIS & WOODEN GRAIN. Plentiful colors upon your needs.

8, Excellent material for smooth and subtle edges, elegant appearance.

9, Strong coated adhesion which is suitable for construction and industrial material.

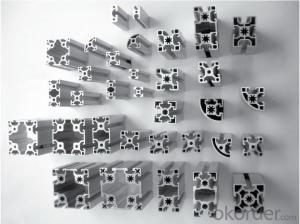

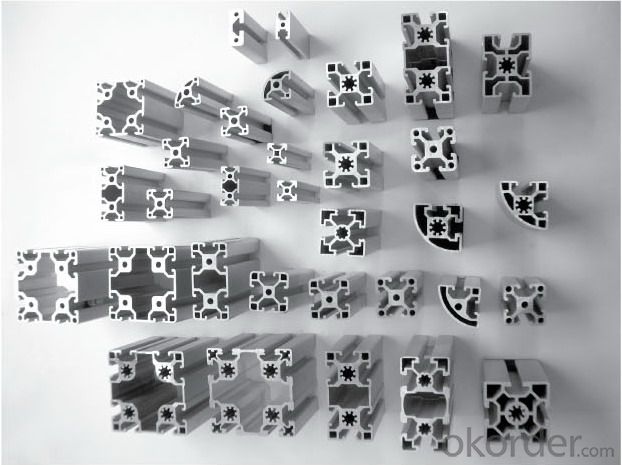

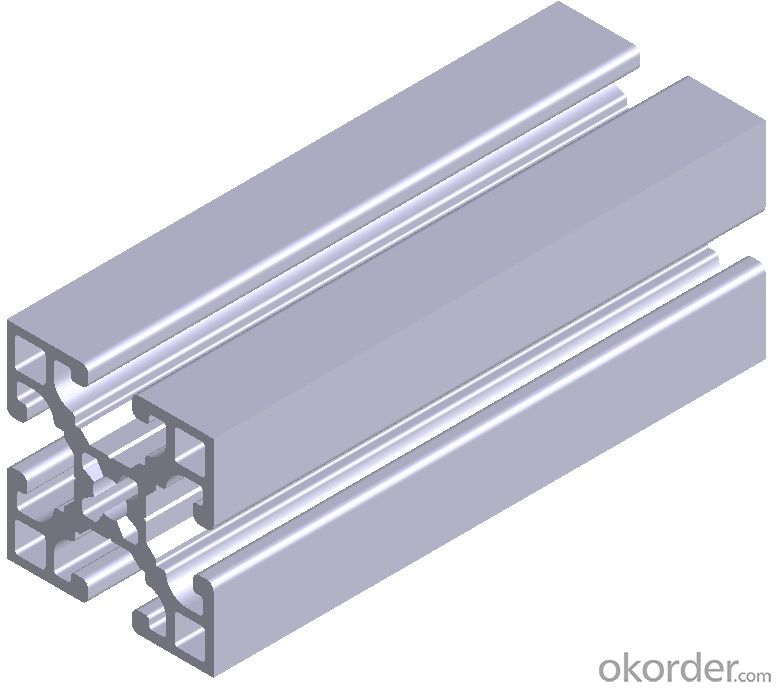

Images of the Aluminium Profile for Led Strips Lighting Project From:

Aluminium Profile for Led Strips Lighting Project From Specification:

Material | Alloy Aluminum 6063,6061,6005 or customer nominated |

Temper | T3, T4, T5, T6 |

Surface | Anodize, electrophoresis, powder coating, PVDF coating, wood grain painting, matted, etc. |

Colour | Any colour based on Standard Germany RAL Mark |

Length | Coating 6.5 meters, Anodizing 6.5 meters, Mill finish 5 meters |

Press Machine | 500-4000 tons all together 64 press lines. |

Fabrication | 1. Windows and doors; 2. Drilling; 3. Bending; 4. Cutting; 5. etc. |

Certificate | ISO 9001 |

Moulding | 1. Using our moulds, no fee; |

2. Using customer drawing, opening mould, usually about 10~50 tons then the moulding can be refunded. | |

3. Mould cost is negotiable base on the order quantity | |

Capability | Annual output 100,000 tons |

FAQ:

1.Q: What about leadtime ?

A: Normally the leadtime is 60days after we receive the deposit and confirm the details. All the press machines we use is the best quality in China Yangli brand. The press machine leadtime from Yangli is 50days, the best leadtime we can give is 60days.

2.Q: What's the lead time for moulds?

A: Normally the mould leadtime is 45 days after we confirm all the details with customer. Our professional mechanical enginners from Austria will design the mould according to the samples from customer, or by the specifications offered by customers.

3.Q:What kinds of mould you can make? and what is your strong point for the moulds?

A: we can make wrinkle wall mould and smooth wall mould both. For wrinkle wall mould we can make, 79" pan, fish pan, bbq pan. For smooth wall mould we can make muffin cup, and cake cup, tar cup,etc. We can also make 2 or 3 portion conatiner moulds as long as you offer us sample or specifications. Our strong points are all our moulds are WEDMLS cut, which makes the mould more accurate and precise. Important materials likestainless steel parts we make in Austria. We also recut after heat treatment, which most of makers do not take this process.

- Q: Is it possible to recycle aluminum profiles and use them again in construction projects?

- <p>Yes, aluminum profiles can be recycled and reused in construction. Aluminum is highly recyclable, and the recycling process requires significantly less energy compared to the production of new aluminum. Recycled aluminum maintains its properties, making it suitable for various construction applications. This practice not only conserves resources but also reduces waste and environmental impact.</p>

- Q: Is it possible to utilize aluminum profiles for constructing exterior railings and staircases?

- <p>Yes, aluminum profiles can be used for exterior railings and staircases. They are known for their durability, resistance to corrosion, and low maintenance requirements, making them ideal for outdoor applications. Aluminum's strength and lightweight properties also contribute to its suitability for these structures. However, it's important to ensure that the aluminum is of high quality and properly treated to withstand weather conditions and ensure longevity.</p>

- Q: What are the advantages of utilizing recycled aluminum in construction projects in terms of environmental impact?

- <p>Using recycled aluminum profiles in construction offers significant environmental benefits. It conserves natural resources by reducing the need for mining bauxite, which is the primary source of aluminum. This reduction in mining decreases habitat destruction and soil erosion. Additionally, recycling aluminum requires significantly less energy compared to producing it from raw materials, which cuts down on greenhouse gas emissions and reduces the overall carbon footprint. Furthermore, the use of recycled aluminum helps in waste management by diverting materials from landfills, thereby reducing pollution and the environmental burden of waste disposal.</p>

- Q: What are the various materials incorporated in the production of aluminum profiles?

- <p>Aluminum profiles are primarily made from aluminum alloys, which can include different elements to enhance properties such as strength, corrosion resistance, and machinability. Commonly used alloys are 6063, 6061, and 6082. Other materials may include magnesium, silicon, copper, manganese, and zinc, which are added to achieve specific alloy characteristics. Some profiles may also incorporate reinforcing materials like fiberglass or steel for added strength, or coatings such as anodized layers, powder coating, or paint for improved aesthetics and corrosion resistance.</p>

- Q: Are aluminum profiles suitable for conveyor rollers?

- Yes, aluminum profiles are suitable for conveyor rollers. Aluminum is a lightweight and durable material that offers various advantages for conveyor systems. Firstly, aluminum profiles provide excellent strength-to-weight ratio, making them ideal for conveyor rollers. They are strong enough to handle the weight of materials being transported while being light enough to reduce the overall weight of the conveyor system, resulting in energy savings and easier handling during installation and maintenance. Additionally, aluminum profiles offer excellent corrosion resistance, which is crucial for conveyor systems operating in harsh environments, such as those exposed to moisture or chemicals. This corrosion resistance ensures the longevity and reliability of the conveyor rollers, reducing maintenance requirements and costs. Moreover, aluminum profiles can be easily customized and fabricated to fit specific conveyor system requirements. They can be extruded into various shapes and sizes, allowing for the creation of conveyor rollers that perfectly match the application's needs. This versatility makes aluminum profiles highly adaptable and suitable for a wide range of conveyor systems, including those in industries such as manufacturing, packaging, and logistics. Furthermore, aluminum is a highly sustainable material as it is 100% recyclable, making it an environmentally friendly choice for conveyor rollers. By using aluminum profiles, companies can contribute to their sustainability goals and reduce their carbon footprint. In conclusion, aluminum profiles are indeed suitable for conveyor rollers due to their lightweight, durable, corrosion-resistant, customizable, and sustainable properties.

- Q: Can aluminum profiles be used in the production of consumer electronics?

- Yes, aluminum profiles can be used in the production of consumer electronics. Aluminum is a lightweight and durable material that offers excellent heat dissipation properties, making it suitable for electronic devices that require efficient cooling. Additionally, aluminum profiles can be easily customized and integrated into various designs, providing flexibility for manufacturers in creating sleek and stylish consumer electronics products.

- Q: How do aluminum profiles perform in terms of corrosion resistance?

- The outstanding corrosion resistance of aluminum profiles is well-known, attributed to the formation of a protective oxide layer on the surface. This oxide layer effectively shields against corrosion, even in challenging environments, acting as a barrier to halt further oxidation and corrosion. Moreover, the corrosion resistance of aluminum profiles can be further improved through diverse surface treatments like anodizing or powder coating, offering supplementary defense against corrosion. Consequently, aluminum profiles possess remarkable corrosion resistance, rendering them ideal for a vast array of applications in industries such as construction, transportation, and manufacturing.

- Q: Are aluminum profiles suitable for outdoor sign applications?

- <p>Yes, aluminum profiles are commonly used for outdoor signage due to their durability, resistance to corrosion, and lightweight properties. They can withstand various weather conditions without rusting or fading, making them an ideal material for long-lasting outdoor signs. Aluminum profiles can be easily cut, shaped, and assembled, offering flexibility in design and functionality.</p>

- Q: Can aluminum profiles be used for electrical bus ducts?

- Yes, aluminum profiles can be used for electrical bus ducts. Aluminum is a suitable material for bus ducts as it is lightweight, corrosion-resistant, and has good electrical conductivity. Additionally, aluminum profiles can be easily fabricated and installed, making them a popular choice for electrical bus ducts in various industries.

- Q: I would like to know where Urumqi has industrial aluminum profiles, such as 3030, 4040, 3060 aluminum, etc., note that industrial aluminum, not doors and windows, aluminum profiles, the difference between the two very large!

- And shares in the east railway station there, the east railway station and then go one Station Road (near the North Main Road) can see.

Send your message to us

Aluminum Extrusion Profiles Japanese for LED Strips Lighting Project

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 5000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords