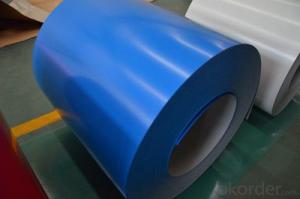

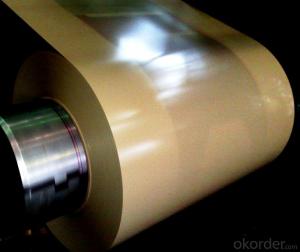

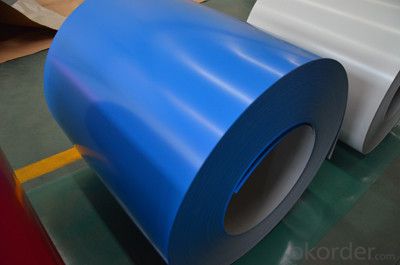

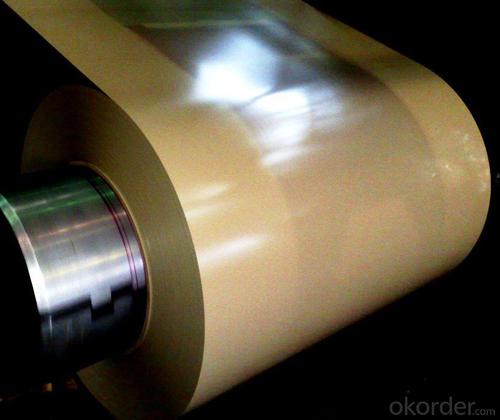

BMP Z21 PPGI Rolled Steel Coil for Roofing Constrution

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m.t.

- Supply Capability:

- 30000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

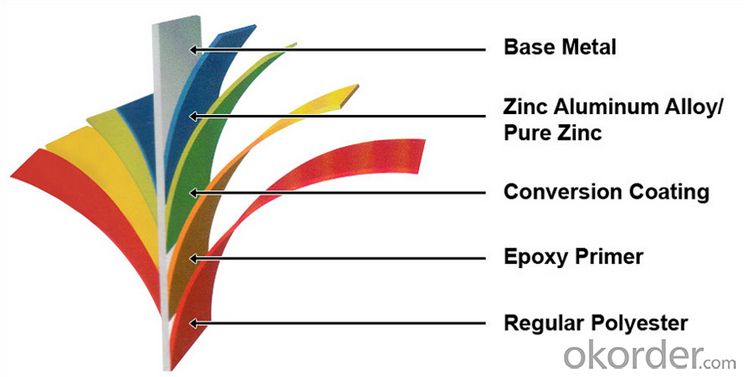

Structure of BMP Z21 PPGI Rolled Steel Coil for Roofing Constrution

Description of BMP Z21 PPGI Rolled Steel Coil for Roofing Constrution

Cold rolled steel coil is steel that has been worked below its recrystallization temperature by passing it between a pair of rollers. Recrystallization temperature is the temperature at which grains in the lattice structure of the metal have been rearranged, leaving it free of strain and deformations. Cold rolled steel coil is pre-treated before being cold rolled with a process known as pickling, which uses strong acids to remove scale and other impurities. The cold rolled steel coil is then passed through rollers to reduce its thickness. Most cold rolling takes place in multiple passes and as the size of the cold rolled steel coil is further reduced, its strength and hardness both increase, but its ductility decreases. After cold rolling, heating the metal up in a process known as annealing can restore some of its ductility. The final cold rolled steel coil may be manufactured in the form of sheets, strips, bars, or other forms.

Main Feature of BMP Z21 PPGI Rolled Steel Coil for Roofing Constrution

The construction industry: The roof structure, keel, grill, Clapboard, ceilings, fire shutter doors, etc; The light industry, the Automobile, agriculture, animal husbandry, fishery, casing of household Electronic application, civilian smoke stack, etc.

Applications of BMP Z21 PPGI Rolled Steel Coil for Roofing Constrution

1. Base metal for coated and dipped products.

2. Home appliance

3. Precise welding tube

4. Flux cored welding wire

5. Bicycle, battery shell,

6. Automobile fitting, hardware

7. Enameling industry etc.

Specifications of BMP Z21 PPGI Rolled Steel Coil for Roofing Constrution

Standard | ASTM A653, JIS G3302, GB/T3830-2006 |

Grade | SGCC, DX51D, A653, SGCH, Q235B |

Thickness | 0.125-1.0mm |

Width | 600-1250mm |

Base metal | Galvanized steel coils, Alumzinc steel coils, color coated steel coils |

Zinc coating | 40-275g/M2 |

Coil ID | 508mm/610mm |

Packing | Standard seaworthy export packing: 3 layers of packing, inside is kraft paper, water plastic film is in the middle and outside GI steel sheet to be covered by steel strips with lock, with inner coil sleeve. |

Delivery | Within 10-30days after signing contract |

Price | FOB& CNF& CIF price |

Payment terms | TT or LC, Western Union |

Capacity | 1000MT per month |

MOQ | 25MT/20GP |

Usage | construction, the manufacturing of cars, ships, containers and household electric appliances,other industries usage. |

FAQ of BMP Z21 PPGI Rolled Steel Coil for Roofing Constrution

We have organized several common questions for our clients,may help you sincerely:

1.Do you have QC teams?

Yeah, sure, our QC team is very important, they will keep the quality control for our products.

2.Are the products tested before shipping?

Yes, all of our PPGI and GI was qualified before shipping. We test every batch every day.

3.What's your normal delivery time?

Our delivery time about 15-20days for standard sizes, if you have other requirements like hardness, quanity and width ,it is about 20-40days. But don't worry ,we also try our best for the delivery time ,because time longer and our cost is higher.

- Q: What are the different types of steel surface treatments for coils?

- There are several types of steel surface treatments for coils, including hot-dip galvanizing, electro-galvanizing, galvannealing, and organic coating. Hot-dip galvanizing involves immersing the steel coil in a bath of molten zinc to create a protective layer. Electro-galvanizing applies a thin layer of zinc to the surface using an electrical current. Galvannealing is a process that combines galvanizing and annealing to create a zinc-iron alloy layer. Organic coating involves applying a protective layer of paint or other organic material to the steel surface.

- Q: Can steel coils be welded?

- Yes, steel coils can be welded. Welding is a common method used to join steel coils together, whether for manufacturing purposes or repair work.

- Q: Which one has more electrical resistivity? Wood or steel? And why?I know that the resistivity depends on the material of the conductor, but i want a perfect explaination please.Thnx in advance :)

- Wood is made up of elements which are non-metals with a high electron affinity. Specifically, carbon, oxygen, hydrogen, and some nitrogen. Furthermore the covalent bond structure in wood means electrons are tightly bound and cannot move easily from atom to another. Not without adding a great deal of energy to the first. Steel is mostly iron, which is a metal. Metals have low electron affinity. The outer electrons in metals are bound very loosely, so that they can move from atom to atom using almost no energy. Metals tend to conduct electricity very easily.

- Q: What are the common defects in steel coil surface finishes?

- Common defects in steel coil surface finishes include scratches, pits, roll marks, stains, and unevenness. These defects can be caused by various factors such as improper handling, processing issues, or equipment malfunction. These surface defects affect the aesthetics and quality of the steel coil, making it unsuitable for certain applications or requiring additional processing to rectify the defects.

- Q: I have two theories, which one's correct?My book says that steel is made up of 98% iron and 2% carbon.98% of iron's molar mass (55.85 g/mol) is 54.733.2% of carbon's molar mass (12.01 g/mol) is .2402.If you add them up that gives you that steel has a molar mass of 54.97 g/mol.However, steel's chemical formula is Fe(3)CThat would make it's molar mass 179.56 g/mol.( Because 3(55.85) + 12.01 = 179.56 )Which one is correct?

- Molar Mass Steel

- Q: How are steel coils used in the manufacturing of roofing materials?

- Steel coils are used in the manufacturing of roofing materials by being processed and shaped into various forms such as sheets, shingles, or panels. These coils are typically coated with protective layers to enhance durability and resistance to corrosion. The coils are then cut, formed, and assembled to create the final roofing product, ensuring strength, reliability, and longevity for the roofs.

- Q: What are the dimensions of steel coils used in the energy sector?

- The dimensions of steel coils used in the energy sector vary depending on the specific application and requirements. However, common dimensions range from 0.3 to 3 millimeters in thickness and 600 to 2000 millimeters in width. The inner diameter of the coil typically ranges from 508 to 610 millimeters, while the outer diameter can vary from 1000 to 2000 millimeters. It's important to note that these dimensions can be customized to suit different needs and specifications.

- Q: Can steel coils be coated with ceramic?

- Yes, steel coils can be coated with ceramic. This coating provides several benefits such as increased corrosion resistance, improved heat resistance, and enhanced durability. Additionally, ceramic coating can also provide an aesthetic appeal to the steel coils.

- Q: How are steel coils used in the manufacturing of automotive components?

- Steel coils are used in the manufacturing of automotive components as they serve as the primary raw material for producing various parts such as car bodies, chassis, and engine components. The coils are processed through a series of manufacturing techniques, including cutting, shaping, and welding, to transform them into specific automotive components. The high strength and durability of steel make it an ideal choice for these applications, ensuring the structural integrity and safety of the final automotive products.

- Q: Steel being my favorite type, I just picked up Heart Gold today, my gf got Soul Silver...I was wondering which steel types are available and somewhat easily obtainable in HG (and/or what is the earliest steel type I can get?)

- for me would be steelex but u have to get onix and get him to level fifty and trade with a friend and he will evolve into steelex as long as your friend gives it back to you lol

Send your message to us

BMP Z21 PPGI Rolled Steel Coil for Roofing Constrution

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m.t.

- Supply Capability:

- 30000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords