BMP Z28 PPGI Rolled Steel Coil for Roofing Constrution

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m.t.

- Supply Capability:

- 30000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

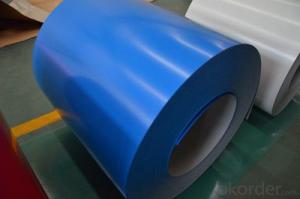

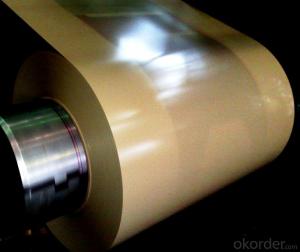

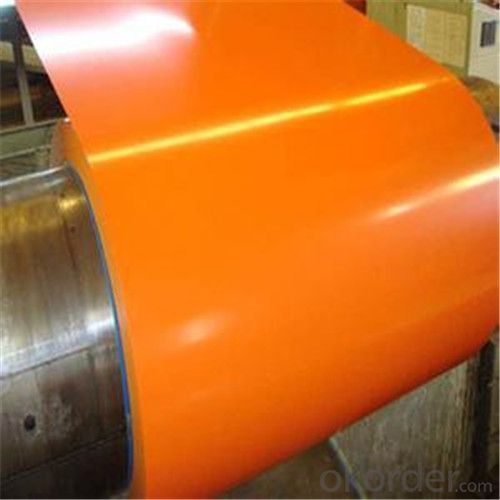

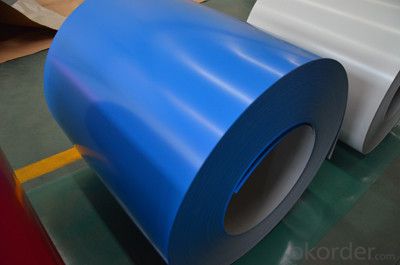

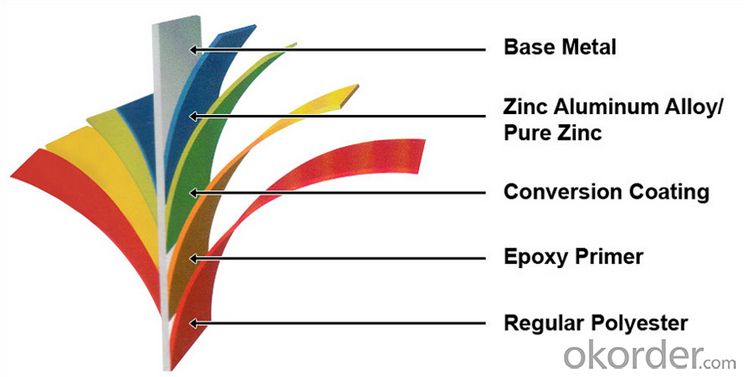

Structure of BMP Z28 PPGI Rolled Steel Coil for Roofing Constrution

Description of BMP Z28 PPGI Rolled Steel Coil for Roofing Constrution

Prepainted galvanized steel coil, PPGI, PPGL, Prepainted galvalume/aluzincsteel, Color Coated Galvalume Steel Coil, Prepainted Galvalume Steel Coils, RAL color, 0.15-1.5mm, SGCC, CGCC, CGLC, DX51D, TDC51D, ASTM A653, CS TYPE, S280GO, S350GD, G550, JIS G3312, EN 10169 JIS G3322, ASTM A755/755M, comercial and structual quality

Main Feature of BMP Z21 PPGI Rolled Steel Coil for Roofing Constrution

The construction industry: The roof structure, keel, grill, Clapboard, ceilings, fire shutter doors, etc; The light industry, the Automobile, agriculture, animal husbandry, fishery, casing of household Electronic application, civilian smoke stack, etc.

Applications of BMP Z28 PPGI Rolled Steel Coil for Roofing Constrution

it is ideal for a wide range of applications,, such as pre-engineered buildings, architectural panels, roofing, siding, cladding, and many other building components.and also used back plate of appliance; wide range of construction, furniture industry, transportation industry, etc.

Exterior decoration of buildings: Roof and wallboards of industrial, commercial, residential and public facilities

Interior decoration of buildings: Wallboards, ceiling boards, partition boards, fireproof doors

Building accessories: Window panels, signboards

Home appliances: Oil/gas boilers, rice buckets, portable gas burners, etc.

Specifications of BMP Z28 PPGI Rolled Steel Coil for Roofing Constrution

Standard | ASTM A653, JIS G3302, GB/T3830-2006 |

Grade | SGCC, DX51D, A653, SGCH, Q235B |

Thickness | 0.125-1.0mm |

Width | 600-1250mm |

Base metal | Galvanized steel coils, Alumzinc steel coils, color coated steel coils |

Zinc coating | 40-275g/M2 |

Coil ID | 508mm/610mm |

Packing | Standard seaworthy export packing: 3 layers of packing, inside is kraft paper, water plastic film is in the middle and outside GI steel sheet to be covered by steel strips with lock, with inner coil sleeve. |

Delivery | Within 10-30days after signing contract |

Price | FOB& CNF& CIF price |

Payment terms | TT or LC, Western Union |

Capacity | 1000MT per month |

MOQ | 25MT/20GP |

Usage | construction, the manufacturing of cars, ships, containers and household electric appliances,other industries usage. |

FAQ of BMP Z28 PPGI Rolled Steel Coil for Roofing Constrution

We have organized several common questions for our clients,may help you sincerely:

1.Do you have QC teams?

Yeah, sure, our QC team is very important, they will keep the quality control for our products.

2.Are the products tested before shipping?

Yes, all of our PPGI and GI was qualified before shipping. We test every batch every day.

3.What's your normal delivery time?

Our delivery time about 15-20days for standard sizes, if you have other requirements like hardness, quanity and width ,it is about 20-40days. But don't worry ,we also try our best for the delivery time ,because time longer and our cost is higher.

- Q: How do steel coils contribute to the manufacturing of agricultural machinery?

- Steel coils play a crucial role in the manufacturing of agricultural machinery. These coils are typically made from high-quality steel, which possesses excellent strength, durability, and resistance to corrosion. Firstly, steel coils are used in the fabrication of the main structural components of agricultural machinery, such as the chassis, frames, and supports. These components need to withstand heavy loads, extreme weather conditions, and rough terrains. The strength and resilience of steel coils ensure that the machinery can handle these demanding environments and perform efficiently. Moreover, steel coils are utilized in the production of various moving parts and mechanisms within agricultural machinery. For instance, they are used to create gears, shafts, and axles, which are essential for transmitting power and transforming rotational motion. Steel's high tensile strength and excellent machinability make it an ideal material for these critical components, ensuring their reliability and longevity. Steel coils also contribute to the production of agricultural machinery by providing a protective layer against wear and tear. The coils are often coated with specialized finishes or paints to enhance their resistance to rust, chemicals, and abrasion. This protective layer extends the lifespan of the machinery and reduces the need for frequent maintenance and repairs, ultimately increasing its overall efficiency and productivity. Furthermore, the versatility of steel coils allows for customization and adaptation to meet the specific requirements of agricultural machinery. Manufacturers can shape and form the coils into various sizes and dimensions, enabling the production of machinery suitable for different farming practices and applications. Whether it's tractors, harvesters, or irrigation systems, steel coils are essential in creating versatile and reliable agricultural machinery. In summary, steel coils are indispensable in the manufacturing of agricultural machinery due to their strength, durability, resistance to corrosion, and customization capabilities. From structural components to moving parts and protective coatings, steel coils contribute significantly to the efficiency, reliability, and longevity of agricultural machinery, ultimately supporting the global agricultural industry.

- Q: How are steel coils used in the production of metal partitions?

- The production of metal partitions relies heavily on steel coils, which are a vital ingredient. These coils, typically made from top-notch steel, act as the primary material for manufacturing the partitions. To begin with, the steel coils undergo a process called slitting, where they are sliced into narrower strips of the desired width. This step allows manufacturers to tailor the size of the metal partitions according to specific project requirements. Following slitting, the steel strips are fed into a roll forming machine. This machine gradually transforms the strips into the desired profile for the metal partitions. The roll forming process involves passing the steel strips through a series of rollers, which progressively bend and shape the metal into the desired form and dimensions. Once the metal has been shaped as desired, it is then cut into appropriate lengths to create individual partitions. These partitions undergo further processing, such as welding or spot welding, to join different components and enhance their structural integrity. Steel coils are highly preferred for metal partition production due to their strength, durability, and versatility. The use of steel ensures that the partitions can withstand heavy loads, resist corrosion, and offer long-lasting performance. Moreover, steel coils provide a high degree of design flexibility, allowing for the creation of various partition styles, including solid panels, perforated screens, or mesh partitions. All in all, steel coils play a pivotal role in the production of metal partitions by providing the necessary raw material, strength, and customization options required for these adaptable architectural elements.

- Q: I am looking for a steel taper kit to help me start stretching my earlobes. I wanted something like the following but in steel instead of acrylic. Preferably something under $40 and from a reputable website. I don't know how much damage acrylic tapers can do in the few seconds it would be inside my earlobe, but I would rather use steel just to be safe. I will be forever grateful if anyone can help.

- www.okorder

- Q: PLEASE PLEASE PLEASE!!!!!!!! HELP MEEEEEEEE!!!!!!! I need to know how can i prevent steel from rusting when it is exposed to water or salt water or vinegar. PLEASE TELL ME A LOT OF WAYS THAT I COULD PREVENT IT!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!

- rust is oxidation . remove contact with O2 , it wont rust . you can place it in a oxygen free atmosphere , you could plate it with zinc or chrome , you can use a lead based paint .

- Q: I had heard of steel braided fuel lines but ive also seen some air and coolant lines that are steel braided. Are these commonly used? I guess what I'm asking is if its a good idea to use them.

- Steel braided line are mainly use in turbulence areas, where they need to be protected. i would recommend replacing your brake line with it but not your coolant or air lines. there are other materials that are well suitable for coolant and air lines.

- Q: What are the different methods of embossing steel coils?

- There are numerous techniques for embossing steel coils, each possessing unique characteristics and applications. Some of the most prevalent techniques include: 1. Hot embossing: By heating the steel coil to a high temperature and pressing it between two engraved rollers, this method allows for intricate designs or textures to be imprinted onto the surface. The heat softens the steel, facilitating the desired pattern transfer. 2. Cold embossing: In contrast to hot embossing, cold embossing does not require heating the steel coil. Instead, it employs pressure and specifically designed dies or stamps to produce the desired pattern. Cold embossing is commonly used for simpler designs or when working with heat-sensitive materials. 3. Roller embossing: This technique involves using a series of rollers with engraved patterns to imprint the design onto the steel coil. The coil is passed through the rollers, and the applied pressure transfers the pattern onto the surface. Roller embossing is often utilized for larger-scale production, delivering consistent and uniform results. 4. Laser embossing: A modern method that employs laser technology to create patterns on steel coils. The laser beam selectively melts or vaporizes the metal, generating the desired design. Laser embossing offers high precision and flexibility, making it suitable for intricate and detailed patterns. 5. Press embossing: This technique utilizes a press machine equipped with custom-made dies to imprint the desired pattern onto the steel coil. The coil is positioned between the dies, and the press machine applies pressure, transferring the pattern onto the surface. Press embossing is commonly used for large-scale production, achieving high-speed and high-volume embossing. Ultimately, the choice of embossing method depends on various factors, including design complexity, production volume, material properties, and cost considerations. Each technique possesses advantages and limitations, necessitating careful selection by manufacturers based on their specific requirements.

- Q: What are the common industry standards for steel coils?

- The common industry standards for steel coils vary depending on the region and specific application. However, there are several widely recognized standards that are commonly used in the steel industry. One of the most commonly referenced standards for steel coils is the American Society for Testing and Materials (ASTM) standard. ASTM has developed a wide range of specifications for different types of steel coils, such as hot-rolled, cold-rolled, and galvanized coils. These specifications outline various mechanical and chemical properties that the steel must meet, as well as dimensions, tolerances, and testing requirements. In addition to ASTM, other international organizations such as the International Organization for Standardization (ISO) and the European Committee for Standardization (EN) have also established standards for steel coils. ISO standards, such as ISO 3574 and ISO 5952, provide guidelines for the general requirements, dimensional tolerances, and mechanical properties of steel coils. Similarly, EN standards, such as EN 10130 and EN 10131, specify the characteristics and tolerances for cold-rolled steel coils. Furthermore, industry-specific organizations and associations may have their own standards for steel coils. For example, the American Iron and Steel Institute (AISI) has developed specific standards for different types of steel products, including coils. These standards cover various aspects such as chemical composition, mechanical properties, and surface finish. It is important to note that steel coil standards can also be determined by the end-use application. Industries such as automotive, construction, and manufacturing may have specific requirements that go beyond the general standards. In such cases, customers and manufacturers may refer to industry-specific standards or work together to define custom specifications. Overall, while there are several common industry standards for steel coils, it is crucial to consult the specific standards and requirements applicable to the region and application in question to ensure compliance and quality.

- Q: How do steel coils contribute to the agricultural industry?

- The agricultural industry relies heavily on steel coils as a crucial component for the production and maintenance of various agricultural machinery and equipment. These coils are primarily used to manufacture farm equipment like tractors, plows, harvesters, and irrigation systems. One of the key benefits of steel coils is their durability and strength, which makes them ideal for agricultural applications. These coils are processed and shaped into different sizes to create robust components that can withstand the demanding conditions and heavy workloads typically associated with farming operations. Steel coils are widely used in constructing tractor frames, ensuring the vehicles' structural integrity and stability. They are also utilized in manufacturing plow blades, providing the necessary strength to effectively cut through the soil and prepare the land for planting. Moreover, steel coils are crucial in creating harvester blades, which enable efficient harvesting and minimize crop damage. In addition to machinery, steel coils play a vital role in the production of irrigation systems, which are essential for agricultural practices. These systems require pipes and tubes that can endure high water pressures and resist corrosion caused by the elements. Steel coils are processed into these pipes and tubes, ensuring their durability and longevity, and thereby facilitating efficient water management and irrigation in fields. Furthermore, steel coils contribute to the agricultural industry by ensuring the secure storage and transportation of agricultural products. They are used in constructing storage silos and grain bins, which provide safe and weather-resistant spaces for storing crops. Steel coils are also utilized in fabricating transportation containers like trailers and trucks, ensuring the safe delivery of agricultural goods from farms to markets. In summary, steel coils have a significant impact on the agricultural industry. Their strength, durability, and versatility make them essential for manufacturing agricultural machinery, irrigation systems, storage facilities, and transportation containers. By providing reliable and efficient equipment, steel coils contribute to increased productivity, improved crop yields, and enhanced overall efficiency in the agricultural sector.

- Q: steel can be used to do?

- Stainless steel can be used to (1) industrial use stainless steel (2) building decoration use stainless steel;(3) medical equipment (4) life with stainless steel tableware and the Jawaysteel is a great Chinese company, offer various kinds of stainless steel Maybe you can to their advice

- Q: How are steel coils used in the manufacturing of electrical enclosures?

- Steel coils are used in the manufacturing of electrical enclosures as they provide the raw material for forming the enclosures' outer shells and structural components. The steel coils are processed and shaped through various techniques such as cutting, bending, and welding, to create the desired size and shape of the enclosure. The steel's strength and durability make it an ideal material choice for ensuring the enclosures can protect electrical equipment from environmental factors and provide safety for users.

Send your message to us

BMP Z28 PPGI Rolled Steel Coil for Roofing Constrution

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m.t.

- Supply Capability:

- 30000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords