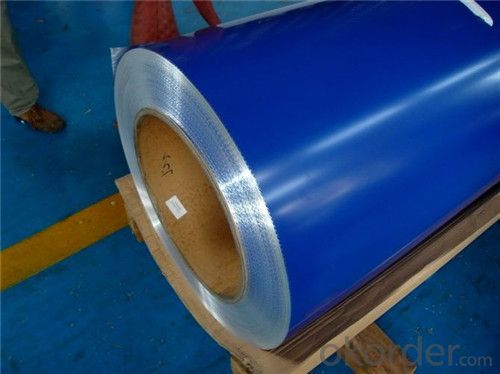

BMP Z30 PPGI Rolled Steel Coil for Construction Roofing

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m.t.

- Supply Capability:

- 30000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

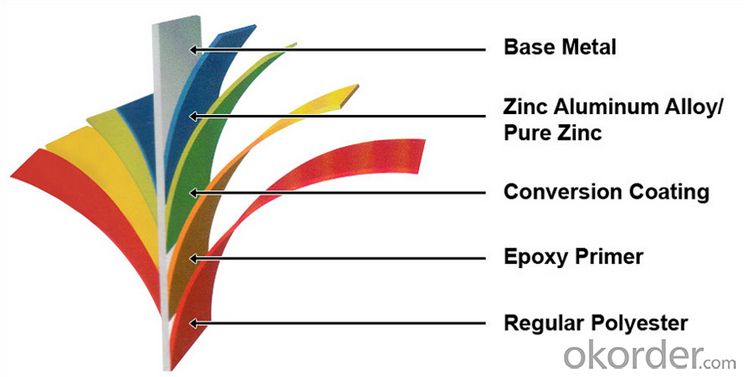

Structure of BMP Z30 PPGI Rolled Steel Coil for Construction Roofing

Description of BMP Z30 PPGI Rolled Steel Coil for Construction Roofing

PPGI is made by cold rolled steel sheet and galvanized steel sheets as baseplate, through the surface pretreatment (degreasing, cleaning, chemical conversion processing), coated by the method of continuous coatings (roller coating method), and after roasting and cooling.

Main Feature of BMP Z30 PPGI Rolled Steel Coil for Construction Roofing

1. Resistance to Corrosion Has better performance in corrosion resistance than hot dip galvanized coil/sheet of the same thickness and its service life is 1-5 times longer than general hot dip galvanized coil/sheet.

2. Machinability Can satisfy the processing requirements of rolling, coiling and others processes alike.

3. Thermal Resistance Can sustain the environment at 315Centigrade for long time.

4. High Reflectivity Reflection ability of heat and light is twice as much as those of hot dip galvanized steel coil/sheet, and its reflectivity is more than 0.75, exceeding 0.65 (required by the EPA Energy Star Standard), which is an ideal construction material of saving energy.

Applications of BMP Z35 PPGI Rolled Steel Coil for Construction Roofing

A. Corrugated design makes it excellent waterproof performance

B. Materials as prepainted steel sheets, galvanized steel sheets, galvalume (Al-Zn coated sheets) are available to make corrugated sheet.

C.Those material are durable, anti-corrosion in bad weather for 20-30 years based on it's Zinc(Galvanized) coating or AZ (Galvalume) coating.

D. Different shape of the sheet make it suitable for any style of buildings.

E.Easy to install, no need special tools to fix the sheet.

F.Light weight due to high strength to weight ratio of steel. Light weight means easier handling lower shipping costs, easier installation

G. Different color is availbe base on the RAL Standard make your building more beautiful.

H. We will provide the best solutions if you don't have a exact idea of the specification you want for the steel sheet based on your weather conditions, engineering structure, construction budget and so on.

Specifications of BMP Z30 PPGI Rolled Steel Coil for Construction Roofing

Standard | ASTM A653, JIS G3302, GB/T3830-2006 |

Grade | SGCC, DX51D, A653, SGCH, Q235B |

Thickness | 0.125-1.0mm |

Width | 600-1250mm |

Base metal | Galvanized steel coils, Alumzinc steel coils, color coated steel coils |

Zinc coating | 40-275g/M2 |

Coil ID | 508mm/610mm |

Packing | Standard seaworthy export packing: 3 layers of packing, inside is kraft paper, water plastic film is in the middle and outside GI steel sheet to be covered by steel strips with lock, with inner coil sleeve. |

Delivery | Within 10-30days after signing contract |

Price | FOB& CNF& CIF price |

Payment terms | TT or LC, Western Union |

Capacity | 1000MT per month |

MOQ | 100MT |

Usage | construction,the manufacturing of cars, ships, containers and household electric appliances,other industries usage. |

FAQ of BMP BMP Z30 PPGI Rolled Steel Coil for Construction Roofing

We have organized several common questions for our clients,may help you sincerely:

1.What is your package:

Sea worthy Export Packing Standard export and seaworthy packing. (waterproof paper and metal sheet protection with fluted rings at inner and outer edges, 4 eye bands and 4 circumferential bands fasten the coil)

2.Are the products tested before shipping??

Yes, all of our PPGI and GI was qualified before shipping. We test every batch every day.

3.What's your normal delivery time?

Our delivery time about 15-20days for standard sizes, if you have other requirements like hardness, quanity and width ,it is about 20-40days. But don't worry ,we also try our best for the delivery time ,because time longer and our cost is higher.

- Q: What are the different methods of punching steel coils?

- There are several methods of punching steel coils, including mechanical punching, hydraulic punching, and laser punching. Mechanical punching involves the use of a mechanical press with a punch and die set to create holes or shapes in the steel coil. Hydraulic punching utilizes hydraulic force to drive a punch through the coil, providing high precision and speed. Laser punching, on the other hand, uses a laser beam to cut or form holes in the steel coil, offering great flexibility and accuracy. Each method has its own advantages and suitability depending on the specific requirements of the application.

- Q: Molten steel changes to solid steel at its __________ point. Could you please fill in the blank? Thank you so much, it is greatly appreciated. I have been looking for the answer to this question for a long time, but I never understand what the websites are trying to say because I don't have that big of a vocabulary and don't know what they mean. I've seen things saying steel boiling point, steel melting point, and steel freezing point. I don't know what any of those mean, and they might be the answer. Please help me. Thank you.

- just like a melting point of ice and the boiling point of water, there are different points where something is converted into another form. such as icewatersteam. it's always the same thing and it's a physical change, but just in a different form. molten steel changes to solid steel at it's freezing point. or solid point. i'm not sure how you would word that. but it would not be melting or boiling point. hope that helped.

- Q: How are steel coils used in the production of infrastructure materials?

- The durability, versatility, and strength of steel coils make them widely used in the production of infrastructure materials. Typically, these coils are made from hot-rolled steel, forming large rolls or coils that are easily transported and handled. One common application of steel coils in infrastructure materials involves producing steel sheets and plates. These coils can be further processed to create flat sheets of steel, which are then utilized in various construction purposes. For instance, steel sheets are frequently employed in manufacturing bridges, highways, and buildings due to their ability to withstand heavy loads and adverse weather conditions. Another important use of steel coils in infrastructure materials is manufacturing pipes and tubes. Steel coils are often processed into seamless or welded pipes that find usage in water and gas pipelines, as well as the transportation of liquids and gases. Infrastructure projects prefer steel pipes and tubes due to their high strength, corrosion resistance, and ability to endure high-pressure environments. Moreover, steel coils are also employed in the production of reinforcing bars or rebars, crucial components in the construction of reinforced concrete structures. These rebars, made from coiled steel, are embedded within concrete to provide tensile strength and enhance the structural integrity of buildings, bridges, and other infrastructure projects. Steel coils enable efficient production of rebars, ensuring consistent quality and size for reinforced concrete constructions. In conclusion, the use of steel coils is essential in the production of infrastructure materials. Their contribution to manufacturing steel sheets, pipes, and rebars ensures the durability, strength, and reliability of infrastructure projects. By providing a versatile and robust material, steel coils contribute to the development of safe and long-lasting structures in our built environment.

- Q: I have several stainless steel utensils and appliances, so when I put them through the dishwasher some of them are rusting, I think its because my current dishwashing soap is harsh, what is some great dishwashing soap that will clean my dishes and not be so hard on my stainless steel appliances and utensils?

- Jan is correct. You need to have some nickel in the stainless steel to prevent rusting, like 18/10 which has 10% nickel alloy in the steel.

- Q: They are showing on tv a special on how the new World Trade Center, building 1, is being built. Focusing on the steel and the guys fitting everything together.Where do builders go to buy all that steel framing? We do not build really tall buildings where I live so most of the steel is cut and welded on the job site. At World Trade Center 1, they seem to get the steel on trucks; already cut and welded.

- The steel is all custom fabricated in what are called structural steel fabrication shops. Each Building is designed by architects then the frame is designed by engineers to support whatever load is being applied to the building. After the engineering is done it goes out for a bid package where a fab shop estimates how much to charge for the fabrication of the steel and the erection of the steel. Once a company wins the bid, it then has to design how the steel will connect with one another and have it approved by an engineering firm to assure the connections are strong enough. Once all of that happens the fab shop orders raw steel beams and angle iron and steel plate at stock lengths. Beams are then cut into the right length and holes drilled in the proper places. The beam is then marked with a number that tells the erectors where it goes. The steel is then shipped out in batches to the construction site where it is unloaded and shook out into an organized place to grab them with a crane. They are then put together like a toy model, there are instructions that say what beam goes where and what size bolt to use. The welding you see being done is on really critical moments that need extra strength. That is about how it goes in a nutshell. It is a bit more complicated than that but it gives you an idea.

- Q: How are steel coils used in the production of industrial equipment?

- Steel coils are a vital component in the production of industrial equipment. These coils are large, flat rolled sheets of steel that are typically used as raw material in various manufacturing processes. Firstly, steel coils are used for fabrication purposes, where they are cut, shaped, and welded together to create the framework or structure of industrial equipment. This includes machinery, heavy-duty vehicles, storage tanks, and other industrial components. The coils provide the necessary strength and durability to withstand the demanding conditions faced by industrial equipment. Additionally, steel coils are often formed into specific shapes to produce parts and components for industrial machinery. These parts can include gears, shafts, bearings, brackets, and many others. The versatility of steel allows it to be easily manipulated and fabricated into different shapes and sizes, making it an ideal material for such applications. Moreover, steel coils are also used in the construction of industrial equipment, particularly in the manufacturing of boilers, heat exchangers, and pressure vessels. These coils are typically formed into tubes or pipes, which are then welded or brazed together to create the necessary structure for these equipment. The high strength and heat resistance properties of steel make it the preferred material for such applications, ensuring the safe and efficient operation of industrial processes. In summary, steel coils play a crucial role in the production of industrial equipment. They are used as raw material for fabrication, forming parts and components, and constructing crucial equipment such as boilers and pressure vessels. The durability, strength, and versatility of steel make it an indispensable material in the manufacturing industry.

- Q: What are the different methods of surface inspection for steel coils?

- Some of the different methods of surface inspection for steel coils include visual inspection, magnetic particle inspection, dye penetrant inspection, eddy current inspection, and ultrasonic inspection.

- Q: I mean 4 inch thick steel like was used in the WTC buildings, especially WTC 7 which did not get hit by a plane. Can carpeting, desk chairs, water coolers and dry erase boards burn hot enough and long enough to melt steel that is normally made in a blast furnace?

- they shouldn't, provided that they are properly fireproofed. in the case of the wtc the explosion of the plane instantaneously removed the spray on fireproofing in the members. the unprotected members then melted. had the fireproofing remained on the members the office equipment etc most likely would have burnt itself out before the members became comprimised.

- Q: what is the difference between metal and steel

- well, steel is a type of metal. It's sort of like asking the difference between a bug and an ant, an ant is a bug, but not every bug is an ant. Likewise, steel is metal, but not all metal is steel. Gold is metal, Silver is metal, Iron is metal, Steel is metal.

- Q: Can steel coils be coated with thermally insulating materials?

- Yes, steel coils can be coated with thermally insulating materials.

Send your message to us

BMP Z30 PPGI Rolled Steel Coil for Construction Roofing

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m.t.

- Supply Capability:

- 30000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords