BMP Z15 PPGI Rolled Steel Coil for Roofing Constrution

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m.t.

- Supply Capability:

- 30000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Structure of BMP Z15 PPGI Rolled Steel Coil for Roofing Constrution

Description of BMP Z15 PPGI Rolled Steel Coil for Roofing Constrution

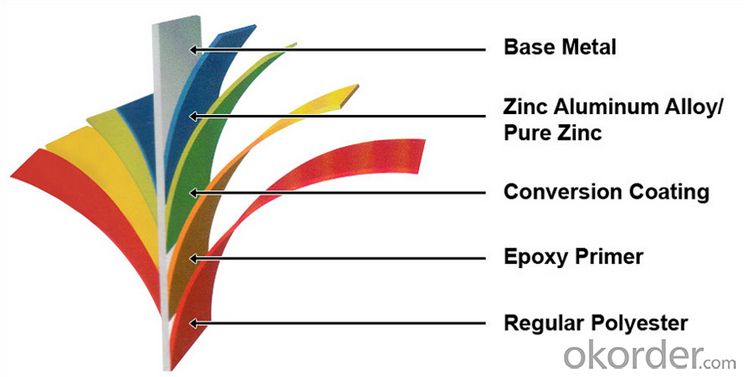

Galvanized sheet or coil is defined as a carbon steel sheet coated with zinc on both sides. Continuous hot dipping, or electro-galvanizing are the two processes used to produce galvanized sheet and coil. Generally speaking, the hot dip process consists of passing the steel through a bath of molten zinc. The electro galvanizing process consists of the application of zinc by electrolytic disposition.The result is a layer of zinc tightly adhering to the base metal through an iron-zinc bonding layer.

Main Feature of BMP Z15 PPGI Rolled Steel Coil for Roofing Constrution

1. Resistance to Corrosion Has better performance in corrosion resistance than hot dip galvanized coil/sheet of the same thickness and its service life is 1-5 times longer than general hot dip galvanized coil/sheet.

2. Machinability Can satisfy the processing requirements of rolling, coiling and others processes alike.

3. Thermal Resistance Can sustain the environment at 315Centigrade for long time.

4. High Reflectivity Reflection ability of heat and light is twice as much as those of hot dip galvanized steel coil/sheet, and its reflectivity is more than 0.75, exceeding 0.65 (required by the EPA Energy Star Standard), which is an ideal construction material of saving energy.

Applications of BMP Z15 PPGI Rolled Steel Coil for Roofing Constrution

A. Corrugated design makes it excellent waterproof performance

B. Materials as prepainted steel sheets, galvanized steel sheets, galvalume (Al-Zn coated sheets) are available to make corrugated sheet.

C.Those material are durable, anti-corrosion in bad weather for 20-30 years based on it's Zinc(Galvanized) coating or AZ (Galvalume) coating.

D. Different shape of the sheet make it suitable for any style of buildings.

E.Easy to install, no need special tools to fix the sheet.

F.Light weight due to high strength to weight ratio of steel. Light weight means easier handling lower shipping costs, easier installation

G. Different color is availbe base on the RAL Standard make your building more beautiful.

H. We will provide the best solutions if you don't have a exact idea of the specification you want for the steel sheet based on your weather conditions, engineering structure, construction budget and so on.

Specifications of BMP Z15 PPGI Rolled Steel Coil for Roofing Constrution

Standard | ASTM A653, JIS G3302, GB/T3830-2006 |

Grade | SGCC, DX51D, A653, SGCH, Q235B |

Thickness | 0.125-1.0mm |

Width | 600-1250mm |

Base metal | Galvanized steel coils, Alumzinc steel coils, color coated steel coils |

Zinc coating | 40-275g/M2 |

Coil ID | 508mm/610mm |

Packing | Standard seaworthy export packing: 3 layers of packing, inside is kraft paper, water plastic film is in the middle and outside GI steel sheet to be covered by steel strips with lock, with inner coil sleeve. |

Delivery | Within 10-30days after signing contract |

Price | FOB& CNF& CIF price |

Payment terms | TT or LC, Western Union |

Capacity | 1000MT per month |

MOQ | 25MT/20GP |

Usage | construction, the manufacturing cars, ships,containers household electric appliances, other industries usage. |

FAQ of BMP Z15 PPGI Rolled Steel Coil for Roofing Constrution

We have organized several common questions for our clients,may help you sincerely:

1.Are you a factory or a trading company?

CNBM is a trading company in this industry over 30 years, located in Beijing

2.What's your MOQ?

25MT, it is for one container.

3.Do you have QC teams?

Yeah, sure, our QC team is very important, they will keep the quality control for our products.

4.Are the products tested before shipping?

Yes, all of our PPGI and GI was qualified before shipping. We test every batch every day.

5.What's your normal delivery time?

Our delivery time about 15-20days for standard sizes, if you have other requirements like hardness, quanity and width ,it is about 20-40days. But don't worry ,we also try our best for the delivery time ,because time longer and our cost is higher.

- Q: How do steel coils impact the environment?

- Steel coils can have significant environmental impacts throughout their lifecycle. The production of steel coils involves extracting and processing raw materials, which can result in deforestation, habitat destruction, and air and water pollution. Additionally, the energy-intensive manufacturing process contributes to greenhouse gas emissions. Improper disposal or recycling of steel coils can further exacerbate environmental harm. Overall, the environmental impact of steel coils underscores the need for sustainable production practices and responsible end-of-life management.

- Q: What are the different types of steel processing techniques for coils?

- There are several types of steel processing techniques for coils, including hot rolling, cold rolling, annealing, pickling, and galvanizing.

- Q: Can steel coils be reused?

- Yes, steel coils can be reused. They are often recycled and used in various industries such as automotive, construction, and manufacturing. The coils can be melted down and reshaped into new products, reducing the need for new raw materials and promoting sustainability.

- Q: What are the different types of steel coil slitting methods?

- There are three main types of steel coil slitting methods: rotary slitting, loop slitting, and pull-through slitting. Rotary slitting involves using circular knives to cut the coil into narrower strips. Loop slitting involves passing the coil through a loop that is formed between two sets of knives, which then cuts the coil into multiple strips. Pull-through slitting involves pulling the coil through an adjustable slitting head, where the knives cut the coil into desired widths.

- Q: I have several stainless steel utensils and appliances, so when I put them through the dishwasher some of them are rusting, I think its because my current dishwashing soap is harsh, what is some great dishwashing soap that will clean my dishes and not be so hard on my stainless steel appliances and utensils?

- Stainless steel that has screws almost always rusts in the dishwasher. Also semi-complicated stainless steel utensils rust in the dishwasher...things like an egg whisker. This is true no matter what detergent you use. Dishwasher detergent almost always contains bleach. That causes stainless to rust if it has nooks and crannies. The solution? Hand wash them and let them air dry. The only stainless steel I run through the dishwasher is table flatware (knives, spoons, and forks.) You'll get a much longer life out of your utensils if you hand wash them and just let them air dry.

- Q: What are the different methods of galvanizing steel coils?

- There are several methods of galvanizing steel coils, including hot-dip galvanizing, electro-galvanizing, and continuous galvanizing.

- Q: I want to buy a VERY sturdy bunkbed, but don't know which one would be better with not getting loose or falling apart.

- Metal/Steel, tighten it down and put some washers in between the steel and the screw so it creates a tight fit and movement wont affect the screw directly.

- Q: I was wondering if anyone knew the grade/type of steel for this product. I'd like to use it as stock for a knife blade, but would like to know the specs so I can determine if it is suitable and, if so, how best to heat treat it.Thanks.PS: I know it isn't stainless, but that leaves a lot of other steel types.

- 1018 mild steel. Not suitable for bladesmithing. If you can't heat treat find an old file, grind it out (keep it cool) and put in an oven 400F. Modern car/truck springs are 5160 med chrome steel, a good blade quality steel and forgiving on the anvil/heat treat.

- Q: How do steel coils perform in corrosive environments?

- Steel coils typically perform well in corrosive environments due to their inherent resistance to corrosion. This is primarily because steel is an alloy composed of iron and other elements, such as carbon, which provides it with a protective layer known as a passive film. This passive film acts as a barrier between the steel surface and the corrosive elements, preventing direct contact and thus minimizing the risk of corrosion. In addition to the passive film, steel coils can also be coated with various protective coatings to enhance their resistance against corrosion. These coatings, such as zinc or epoxy, provide an additional layer of protection and further extend the lifespan of the steel coils when exposed to corrosive environments. However, it is important to note that the performance of steel coils in corrosive environments can still be influenced by factors such as the specific corrosive agent, exposure duration, and the presence of other contaminants. In highly aggressive environments, such as those with high humidity, saltwater exposure, or acidic chemicals, the protective layers on steel coils may deteriorate over time, leading to potential corrosion. To ensure optimal performance in corrosive environments, it is advisable to select steel coils with corrosion-resistant properties, such as stainless steel or galvanized steel. Regular maintenance and inspections are also crucial to identify any signs of corrosion early on and take appropriate measures to prevent further damage. Overall, steel coils offer good resistance to corrosion in most environments, but the severity of the corrosive conditions can ultimately impact their performance.

- Q: What are the different methods of coil flattening for steel coils?

- There are several methods used for coil flattening in the steel industry. Some of the common methods include roller leveling, tension leveling, and stretcher leveling. Roller leveling involves passing the coil through a series of rollers to flatten it. Tension leveling uses a combination of tension and bending to remove any shape defects in the coil. Stretcher leveling stretches the coil in the lengthwise direction to eliminate any waviness or buckling. Each method has its own advantages and is used based on the specific requirements of the steel coil.

Send your message to us

BMP Z15 PPGI Rolled Steel Coil for Roofing Constrution

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m.t.

- Supply Capability:

- 30000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords