BMP Z15 PPGI Rolled Steel Coil for Construction Roofing

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m.t.

- Supply Capability:

- 30000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

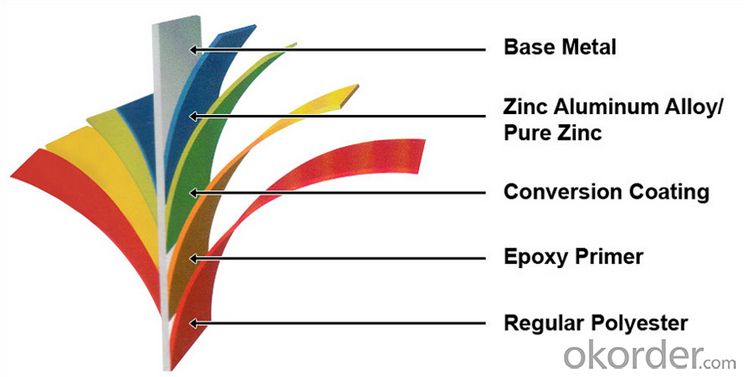

Structure of BMP Z15 PPGI Rolled Steel Coil for Construction Roofing

Description of BMP Z15 PPGI Rolled Steel Coil for Construction Roofing

Color Coated Steel Coil metal has the highest value among all cold-rolled steel products. Produced by printing or baking paints onto the surface of cold-rolled steel or GI or ALCOT sheets, pre-coated metal features a wide range of colors and patterns which are commonly used to make the exterior of buildings and consumer electronics products look more polished and sophisticated. Depending on the specific utility of each product, a vast variety of features are available including pollution resistance and anti-bacterial quality

Main Feature of BMP Z15 PPGI Rolled Steel Coil for Construction Roofing

1. Resistance to Corrosion Has better performance in corrosion resistance than hot dip galvanized coil/sheet of the same thickness and its service life is 1-5 times longer than general hot dip galvanized coil/sheet.

2. Machinability Can satisfy the processing requirements of rolling, coiling and others processes alike.

3. Thermal Resistance Can sustain the environment at 315Centigrade for long time.

4. High Reflectivity Reflection ability of heat and light is twice as much as those of hot dip galvanized steel coil/sheet, and its reflectivity is more than 0.75, exceeding 0.65 (required by the EPA Energy Star Standard), which is an ideal construction material of saving energy.

Applications of BMP Z35 PPGI Rolled Steel Coil for Construction Roofing

Exterior decoration of buildings: Roof and wallboards of industrial, commercial, residential and public facilities Interior decoration of buildings: Wallboards, ceiling boards, partition boards, fireproof doors Building accessories: Window panels, signboards Home appliances: Oil/gas boilers, rice buckets, portable gas burners, etc.

Outdoor: Roof\ Roof structure\Surface sheet of balcony\ Frame of window\Door of garage\Roller shutter door\Persian blinds\Cabana and so on.

Indoor: Door\Isolater\Frame of door\Light steel structure of house\\Folding screen\Ceiling\Internal decoration of toilet and elevator.

Building accessories: Window panels, signboards Home appliances: Oil/gas boilers, rice buckets, portable gas burners, etc.

Specifications of BMP Z15 PPGI Rolled Steel Coil for Construction Roofing

Standard | ASTM A653, JIS G3302, GB/T3830-2006 |

Grade | SGCC, DX51D, A653, SGCH, Q235B |

Thickness | 0.125-1.0mm |

Width | 600-1250mm |

Base metal | Galvanized steel coils, Alumzinc steel coils, color coated steel coils |

Zinc coating | 40-275g/M2 |

Coil ID | 508mm/610mm |

Packing | Standard seaworthy export packing: 3 layers of packing, inside is kraft paper, water plastic film is in the middle and outside GI steel sheet to be covered by steel strips with lock, with inner coil sleeve. |

Delivery | Within 10-30days after signing contract |

Price | FOB& CNF& CIF price |

Payment terms | TT or LC, Western Union |

Capacity | 1000MT per month |

MOQ | 100MT |

Usage | construction,the manufacturing of cars, ships, containers and household electric appliances,other industries usage. |

FAQ of BMP BMP Z15 PPGI Rolled Steel Coil for Construction Roofing

We have organized several common questions for our clients,may help you sincerely:

1.What is your package:

Sea worthy Export Packing Standard export and seaworthy packing. (waterproof paper and metal sheet protection with fluted rings at inner and outer edges, 4 eye bands and 4 circumferential bands fasten the coil)

2.Are the products tested before shipping??

Yes, all of our PPGI and GI was qualified before shipping. We test every batch every day.

3.What's your normal delivery time?

Our delivery time about 15-20days for standard sizes, if you have other requirements like hardness, quanity and width ,it is about 20-40days. But don't worry ,we also try our best for the delivery time ,because time longer and our cost is higher.

- Q: How do steel coil manufacturers stay updated with industry trends?

- Steel coil manufacturers stay updated with industry trends by regularly attending industry conferences, trade shows, and seminars where they can network with other professionals and learn about the latest advancements and innovations in the steel coil industry. They also subscribe to industry publications, join professional associations, and participate in online forums and webinars to stay informed about market trends, new technologies, and industry best practices. Additionally, they actively engage with their customers and suppliers to gather feedback and insights, allowing them to adapt and stay ahead of the curve in this rapidly evolving industry.

- Q: Hello,I have been thinking about buying a Tungsten Carbide Diamond wedding band for my husband but one of my family members keep telling me that Tungsten Carbide is merely steel and hence, a low quality metal, therefore, I shouldn't buy it. I don't really know much about it. Please if anyone can tell me more about this metal? Thanks.

- Tungsten is not steel. Tungsten is a chemical element. What they do is add an alloy mixture to tungsten and it turns into Tungsten Carbide. You want to find a ring with a nickel alloy, some manufacturers cheap out and add cobalt instead. Make sure the ring you buy does not contain cobalt. Steel is an alloy consisting mostly of iron, with a carbon.

- Q: How are steel coils used in the manufacturing of building materials?

- Steel coils are used in the manufacturing of building materials as they provide a strong and durable base for various products. These coils are typically unrolled and shaped into different forms, such as sheets or beams, which are then used to create structures like roofing, siding, and framing. The flexibility and strength of steel make it an ideal material for construction purposes, ensuring buildings are sturdy and long-lasting.

- Q: What are the different types of steel coil packaging?

- There are several different types of steel coil packaging methods used in various industries. Some of the commonly used types include: 1. Wooden Crates: Steel coils are often packed in wooden crates for transportation and storage. These crates provide excellent protection against damage and ensure that the coils remain secure during transit. 2. Steel Frame Bundles: In this packaging method, steel coils are tightly strapped together using steel bands or wires. This creates a sturdy bundle that can be easily lifted and moved using cranes or forklifts. Steel frame bundles are commonly used in industries where the coils are required to be stacked vertically. 3. Steel Strapping: Steel coils can also be packaged using steel strapping. Straps are tightly wrapped around the coils to secure them in place. This method provides good protection against movement and damage during transportation. 4. VCI (Volatile Corrosion Inhibitor) Packaging: VCI packaging is ideal for protecting steel coils from corrosion during storage and shipment. It involves wrapping the coils in special VCI film or paper that releases corrosion-inhibiting molecules. This helps to prevent rust and corrosion, ensuring the coils remain in good condition. 5. Cardboard Packaging: Steel coils can be packaged in cardboard boxes or cartons. This method is commonly used for smaller coils or when additional protection is required. The coils are placed inside the box, which is then sealed to provide a protective barrier against damage and contamination. 6. Stretch Wrapping: Stretch wrapping involves wrapping a plastic film tightly around the steel coils, creating a secure and protective layer. This method is commonly used when the coils need to be protected from dust, moisture, or other external elements. Overall, the choice of steel coil packaging method depends on factors such as coil size, weight, transportation requirements, and the level of protection needed. Each method offers its own advantages and is selected based on the specific needs of the industry and the coils being packaged.

- Q: 2 refridgerator of similar model and same brand..one is stainless steel...the other is clear steel (cheaper)..so wat's the difference between the two?

- In okorder /... The appliances that are not made of stainless steel are made of a mild steel which is then finished with a durable enameled finish, in colors even. Stainless steel appliances look very nice in the showroom, but it is no fun trying to keep them fingerprint and handprint free. If you have ever owned a toaster that was made from stainless steel then you know how much fun it would be to have to keep a whole refrigerator fingerprint free, The oils transferred from the skin leave very distinct smears on stainless surfaces.

- Q: What are the common international standards for steel coils?

- The common international standards for steel coils include ASTM A653/A653M, JIS G3302, EN 10346, and GB/T 2518. These standards specify the requirements for the chemical composition, mechanical properties, and dimensions of steel coils used in various industries.

- Q: How are steel coils inspected for oil or rust residues using chemical analysis?

- Chemical analysis techniques can be employed to inspect steel coils for the presence of oil or rust residues. One widely used method is Fourier transform infrared spectroscopy (FTIR), which involves subjecting a small sample of the steel coil to infrared radiation and analyzing the resulting infrared spectrum. By identifying specific chemical bonds indicative of oil or rust residues, this technique can effectively detect their presence. For oil residue detection, a common approach is to examine the FTIR spectrum for a peak at approximately 2920 cm-1, which corresponds to the stretching vibration of C-H bonds in hydrocarbon chains. The observation of this peak signifies the existence of oil residues on the steel coil. To identify rust residues, the FTIR spectrum is scrutinized for characteristic peaks associated with iron oxide or hydroxide compounds. For instance, the presence of a peak at around 560 cm-1 suggests the presence of iron oxide (FeO) or iron hydroxide (Fe(OH)3). Apart from FTIR analysis, other chemical analysis techniques like X-ray fluorescence spectroscopy (XRF) or energy-dispersive X-ray spectroscopy (EDX) can also be employed. These methods provide information about the elemental composition of the steel coil, enabling the identification of specific elements linked to oil or rust residues, such as carbon or iron. In essence, the chemical analysis of steel coils for oil or rust residues offers a dependable and precise means of ensuring the coils' quality and cleanliness before further processing or utilization.

- Q: What are the dimensions of steel coils used in shipbuilding?

- The dimensions of steel coils used in shipbuilding can vary depending on the specific requirements of the ship and its construction. However, commonly used dimensions for steel coils in shipbuilding range from 1.5mm to 25mm in thickness and 600mm to 2000mm in width. The length of the steel coils can also vary, typically ranging from 1000mm to 6000mm. These dimensions are chosen to ensure the strength and durability of the ship's structure, while also considering factors such as weight, flexibility, and ease of handling during the construction process.

- Q: How are steel coils used in the production of metal buildings?

- Steel coils are an essential component in the production of metal buildings as they are used to create the structural framework and outer cladding. These coils are unrolled and cut into sheets, which are then shaped and formed into various building components such as beams, columns, and panels. The strength and durability of steel make it an ideal material for constructing metal buildings, ensuring they are capable of withstanding harsh weather conditions and providing long-lasting structures.

- Q: What are the common coil slitting equipment used in the industry?

- The common coil slitting equipment used in the industry include slitting lines, slitter knives, and tension stands. Slitting lines are machines used to cut a large coil into smaller coils of desired widths. Slitter knives are sharp blades mounted on the slitting line that perform the cutting process. Tension stands are used to control the tension of the coils during the slitting process, ensuring smooth and accurate cuts.

Send your message to us

BMP Z15 PPGI Rolled Steel Coil for Construction Roofing

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m.t.

- Supply Capability:

- 30000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords