BMP Z45 PPGI Rolled Steel Coil for Construction Roofing

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 125 m.t.

- Supply Capability:

- 30000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

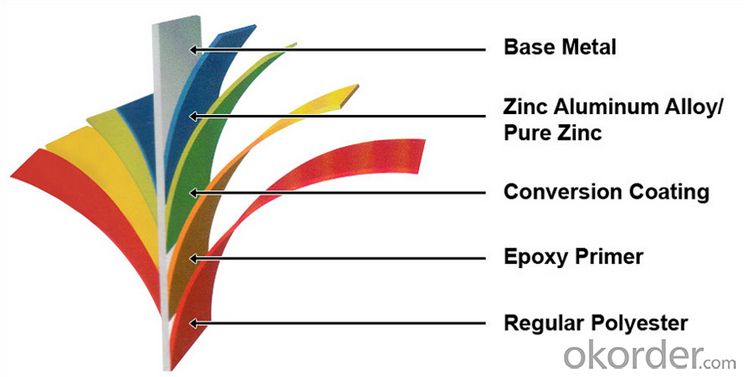

Structure of BMP Z45 PPGI Rolled Steel Coil for Construction Roofing

Description of BMP Z45 PPGI Rolled Steel Coil for Construction Roofing

Color Coated Steel Coil metal has the highest value among all cold-rolled steel products. Produced by printing or baking paints onto the surface of cold-rolled steel or GI or ALCOT sheets, pre-coated metal features a wide range of colors and patterns which are commonly used to make the exterior of buildings and consumer electronics products look more polished and sophisticated. Depending on the specific utility of each product, a vast variety of features are available including pollution resistance and anti-bacterial quality

Main Feature of BMP Z45 PPGI Rolled Steel Coil for Construction Roofing

A. Corrugated design makes it excellent waterproof performance

B. Materials as prepainted steel sheets, galvanized steel sheets, galvalume (Al-Zn coated sheets) are available to make corrugated sheet.

C.Those material are durable, anti-corrosion in bad weather for 20-30 years based on it's Zinc(Galvanized) coating or AZ (Galvalume) coating.

D. Different shape of the sheet make it suitable for any style of buildings.

E.Easy to install, no need special tools to fix the sheet.

F.Light weight due to high strength to weight ratio of steel. Light weight means easier handling lower shipping costs, easier installation

G. Different color is availbe base on the RAL Standard make your building more beautiful.

H. We will provide the best solutions if you don't have a exact idea of the specification you want for the steel sheet based on your weather conditions, engineering structure, construction budget and so on.

Applications of BMP Z45 PPGI Rolled Steel Coil for Construction Roofing

Exterior decoration of buildings: Roof and wallboards of industrial, commercial, residential and public facilities

Interior decoration of buildings: Wallboards, ceiling boards, partition boards, fireproof doors

Building accessories: Window panels, signboards Home appliances: Oil/gas boilers, rice buckets, portable gas burners, etc.

Outdoor: Roof\ Roof structure\Surface sheet of balcony\ Frame of window\Door of garage\Roller shutter door\Persian blinds\Cabana and so on.Indoor: Door\Isolater\Frame of door\Light steel structure of house\\Folding screen\Ceiling\Internal decoration of toilet and elevator.

Building accessories: Window panels, signboards Home appliances: Oil/gas boilers, rice buckets, portable gas burners, etc.

Specifications of BMP Z45 PPGI Rolled Steel Coil for Construction Roofing

Standard | ASTM A653, JIS G3302, GB/T3830-2006 |

Grade | SGCC, DX51D, A653, SGCH, Q235B |

Thickness | 0.125-1.0mm |

Width | 600-1250mm |

Base metal | Galvanized steel coils, Alumzinc steel coils, color coated steel coils |

Zinc coating | 40-275g/M2 |

Coil ID | 508mm/610mm |

Packing | Standard seaworthy export packing: 3 layers of packing, inside is kraft paper, water plastic film is in the middle and outside GI steel sheet to be covered by steel strips with lock, with inner coil sleeve. |

Delivery | Within 10-30days after signing contract |

Price | FOB& CNF& CIF price |

Payment terms | TT or LC, Western Union |

Capacity | 1000MT per month |

MOQ | 25MT/20GP |

Usage | construction, the manufacturing of cars, ships, containers and household electric appliances,other industries usage. |

FAQ of BMP Z45 PPGI Rolled Steel Coil for Construction Roofing

We have organized several common questions for our clients,may help you sincerely:

1.Are you a factory or a trading company?

CNBM is a trading company in this industry over 30 years, located in Beijing

2. Do you accept OA payment terms?

Yes, sure, but it normally depending on the order value.

3.What's your normal delivery time?

Our delivery time about 15-20days for standard sizes, if you have other requirements like hardness, quanity and width ,it is about 20-40days. But don't worry ,we also try our best for the delivery time ,because time longer and our cost is higher.

- Q: I need to identify a metal. It is rusty so I suspect it is either iron or steel. Since they both have similar densities and are magnetic, how do I tell the difference betweeen steel and iron?

- Iron and Steel Manufacture, technology related to the production of iron and its alloys, particularly those containing a small percentage of carbon. The differences between the various types of iron and steel are sometimes confusing because of the nomenclature used. Steel in general is an alloy of iron and carbon, often with an admixture of other elements. Some alloys that are commercially called irons contain more carbon than commercial steels. Open-hearth iron and wrought iron contain only a few hundredths of 1 percent of carbon. Steels of various types contain from 0.04 percent to 2.25 percent of carbon. Cast iron, malleable cast iron, and pig iron contain amounts of carbon varying from 2 to 4 percent. A special form of malleable iron, containing virtually no carbon, is known as white-heart malleable iron. A special group of iron alloys, known as ferroalloys, is used in the manufacture of iron and steel alloys; they contain from 20 to 80 percent of an alloying element, such as manganese, silicon, or chromium.

- Q: All the steel straps that secure my deck and stair 6x6 posts to the concrete piers have some rust on them. Had bought a rust reducer to spray on them and repaint. As I went to do this I found that one of them is on its last legs, with the steel rusted through and bubbling up all up the sides of the straps. Since this is the end post on a row of 3 deck support posts, I was thinking of removing as much rust as possible, then paint with Rustoleum and cover lower post with something to keep water away from post and pier in the future? Was thinking of something removeable so I could check on it for further rusting. What do you folks with building experience think of this? Thanks.

- If these steel straps are rusting through and on their last legs, a coat of paint is going to be cosmetic at best. Replace these straps with new ones. The originals were either very poorly galvanized, or you live someplace with a very corrosive environment. In any event, paint can't save this sort of thing. Steel brackets serve a real purpose, and after they're weakened, they can't do that anymore. How would your home hold up in an earthquake, for example? What you're proposing doesn't sound safe.

- Q: i always have eaten rolled oats and i have never tried steel cut oats. what are your opinions on them for oatmeal and which do u like better?

- Steel cut oats take very long to cook. They have a bit more bite to them but the flavor is really the same. It's more a question of which texture you prefer.

- Q: How are steel coils used in the production of agricultural structures?

- Steel coils are used in the production of agricultural structures as they are the primary material for manufacturing various components like beams, columns, and trusses. These coils are typically shaped, cut, and welded to form the framework for buildings, barns, silos, and other agricultural structures. The strength and durability of steel make it an ideal choice, ensuring that the structures can withstand harsh weather conditions and support heavy loads, making them essential for the agricultural industry.

- Q: How are steel coils used in the manufacturing of pipelines?

- Steel coils are used in the manufacturing of pipelines by being uncoiled and formed into sections that are welded together to create a continuous pipeline.

- Q: What are the main challenges in handling and processing steel coils?

- The main challenges in handling and processing steel coils include their large size and weight, the risk of damage during transportation and storage, the need for specialized equipment and facilities, ensuring proper handling to prevent injury to workers, and addressing the potential for corrosion and rust. Additionally, the variability in coil dimensions and surface conditions can pose difficulties in achieving precise and consistent processing results.

- Q: How do steel coils contribute to the aerospace manufacturing industry?

- Steel coils are essential in the aerospace manufacturing industry as they are used to produce various components, such as aircraft bodies, wings, and landing gear. These coils provide the necessary strength, durability, and resistance to extreme conditions required for aerospace applications. Additionally, steel coils can be easily shaped and welded, enabling manufacturers to create complex and precise structures, thereby enhancing the safety and efficiency of aircraft.

- Q: How are steel coils used in the production of signage?

- Steel coils are used in the production of signage as they provide a durable and versatile material for creating sturdy sign structures. The steel coils are typically cut into desired shapes and sizes, then bent, welded, or formed to create the framework of the signs. This allows for the creation of different types of signs, such as billboards, street signs, or large display signs. The steel coils' strength and resistance to weather make them ideal for outdoor signage that needs to withstand various environmental conditions.

- Q: How do you prevent damage to steel coils during transportation?

- To prevent damage to steel coils during transportation, several measures can be taken: 1. Proper packing and securing: Steel coils should be packed tightly and securely in order to prevent any movement or shifting during transportation. This can be achieved by using appropriate packaging materials such as steel cradles, wooden dunnage, or steel straps to hold the coils in place. 2. Cushioning and padding: Adding cushioning materials such as foam padding, cardboard, or bubble wrap between coils can help absorb shocks and vibrations during transit. This extra layer of protection minimizes the risk of scratches, dents, or other damages caused by contact with other objects or surfaces. 3. Adequate handling and loading: Using proper lifting equipment and techniques is crucial to avoid mishandling and dropping of the steel coils. Forklifts or cranes should be used to lift and load the coils carefully onto transportation vehicles. Additionally, coils should be stacked in a way that distributes weight evenly to maintain stability. 4. Weather protection: Steel coils are susceptible to corrosion, so it is essential to protect them from moisture and adverse weather conditions during transportation. Coils should be covered with waterproof and weather-resistant tarps or shrink wrap to prevent water or moisture from reaching the steel surfaces. 5. Regular inspections: Regularly inspecting the coils before, during, and after transportation is vital to identify any potential damage or issues. This allows for timely intervention to rectify any problems and prevent further damage. 6. Properly trained personnel: Ensuring that personnel involved in handling, loading, and transporting the steel coils are adequately trained is crucial. They should be aware of the proper procedures and techniques to safely handle and transport the coils, minimizing the risk of damage. By implementing these preventative measures, the risk of damage to steel coils during transportation can be significantly reduced, ensuring that the coils reach their destination in optimal condition.

- Q: Do you know of any movies that featured the steel drum?

- You okorder /.. If I can find any clips, I'll add them, but I'm sure that many movies in the proper settings (Trinidad, etc.) would have such music and/or show a group or at least a single performer. For example, Cool Running could be a possibility.

Send your message to us

BMP Z45 PPGI Rolled Steel Coil for Construction Roofing

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 125 m.t.

- Supply Capability:

- 30000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords