Black EPDM Rubber Waterproofing Membrane applt to Bridge/Road

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2000 m²

- Supply Capability:

- 100000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

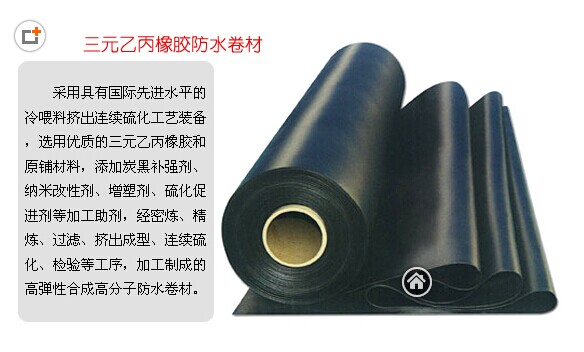

EPDM waterproofing Rubber membrane

1. Product Feature for EPDM Waterproofing Membrane:

a. UV resistant and anti-corrosion

b. High tensile strength and good elongation.

c. Easy installation, solid joint, and no environmental pollution

d. Good rooting penetration resistance

e. Service life up to 50 years

2. Detail Specification of EPDM Waterproofing Membrane:

Type | EPDM Waterproof Membrane | ||

Material | EPDM Rubber | ||

Thickness | 1.2mm | 1.5mm | 2.0mm |

Weight(kg/m2) | 1.54-1.58 | 1.79-1.83 | 2.25-2.29 |

Size | 1.2m(width) * 20m(length)/roll | ||

Type | Vulcanized & Weldable | ||

Pattern | Non-reinforced(homogeneous) | ||

Packing | 24sqm/roll, with plastic bag | ||

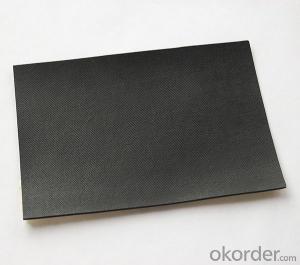

Color | Black | ||

Application | Roof, basement, pond, Lake, steel structure roof, swimming pool, underground, tunnel, etc | ||

3. Technical Sheet of EPDM Waterproofing Membrane:

No. | Item | Technical index | ||

JL1 | JF1 | |||

1 | Tensile strength at break Mpa | Normal temperature≥ | 7.5 | 4.0 |

60°C≥ | 2.3 | 0.8 | ||

2 | Elogation at break | Normal temperature≥ | 450 | 400 |

-20°C≥ | 200 | 200 | ||

3 | Tearing strength KN/m≥ | 25 | 18 | |

4 | Impermeability 30minutes No leak | 0.3Mpa | 0.3Mpa | |

5 | Low temperature flexibility °C≤ | -40 | -30 | |

6 | Heat air ageing 80°C x 168h | Tensile strength retention rate % ≥ | 80 | 90 |

Elogation retention rate % ≥ | 70 | 70 | ||

Apperance of 100% elogation | no crack | no crack | ||

4. Application of EPDM Waterproofing Membrane:

(1) Roofs, Basement, Toilets

(2) Industrial and civil building waterproofing

(3) Geosynthetic liner for swimming pool, channels, irrigation system

(4) Especially suitable for projects with high requirements in durability, anti-corrosion and deformation

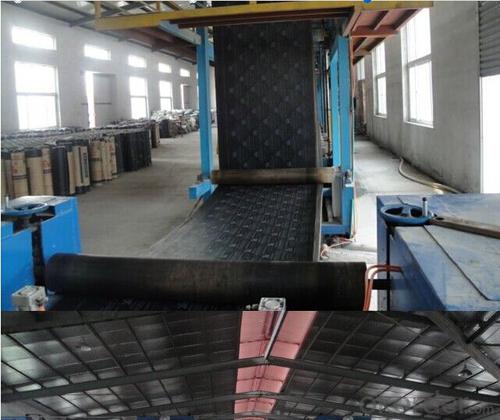

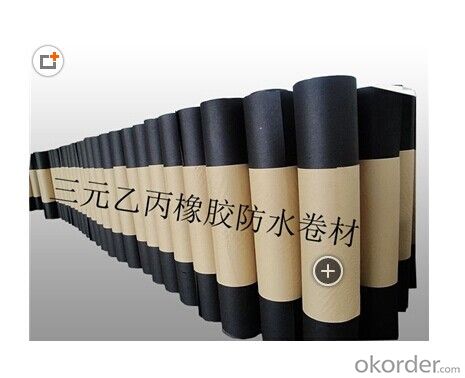

4. Some photos:

- Q: Are there different waterproofing membrane options for above-ground and below-ground applications?

- There is a variety of waterproofing membrane options available for above-ground and below-ground applications. When it comes to above-ground applications, structures like roofs, balconies, or walls require waterproofing. In these cases, commonly used membrane options include liquid-applied membranes, sheet membranes, and polyurethane membranes. These membranes are designed to withstand weather elements, such as UV rays, temperature changes, and foot traffic. On the other hand, below-ground applications involve waterproofing structures like basements, foundations, or tunnels. Below-ground waterproofing membranes are specifically designed to withstand hydrostatic pressure from the surrounding soil and groundwater. These membranes are typically thicker and more durable compared to above-ground membranes. Bituminous membranes, bentonite clay membranes, and composite membranes are commonly used options for below-ground waterproofing. Selecting the appropriate waterproofing membrane for each specific application is crucial due to varying requirements and challenges. Seeking advice from a waterproofing professional or engineer can assist in determining the most suitable membrane option for both above-ground and below-ground applications.

- Q: Does a waterproofing membrane provide any insulation against temperature fluctuations?

- Insulation against temperature fluctuations is not provided by a waterproofing membrane. The main purpose of a waterproofing membrane is to hinder the infiltration of water or moisture into the safeguarded region. It functions as a shield to maintain the structure's dryness and safeguard it from potential water harm. Although it might provide a certain level of thermal resistance based on its thickness and material characteristics, it is not crafted or intended to furnish insulation against temperature fluctuations. In construction, materials such as insulation foam or insulation boards are commonly employed to offer insulation.

- Q: What is the difference between a liquid and sheet-type waterproofing membrane?

- The main difference between a liquid and sheet-type waterproofing membrane is their physical form and application method. A liquid membrane is typically applied as a liquid coating that dries to form a seamless, flexible, and durable waterproofing layer. It is often used for irregular or hard-to-reach surfaces and can be easily applied using a brush, roller, or spray. On the other hand, a sheet-type membrane is a pre-made sheet or roll that is applied to a surface using adhesive or heat welding. It provides a continuous, barrier-like waterproofing layer and is commonly used for large, flat surfaces. Overall, the choice between a liquid and sheet-type membrane depends on the specific project requirements, surface characteristics, and application preferences.

- Q: Can a waterproofing membrane be used on gypsum board surfaces?

- Gypsum board surfaces can indeed benefit from the application of a waterproofing membrane. Drywall, which is another term for gypsum board, is commonly used in interior construction. Although it is not naturally resistant to water, the use of a waterproofing membrane can safeguard the gypsum board from potential moisture-related harm. The waterproofing membrane is a thin layer of material that is carefully applied onto the surface of the gypsum board. It serves as a barrier, effectively preventing water from penetrating the board and causing it to deteriorate or develop mold. This solution is particularly useful in areas where moisture is prevalent, such as bathrooms, kitchens, laundry rooms, or basements. Before proceeding with the application of the waterproofing membrane, it is crucial to properly prepare the gypsum board surface. This entails cleaning the surface, addressing any holes or cracks, and ensuring that the board is thoroughly dry and devoid of dust. Once the surface is adequately primed, the waterproofing membrane can be applied in accordance with the instructions provided by the manufacturer. It is essential to recognize that while a waterproofing membrane can offer some protection against moisture, it does not guarantee complete immunity from water damage. It is always necessary to address the root cause of water intrusion and ensure appropriate drainage and ventilation in any area prone to moisture. Furthermore, it is advisable to seek advice from a professional or adhere to the manufacturer's guidelines when selecting and applying a waterproofing membrane to gypsum board surfaces.

- Q: Can a waterproofing membrane be used on roofs with flat surfaces?

- Roofs with flat surfaces can indeed benefit from the application of a waterproofing membrane. In fact, it is quite common to use these membranes on flat roofs to safeguard against water infiltration. The primary function of these membranes is to establish a barrier that obstructs water from seeping into the roof structure and causing harm. Typically, they are constructed using materials like modified bitumen, EPDM, or PVC, which exhibit great resistance to both water and UV rays. To install the membrane, it can be done by torch-application, adhesive adherence, or mechanical fastening. To ensure optimal effectiveness and longevity of the waterproofing membrane on a flat roof, it is crucial to guarantee proper installation and regular maintenance.

- Q: Can a waterproofing membrane be used for a fountain basin?

- Yes, a waterproofing membrane can be used for a fountain basin. Waterproofing membranes are designed to provide a protective barrier against water penetration, making them an ideal choice for ensuring the fountain basin remains watertight and prevents leakage.

- Q: Can a waterproofing membrane be used on nickel surfaces?

- Yes, a waterproofing membrane can be used on nickel surfaces. Waterproofing membranes are commonly used in construction and building projects to protect surfaces from water damage and moisture intrusion. They create a barrier that prevents water from penetrating through the surface and causing damage. Nickel surfaces, like any other metal surfaces, can be susceptible to corrosion and damage from water exposure. By applying a waterproofing membrane, the nickel surface can be effectively protected from water and moisture, extending its lifespan and maintaining its integrity. However, it is important to ensure that the specific waterproofing membrane being used is suitable for application on nickel surfaces. Different membranes may have different compatibility requirements, so it is recommended to consult with the manufacturer or a professional to ensure proper application and compatibility.

- Q: Can a waterproofing membrane be used in schools or educational buildings?

- Yes, a waterproofing membrane can be used in schools or educational buildings. Waterproofing membranes are commonly used in these types of buildings to protect them from water damage and leakage. By preventing water infiltration, a waterproofing membrane helps maintain a safe and healthy environment for students and staff, preserving the structural integrity of the building and reducing maintenance costs in the long run.

- Q: Can a waterproofing membrane be used on interior walls?

- Yes, a waterproofing membrane can be used on interior walls. Waterproofing membranes are designed to create a barrier against moisture, preventing water from penetrating the surface and causing damage. While they are commonly used on exterior walls to protect against rain and groundwater, they can also be used on interior walls in areas that are prone to moisture, such as bathrooms, kitchens, or basements. By applying a waterproofing membrane, you can effectively protect the interior walls from water damage, mold growth, and other moisture-related issues. It is important to note that the specific type of waterproofing membrane and the proper installation technique should be determined based on the specific needs and conditions of the interior walls. Consulting with a professional or following manufacturer guidelines is recommended to ensure proper application and long-lasting protection.

- Q: Can a waterproofing membrane be used in crawl spaces?

- Crawl spaces, being susceptible to moisture and water intrusion, can suffer from issues like mold, mildew, and structural damage. For protection against water damage, using a waterproofing membrane is an effective solution. By installing the membrane on the walls and floor of the crawl space, it creates a barrier that keeps moisture out. This is especially useful in areas with high water table levels or frequent flooding. Moreover, the waterproofing membrane not only safeguards the crawl space but also enhances indoor air quality by inhibiting mold growth and reducing allergens. To determine the most suitable waterproofing membrane and installation method for a specific crawl space, it is advisable to seek professional advice as requirements may differ.

Send your message to us

Black EPDM Rubber Waterproofing Membrane applt to Bridge/Road

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2000 m²

- Supply Capability:

- 100000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords