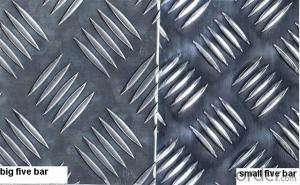

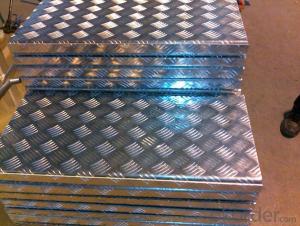

Aluminum Trailer Skin Sheets - Big/Small Five Bar Treadplate Series 1/3/5

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 3 m.t.

- Supply Capability:

- 9000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

1. Specifications of Big Five Bar Treadplate

Original Price | USD1930 |

Current Price | USD1850 |

Alloy | AA1100 CC |

Temper: | H12, H14, H16, H18, H22, H24, H26, H32,HO, F |

Thickness: | 1.5mm- 1.0mm |

Width: | 1000mm-1300mm |

Standard: | GB/T17748-1999, ASTM, ISO, EU standard |

Special Specification is available on customer’s requirement | |

2. Usage/Application of Big Five Bar Treadplate

The embossed aluminum coil/sheet are widely used for decorative purpose in construction, packing and appliance. It is also very commonly used for anti-splippery purposes in vehicles and public places.

3. Packaging & Deliveryof Big Five Bar Treadplate

Seaworthy package, plastic bag covered inside, carton wrapped outside, paper core, on the wooden pallet. Pallet weight: 2000-25000KG.

Shipment: The goods will be delivered in not more than 40 days after getting the buyer's prepayment.

4. Production Flow of Big Five Bar Treadplate

Melting-Rolling- Cutting- Annealing--Packing

- Q: An aluminum engine block has a volume of 4.77 and a mass of 12.88 .

- For the best answers, search on this site okorder (2.7 g / cm?) x (1 kg / 1000 g) x (100 cm / 1 m)? = 2700 kg / m?

- Q: need help choosing an aluminum welder at a descent price also

- i think, welding,,, tig is right machine for aluminum, thank you.

- Q: Are aluminum sheets suitable for laser cutting?

- Indeed, laser cutting is a suitable method for aluminum sheets. Aluminum, which possesses exceptional reflective properties, high thermal conductivity, and a low melting point, is extensively employed in laser cutting operations. These remarkable attributes render it a prime candidate for being sliced by a laser beam. Laser cutting ensures accurate and neat incisions on aluminum sheets, enabling the effortless realization of intricate patterns and intricate forms. Moreover, laser cutting for aluminum sheets guarantees rapid and efficient processing, delivering enhanced productivity and cost-effectiveness.

- Q: I want to make a part using molten aluminum with a hole through the middle and would like to use a steel rod to do this. Would the bar stick to the aluminum when it cools and not be able to be removed? If so is there so type of coating I can use so it can be removed?

- Aluminium and iron are pretty incompatible materials, they don't form an alloy I don't think, so it is unlikely they would stick. Also, both metals will get an oxide layer on the surface which should keep them separate. Try it! If the finished part does stick, try heating the aluminium then dip the steel rod in some ice water.

- Q: Can aluminum sheets be hydroformed?

- Yes, aluminum sheets can be hydroformed.

- Q: I need to know what composite bats do and how (or if) they are better than aluminum bats.

- This Site Might Help You. RE: What is the difference between composite bats and aluminum bats? I need to know what composite bats do and how (or if) they are better than aluminum bats.

- Q: Are the aluminum sheets suitable for manufacturing architectural wall panels?

- Architectural wall panels can be manufactured using aluminum sheets, which offer various benefits and are widely used in the construction industry. Aluminum is a versatile and popular material due to its many advantages. To start, aluminum is lightweight, making it easy to handle and install. This is especially advantageous for architectural wall panels as it reduces the overall weight of the structure, simplifies transportation, and allows for greater design flexibility. In addition, aluminum provides exceptional durability and resistance to corrosion. This is crucial for wall panels as they are exposed to environmental elements such as rain, UV rays, and temperature changes. The natural oxide layer of aluminum acts as a protective barrier, ensuring the panels remain intact and maintain their appearance over time. Moreover, aluminum offers excellent thermal and acoustic insulation properties. Architectural wall panels made from aluminum can help regulate the internal temperature of buildings, resulting in energy savings and improved comfort for occupants. Furthermore, aluminum panels contribute to a quieter indoor environment by reducing noise transmission. Furthermore, aluminum can be customized in terms of shape, size, color, and finish. This allows architects and designers to create visually appealing wall panel systems that complement the overall aesthetics of a building. The versatility of aluminum sheets also enables the integration of other materials, such as glass or stone, for additional design possibilities. Lastly, aluminum is a sustainable material. It is 100% recyclable, and the energy required for recycling aluminum is significantly lower compared to the production of primary aluminum. By choosing aluminum sheets for architectural wall panels, one can promote environmentally friendly practices and contribute to the reduction of carbon emissions. In conclusion, the characteristics of aluminum, including its lightweight nature, durability, resistance to corrosion, thermal and acoustic insulation properties, design flexibility, and sustainability, make it highly suitable for manufacturing architectural wall panels.

- Q: Can aluminum sheet be used for automotive body-in-white applications?

- Certainly, automotive body-in-white applications can utilize aluminum sheet. Aluminum possesses the advantageous qualities of being lightweight, robust, and long-lasting, rendering it an optimal substance for automotive purposes. It presents a remarkable strength-to-weight ratio, which contributes to enhancing fuel efficiency and overall vehicle performance. Furthermore, aluminum excels in resisting corrosion, enabling it to endure harsh environmental conditions. Its malleability permits the creation of intricate and sophisticated designs, empowering manufacturers to fabricate automotive structures that are simultaneously light and sturdy. In recent times, the utilization of aluminum in automotive body-in-white applications has gained considerable popularity, primarily due to its ability to decrease vehicle weight and emissions while simultaneously maximizing safety and performance.

- Q: How much weight/people can a 12ft aluminum boat hold?and if anyone knows how much weight can a 6.5hp motor push around

- 12 Ft Aluminum Boats

- Q: What are the distinctions between standard and custom-made aluminum sheets?

- <p>Standard aluminum sheets are mass-produced with fixed dimensions and specifications, making them readily available and cost-effective. They are suitable for common applications where specific dimensions are not a priority. Custom-made aluminum sheets, on the other hand, are tailored to meet specific requirements regarding size, thickness, and other properties. They offer flexibility for unique applications but may be more expensive and have longer lead times due to the specialized manufacturing process.</p>

Send your message to us

Aluminum Trailer Skin Sheets - Big/Small Five Bar Treadplate Series 1/3/5

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 3 m.t.

- Supply Capability:

- 9000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords