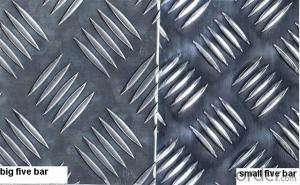

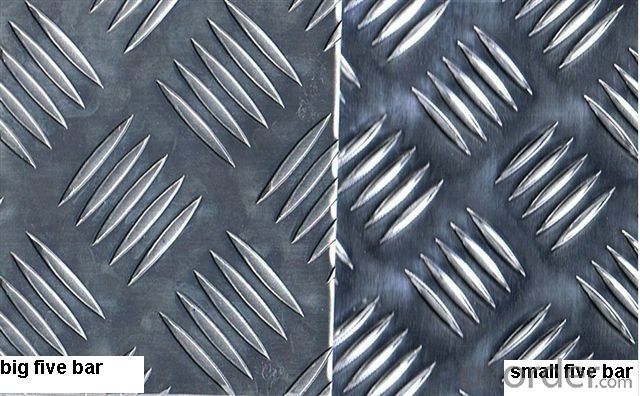

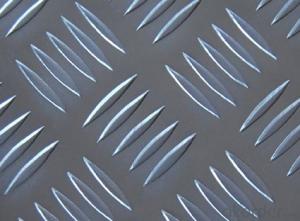

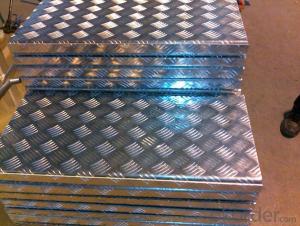

Big Five Bar Treadplate Aluminum Mesh Filter Sheets

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

BIG FIVE BAR TREADPLATE

1. Alloy: AA1XXX, AA3XXX

2. Temper: O-H112

3.Ridge Length: 38mm; Ridge height:0.8-1.2mm

4.Thickness: 1.0-6.0mm

5.Width: 500-2300mm

6.Length: 500-10000mm

7.Main application:

1)Transport vehicles

2)Industrial sheds

3)Fabrication industry

8. Payment: T/T or LC at sight

9. Delivery time: 20 Days

10. Packing:

(1) EPE: protect aluminum.

(2) Plastic sheet: water-proof

(3 )Carton:anti-shock.4 Steel bar: fix

11. Quality: Mill Finish, Totally free from defects like White Rust, Roll Marks, Edge damage,Camber,Dents,Holes,Break Lines, Scratch

- Q: Can aluminum sheets be used for decorative or architectural purposes?

- Yes, aluminum sheets can be used for decorative or architectural purposes. Due to their lightweight, durability, and versatility, aluminum sheets are commonly used in architectural design and construction for applications such as cladding, roofing, facades, and decorative elements. They offer various finishes, patterns, and colors, making them suitable for enhancing the aesthetic appeal of both interior and exterior spaces. Additionally, aluminum sheets are resistant to corrosion and require minimal maintenance, making them a popular choice for decorative and architectural purposes.

- Q: This question asks for an explanation of the various types of paint that can be applied to aluminum sheets.

- <p>Aluminum sheets can be coated with different types of paints to enhance their appearance, durability, and functionality. The common types include: 1) Acrylic Paints: Known for their flexibility and resistance to weathering and UV rays. 2) Polyester Paints: These offer excellent adhesion and gloss. 3) Epoxy Paints: Known for their chemical resistance and durability. 4) Polyurethane Paints: They provide a tough, scratch-resistant finish. 5) Powder Coatings: These are electrostatically applied and offer a durable, weather-resistant finish. 6) Fluoropolymer Coatings: They provide excellent resistance to chemicals and UV degradation. Each type has specific properties that make it suitable for different applications and environments.</p>

- Q: What precautions should be taken to ensure safety while installing aluminum sheets?

- <p>When installing aluminum sheets, safety measures include wearing appropriate personal protective equipment (PPE) such as gloves, safety glasses, and hard hats. Ensure the work area is clear of debris and any tripping hazards. Use ladders and scaffolding that are in good condition and set up correctly. Always have a spotter when lifting heavy sheets and use proper lifting techniques to avoid back injuries. Keep hands and feet away from edges and corners to prevent cuts. Ensure all tools are in good working order and use them correctly. Follow all manufacturer's guidelines for installation and adhere to local safety regulations.</p>

- Q: What are the different methods of surface protection for outdoor aluminum sheet?

- There are several methods of surface protection for outdoor aluminum sheet to ensure its durability and longevity. 1. Anodizing: This is one of the most common methods used to protect aluminum surfaces. Anodizing creates a protective oxide layer on the surface, making it more resistant to corrosion, abrasion, and UV rays. It also improves the appearance of the aluminum sheet by providing a range of colors and finishes. 2. Powder coating: Powder coating involves applying a dry powder to the aluminum sheet and then baking it in an oven to create a hard, protective coating. This method provides excellent resistance to weathering, corrosion, and chemicals. It is also available in various colors and finishes. 3. Paint coating: Applying a paint coating is another effective way to protect outdoor aluminum sheets. The paint forms a barrier between the aluminum surface and the environment, preventing corrosion and enhancing aesthetics. It is important to use a high-quality paint specifically designed for aluminum to ensure proper adhesion and durability. 4. Clear coating: Clear coating is mainly used to protect the natural appearance of aluminum while providing a layer of protection against corrosion, oxidation, and UV rays. It is often applied after anodizing or polishing the aluminum sheet. 5. Laminating: Laminating involves adhering a protective film or sheet onto the aluminum surface. This method provides excellent resistance to scratches, abrasion, and UV rays. It is commonly used in applications where the aluminum sheet is subjected to heavy wear and tear. 6. Chemical conversion coating: Chemical conversion coatings, such as chromate conversion coating or phosphating, are used to improve the corrosion resistance of aluminum sheets. These coatings chemically react with the surface to create a protective layer that inhibits corrosion. It is important to consider the specific requirements and environmental conditions when choosing a method of surface protection for outdoor aluminum sheets. Each method has its own advantages and limitations, and the choice should be based on factors such as durability, appearance, cost, and maintenance requirements.

- Q: If I were to make an aluminum mold and cover it with a release agent, could I cast aluminum into it? Or would the two parts fuse together? I'm trying to find an alternative to sand casting.Thank you!

- This may be a little more difficult but offers better detail than sand casting. Lost wax casting Investment or ceramic shell You can make molds to form the wax but investment or ceramic shell are destroyed in the process

- Q: Aluminum knowledge. What is the model 3003 H24? What does H mean?

- 3003 is aluminium manganese alloy aluminum plate (Al--Mn), which is mainly composed of manganese.H24: continuous casting, continuous rolling, Zhang Liqiang and partial toughening.Is the aluminum plate with a thickness of more than 0.2mm to 500mm, 200mm width, length less than 16m aluminum material called aluminum plate or aluminum sheet, aluminum is below 0.2mm, 200mm within the width of the row material or bar (of course, with the progress of the large equipment, the width can be 600mm row material also more). Aluminum sheet refers to the rectangular plate made of aluminium ingot rolled and divided into pure aluminum plate, alloy aluminum plate, thin aluminum plate, middle thick aluminum plate and pattern aluminum plate.Aluminium alloy is added in the process of aluminum alloy elements (main alloying elements copper, silicon, magnesium, zinc, manganese, minor alloying elements such as nickel, iron, chromium, titanium, lithium, etc.) in order to improve the mechanical properties of aluminum and chemical index. Alloy aluminum sheet has some special properties of pure aluminum plate, and is widely used in special environment, such as ship, refrigerator, mould, aerospace equipment, etc..

- Q: If you're familiar with some of my previous questions, you'll know I have a thing for DC-3's, and I'd like to buy one and fix it up at some point in my life. I was looking at pictures on Google for my desktop background and saw several with shiny chrome/aluminum bodies. Well, first of all, is it chrome or polished aluminum? Second, would I be able to buy a DC-3 painted this God-awful forest green and put whatever it is (chrome/aluminum) on said plane? Or is it something that the plane has to be built with originally?

- Polished aluminum... airplanes are not chrome plated... weight and the difficulty of electro-plating an entire aircraft are the reasons Could likely get some dissimilar metal corrsosion problems as well... Polished aluminum airplanes are absolutely beautiful, but it takes an incredible amount of work to get it that way, and a nearly equal amount of work to keep it up... plan on spending lots of time, money or both...

- Q: Can 101 aluminum sheets be used in electrical or electronic components?

- Yes, 101 aluminum sheets can be used in electrical or electronic components.

- Q: What are the different surface treatments available for aluminum sheets?

- Some of the different surface treatments available for aluminum sheets include anodizing, painting, powder coating, and polishing. Anodizing provides a durable and corrosion-resistant finish by creating an oxide layer on the surface of the aluminum. Painting involves applying a coat of paint to the sheet, which can provide both protection and aesthetic appeal. Powder coating is a process where a dry powder is applied to the aluminum and then heated, creating a durable and vibrant finish. Polishing involves buffing the surface of the aluminum to create a smooth and reflective finish.

- Q: How do aluminum sheets perform in terms of weather resistance?

- Aluminum sheets possess remarkable properties when it comes to resisting weather. Their innate ability to resist corrosion enables them to endure exposure to various weather conditions without deteriorating or rusting, making them highly suitable for outdoor uses. The natural formation of a protective oxide layer on the surface of aluminum acts as a barrier against moisture, preventing the metal from reacting with oxygen and thereby reducing the risk of corrosion. Moreover, aluminum sheets exhibit a high resistance to UV radiation, which means they can withstand prolonged exposure to the sun without fading or discoloration. In conclusion, aluminum sheets exhibit outstanding weather resistance and are a dependable choice for a wide range of outdoor applications, such as roofing, siding, and outdoor signage.

Send your message to us

Big Five Bar Treadplate Aluminum Mesh Filter Sheets

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords