Bead Wire for Making Tires with Good Quality

- Loading Port:

- Guangzhou

- Payment Terms:

- TT or LC

- Min Order Qty:

- 600 kg

- Supply Capability:

- 30000 kg/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1. Product Introduction

Bead wire is the steel wire made of high-carbon steel whose surface is plated with red copper or bronze. Bead wire is applied in all types of tires, including car tires, truck tires, aircraft tires, motorcycle tires and bicycle tires. It has a high strength, a good flexibility, a supreme fatigue property and an excellent linearity, which can be adhered to the rubber easily, and is mainly used in the tire bead as the reforcing materials.

2. Product Characteristic

Our product has the following characteristics: high tire safety factor reduce the tire manufacturing cost, adapt to the requirements of the tire industry; It also has the feature of resistance to impact, elongation at break, torsion of high and low torque

The adhesive force is excellent, and the coating process is stable, and the coating process is superior and stable.

3. Product Specification

Specification (mm) | Tolerance (mm) | Tensile Strength(N) | Min Elongation (%) | Torsion (time/360°L=100d) | Coating Weight(g/kg) |

NT | |||||

0.95 | ±0.02 | ≥1850 | 5 | 50(L=200d) | 0.30-0.80 |

0.96 | ±0.02 | ≥1850 | 5 | 50(L=200d) | 0.30-0.80 |

1.20 | ±0.02 | ≥1850 | 5 | 25 | 0.20-0.60 |

1.26 | ±0.02 | ≥1750 | 5 | 25 | 0.20-0.60 |

1.42 | ±0.02 | ≥1750 | 5 | 20 | 0.20-0.60 |

1.55 | ±0.02 | ≥1750 | 5 | 20 | 0.15-0.45 |

1.60 | ±0.02 | ≥1750 | 5 | 20 | 0.15-0.45 |

1.65 | ±0.02 | ≥1750 | 5 | 20 | 0.15-0.45 |

1.83 | ±0.02 | ≥1500 | 5 | 20 | 0.15-0.45 |

2.0 | ±0.02 | ≥1500 | 5 | 20 | 0.15-0.45 |

Apart from the NT, we also have the HT, and the specific specification is according to your requirement.

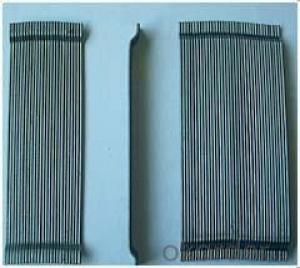

4. Reference Picture

- Q: I want to know what the definition is of a hot wire gauge.

- A hot wire gage is a tool that tells you which wire(s) are hot meaning that they have electricity running through them. If you go to the tool store you would ask for a voltage detector. These are about the size of a pen. They light up and beep when the detect voltage. I highly recommend having one when doing electrical. There is nothing worse than grabbing a wire that you thought was powered off only to get lit up. Hope this helps.

- Q: Which of the following wires would tend to have the least amount of electrical resistance? a) long b) fiberglass c) hot d) thick

- Resistance is directly proportional to the length of the wire, so a long wire will not have the least resistance. Fiberglass is an insulator, not a conductor, so its resistivity will be off the chart a hot wire has more particles moving around and more stuff for free charge to bump in to. so its out. That leaves thick wire as the one that with all other factors equal, will have the lowest resistance.

- Q: wire is 4.5 ft from the pole. (a) How much wire is used? (b) How high up the pole is the wire connected?

- Wire length = 4.5' / cos 80 degrees = 25.91 feet Distance up the pole to where the wire is connected = 4.5' (tan 80 degrees) = 25.52 feet

- Q: Wire 1 and wire 2 are made from the same metal. Wire 2 has a larger diameter than wire 1. The electric field strengths E1 and E2 are equal. A) Compare the values of the two current densities. Is J1 greater than, less, or equal to J2?B) Compare the values of the currents I1 and I2. Is I1 greater then, less or equal to I2?

- The current will be more dense in the smaller wire. The value of the current is inversely proportional to the resistiance of the wire. Resistance = resistivity * length / Area since the wires are of identical material and length, the only thing left to vary is the cross-sectional area. Area is proportional to the square of the radius (diameter), so the current will be proportional to the square of the diameter. I2 is proportional to I1^2 I2 is larger than I1 .

- Q: Suppose we have a 10v battery.one end of the battery is at 10V electric potential and other is at 0V Hence,the potential difference is 10V.if we measure the voltage( p.d.) across positive terminal at 10V and the middle of the wire connecting both ends of battery will it be less??I mean,at the middle of the wire the electric will not be zero,right??(correct me if am wrong)Thanks!!

- You are right.

- Q: A wire has resistance 56.8 ohms. If another wire consists of the same material but has twice the length and half the diameter of the first, what is the resistance of the 2nd wire?

- Resistance = rho * L/A where rho = resistivity of the material, so it's the same for both wires. You've doubled the length, and you've divided the area by a factor of 2^2 = 4. Calculate rho * (2L)/(0.25A) and compare that to rho * L/A.

- Q: What role does the neutral wire play?

- It provides the return current path. Without it positive current would have no where to flow once it enters a device. Here's why: Think about you sink... you need a pipe to bring the water in, this is the hot wire. Without a drain the water has no where to go to, this is the neutral wire. Without a drain there is no net flow of water.

- Q: Theres a Green Illumination wire from the factory setup, where do I connect that wire too on my aftermarket deck? Also theres a White/Blue wire that I dont know where it connects either?

- The green illumination wire controlled the dimming on the factory stereo, but it will only apply if your tuner has the same feature. If it doesn't then just put a crimp cap on it and stow it out of the way. As for the white/blue wire, I'm not sure. If you pick up a wiring diagram, such as found in the Hanes manual, it will give you the breakdown. Not all the wiring in your car needs to be hooked up, just the ones that operate the tuner's functions and audio; if everything works and there's no left over wiring from your tuner's wiring bundle, then you don't need that white/blue wire. Crimp it off and tie it up to the bundle. This should be applicable to your year: Radio Constant 12V+ Wire: Blue/Yellow Radio Switched 12V+ Wire: Gray Radio Ground Wire: Brown Radio Illumination Wire: Green Radio Dimmer Wire: N/A Radio Antenna Trigger Wire: N/A Radio Amp Trigger Wire: N/A Front Speakers Size: 4″ Front Speakers Location: Dash Left Front Speaker Wire (+): Pink Left Front Speaker Wire (-): Purple Right Front Speaker Wire (+): Purple Right Front Speaker Wire (-): Light Green Rear Speakers Size: 4″ Rear Speakers Location: Rear Deck Left Rear Speaker Wire (+): Black Left Rear Speaker Wire (-): Yellow Right Rear Speaker Wire (+): Red Right Rear Speaker Wire (-): White

- Q: I live in a condo and Im trying to wire a new light. When I wire it, it stays on constantly despite hitting the switch.The wiring Im dealing with is as follows.At the switch on the wall, there is a red wire, brown wire connected to the switch. A green wire connected to the box in the walll behind the switch.In the ceiling there is a brown wire, green wire, and a white wire wrapped with an unstripped red wire.Coming from the fixture are black, white, green.Ive tried connected black-brown, white-white green-green but the light stays on no matter what. Also tried white-brown, black-white, green to bolt. Still the same thing happens.Not sure what to do.

- Assuming (and one never should) that the red wire at the switch is actually stripped and around one of the two terminal screws, then it should be correct, previously this ceiling box must have been being used for possibly a smoke detector or anything that they wanted to remain hot... but you should be able to (and either turn off the breaker, remove the fuse, or at least make certain that the switch is in the off position if you can, and look closely, often they get installed upside down, but dont confuse this with three and four way light circuits, lol) strip this end of the red wire at the ceiling box and wire nut green to green, white to white, and the remaining black (should be) from the light fixture to the red you stripped, this should solve the problem for you. Michael

- Q: My starter I replaced has 3 wires, two red and one black. Where does each wire go? Pictures would be very helpful if possible

- based upon the gauge you have... i do no longer think of you're placing it to a mustang yet i detect genuine low-priced air stress gauges are very deceptive.. your 5.0 may well be 50 psi (if it relatively is prolonged each and every of how out) and is a great way overinflated. the properly suited tire stress is the two interior the glove container on a plaque interior the door or is a sitcker on the rear door section.. yet stress could desire to be form of 32 psi (220 kps for our metric friends) on your motor vehicle in case you haven't any longer pushed it for greater effective than 8 hours...

Send your message to us

Bead Wire for Making Tires with Good Quality

- Loading Port:

- Guangzhou

- Payment Terms:

- TT or LC

- Min Order Qty:

- 600 kg

- Supply Capability:

- 30000 kg/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords