Base Reinforcement Geogrids - High Density Polyester HDPE PP Welding Fiberglass PP/PET Geogrid for Roadbed Bridge

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 500 m²

- Supply Capability:

- 100000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

High tensile Strength Polyester Biaxial Geogrid

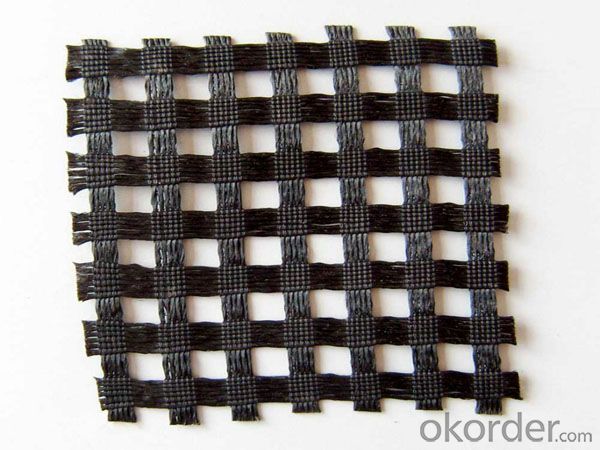

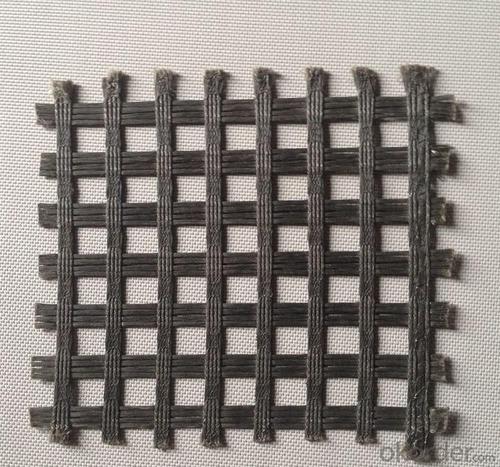

Polyester Biaxial Geogrid Introduction

High tensile Strength Polyester Biaxial Geogrid select high strength synthetic fiber as raw material, adopt warp knitting oriented structure, and no curving between latitude and longitude fiber, use high strength filament on the intersection point to from firm bonding point, and fully perform the mechanical property.

Polyester Biaxial Geogrid Feature

Warp-knitting polyester geogrid has the characteristics such as high strength, high modulus, low elongation, anti-ageing, and anti-brittle, high tensile strength, high tear strength, strong bonding force with gravel and soil, and multiple pre-designed.

Polyester Biaxial Geogrid Application Range

Strengthening weak sub grades of high-grad roads and railways, and separating different foundation soil materials.

Used in riverbank, slope and earth-preserving wall.

Enhancing varieties of the foundation.

Used in airport runway.

Polyester Biaxial Geogrid Technical Parameter

HPET Bi-grid

Project/Size | PET 150-150 | PET 200-200 | PET 260-260 | PET 300-300 | PET 350-350 | PET 400-400 | PET 500-500 | PET 600-600 | PET 700-700 | PET 800-800 | PET 900-900 | PET 1000-1000 | |

Elongation rate % | ≤13 | ≤13 | ≤13 | ≤13 | ≤13 | ≤13 | ≤13 | ≤13 | ≤13 | ≤13 | ≤13 | ≤13 | |

Intensity (KN/m) | vertical | 150 | 200 | 260 | 300 | 350 | 400 | 500 | 600 | 700 | 800 | 900 | 1000 |

Horizontal | 150 | 200 | 260 | 300 | 350 | 400 | 500 | 600 | 700 | 800 | 900 | 1000 | |

Grid size (mm) | 25×25 40×40 50×50 | ||||||||||||

Width (m) | 1-6 | 1-6 | 1-6 | 1-6 | 1-6 | 1-6 | 1-6 | 1-6 | 1-6 | 1-6 | 1-6 | 1-6 | |

Packaging & Delivery

| Packaging Details: | plastic pipe + black PE membrane |

| Delivery Detail: | one 40HQ within 15 days after receipt of T/T or L/C at sight |

FAQ

1. How about the delivery time?

Lead time since receipt of 30% T/T deposit payment: 3 weeks.

2. What kind of payments does jenor support?

T/T, L/C, Cash are accepted.

3. What's are the MOQ?

We can according to your condition to set the MOQ.

And we can provide you samples for quality inspection.

4. Do you charge for the samples?

Accordeing to our company policy, the samples are freee, we only charge the freight fee. And we will return the freight fee If you set the order .

5. Can you produce the product according to customers' requirements ?

Sure, we are professional manufacturer, OEM and ODM are both welcome.

6. Can you tell me your main customers?

That's our customers' privacy, we should protect their information. At the same time, please rest assured that your information is also safe here.

- Q: How do geogrids help in reducing the risk of pavement rutting?

- Geogrids help in reducing the risk of pavement rutting by improving the structural integrity of the pavement. They are placed within the pavement layers to distribute the load more evenly, increasing the pavement's resistance to deformation and rutting. The geogrids create a reinforced layer that enhances the load-bearing capacity and stability of the pavement, preventing the formation of ruts and prolonging its lifespan.

- Q: How do geogrids help in reducing maintenance costs?

- Geogrids help in reducing maintenance costs by providing reinforcement to the soil, increasing its stability and load-bearing capacity. This prevents the need for frequent repairs and maintenance due to soil erosion, settlement, or structural failures. Geogrids also improve drainage, reducing the accumulation of water and preventing damage to the infrastructure, thereby minimizing maintenance expenses in the long run.

- Q: Can geogrids be used in ground improvement projects?

- Yes, geogrids can be used in ground improvement projects. Geogrids are commonly used to reinforce and stabilize weak soil, enhance load-bearing capacity, and prevent soil erosion. They are effective in retaining walls, embankments, road construction, and other ground improvement applications.

- Q: Is there any difference between glass fiber grille and geogrid

- Geogrid also includes polyester grille, steel plastic grille, plastic grille, etc.!

- Q: How do geogrids improve the stability of landfills?

- Geogrids improve the stability of landfills by providing reinforcement and support to the waste materials, preventing slope failure and maintaining the overall integrity of the landfill structure.

- Q: Can geogrids be used in retaining walls?

- Yes, geogrids can be used in retaining walls. Geogrids are commonly used in retaining wall construction to provide additional stability and reinforcement to the structure. These geosynthetic materials are designed to improve the overall strength and performance of the retaining wall by distributing the forces exerted on it and preventing soil movement.

- Q: Are geogrids effective in preventing soil erosion around pipelines?

- Yes, geogrids are effective in preventing soil erosion around pipelines. Geogrids are engineered materials that provide reinforcement and stabilization to the surrounding soil. They create a barrier that helps prevent soil movement and erosion caused by water flow or other environmental factors. Geogrids also distribute the weight and stress of the pipeline more evenly, reducing the chance of soil settlement and potential damage. Overall, geogrids play a crucial role in protecting pipelines from soil erosion and ensuring their long-term stability.

- Q: How do geogrids improve the performance of geosynthetic-reinforced walls?

- Geogrids improve the performance of geosynthetic-reinforced walls by providing a stable reinforcement layer that enhances the strength and stability of the structure. These materials help distribute the load and reduce stress on the wall, preventing potential failures such as wall deformation, sliding, or collapse. Geogrids also enhance the interaction between the soil and the wall, increasing the overall bearing capacity and improving the long-term performance of the reinforced structure.

- Q: Are geogrids suitable for reinforcement of mechanically stabilized aggregate base layers?

- Yes, geogrids are suitable for reinforcement of mechanically stabilized aggregate base layers. Geogrids are designed to improve the strength and stability of soil or aggregate layers by distributing loads more efficiently and reducing lateral movement. They can enhance the performance and lifespan of mechanically stabilized aggregate base layers by increasing their load-bearing capacity, reducing rutting, and preventing the formation of cracks.

- Q: What are the standards for geogrid testing and certification?

- The standards for geogrid testing and certification typically include various parameters such as tensile strength, junction strength, aperture size, creep behavior, and durability. These tests are conducted according to industry-recognized standards such as ASTM D6637, ISO 10319, and GRI-GG2. The certification process ensures that geogrids meet the required performance criteria and can be used effectively in geotechnical applications.

Send your message to us

Base Reinforcement Geogrids - High Density Polyester HDPE PP Welding Fiberglass PP/PET Geogrid for Roadbed Bridge

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 500 m²

- Supply Capability:

- 100000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords