Polyester/ Fiberglass Geogrid/ PP Biaxial Geogrid for Road Construction

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5000 m²

- Supply Capability:

- 1000000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Introduction of Fiberglass Geogrid:

Fiberglass geogrid is based on fiberglass woven cloth coated with modified bitumen or PVC, it was developed to address the problem of pavement cracking on highways, roads and runways, driven by a need to reduce cost for infrastructure maintenance and repair.

It is characterized by high tensile strength in axial and lateral directions, low stretch rate, alkali-resistance, low temperature- resistance, as well as convenience in construction and low price. It can be used on pitch pavement to prevent cracks and prolong pavement service life. It also can be used as a basal reinforcement material for hillsides, reservoirs, harbors, ports, water channels, seawalls, etc.

Performance of Fiberglass Geogrid:

--- High strength, high modulus and low temperatures resistance.

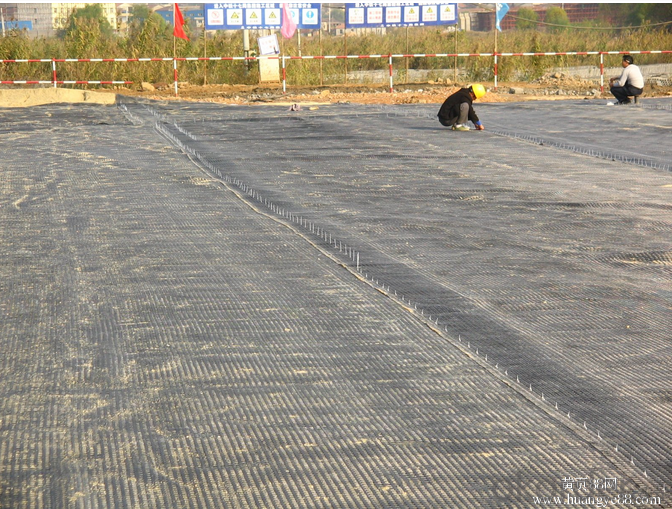

Applications of Fiberglass Geogrid:

--- Reinforcement for road pavement

--- Reinforcement for railway basement

--- Reinforcement for Tunnel

--- Reinforcement for Slope

--- Reinforcement for embankment.

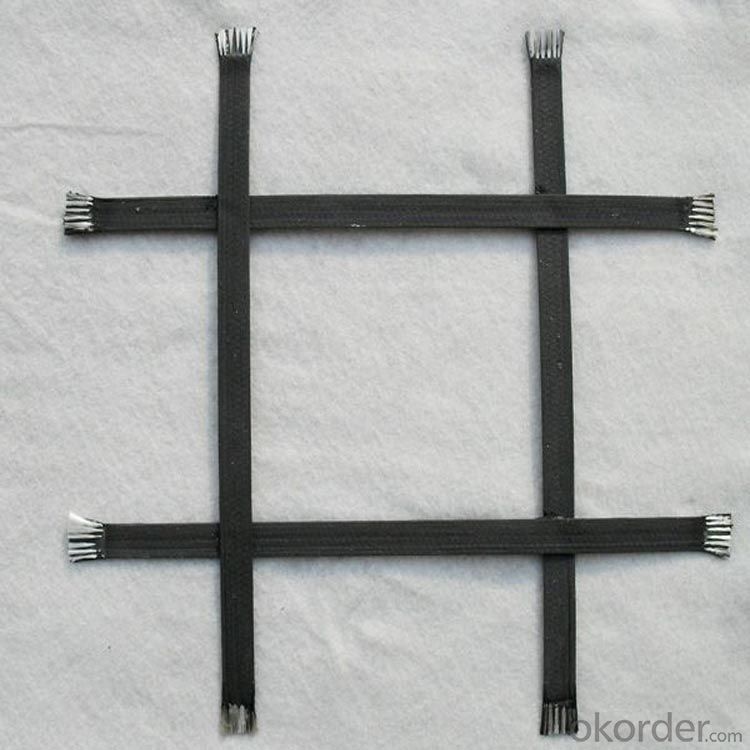

Introduction of PP Biaxial Geogrid:

Biaxial geogrid, made of high molecular polymer, is extruded into sheet and then punched into regular mesh pattern, and finally stretched in longitudinal and transverse directions.

Features of PP Biaxial Geogrid:

1. With high tensile strength in longitudinal and transversedirections

2.This structure can provide an chain system of more effective force bearing and spreading for the soil.

Application of PP Biaxial Geogrid:

Mainly applied in highway, railway, slope protecting projects etc.

1)strengthen land loading capacity and extend its service life.

2) convenient to construct ; reducing project cost and maintenance cost.

Introduction of PP/HDPE Uniaxial Geogrid:

Uniaxial geogrid, made of high molecular polymer, is extruded into sheet and then punched into regular mesh pattern, and finally stretched in the longitudinal direction.

Features of PP/HDPE Uniaxial Geogrid:

With high tensile strength and tensile modulus

Application of PP/HDPE Uniaxial Geogrid:

Mainly applied in highway, railway, slope protecting projects, retaining wall, dam etc.

1)strengthen land loading capacity and extend its service life.

2) convenient to construct ; reducing area , project cost and maintenance cost.

Introduction of Polyester Geogrid:

Polyester geogrid is a new kind of favorable earthwork base material to strength the road surface and roadbed, which composed of high strength polyester yarns coated with an inorganic sizing agent.

Features of Polyester Geogrid:

1) High tensile strength

2) High tear-resistant

3) Strong combination with gravel and soil

Application of Polyester Geogrid:

It mainly applied in strengthening soft ground of rail and road.

Sarah

- Q: How do geosynthetic meshes help in slope stabilization?

- Geosynthetic meshes provide reinforcement and stabilization to slopes by distributing the stresses and loads across a wider area, increasing the overall strength and stability of the slope. They prevent soil erosion and slippage, effectively reducing the risk of slope failure and landslides.

- Q: Are earthwork products suitable for use in riverbank stabilization projects?

- Yes, earthwork products are suitable for use in riverbank stabilization projects. These products, such as geotextiles and geogrids, provide reinforcement and erosion control to prevent the riverbank from collapsing and help maintain its stability. Additionally, earthwork products are designed to withstand water flow and provide long-lasting support, making them a viable solution for riverbank stabilization projects.

- Q: What are the long-term durability and lifespan of earthwork products?

- The long-term durability and lifespan of earthwork products can vary depending on various factors such as the quality of materials used, the construction techniques employed, and the level of maintenance provided. However, when properly designed, constructed, and maintained, earthwork products can have a substantial lifespan, often spanning several decades or even longer. Regular inspections, repairs, and necessary reinforcements can help ensure their durability and extend their lifespan.

- Q: What is the purpose of using geosynthetic reinforcements in retaining wall construction?

- The purpose of using geosynthetic reinforcements in retaining wall construction is to enhance the stability and performance of the wall by providing additional strength and resistance against soil pressures and potential failures. These synthetic materials, such as geotextiles or geogrids, are designed to distribute and transfer the load forces more efficiently, reducing the risk of wall displacement or collapse. They also help to control soil erosion and improve drainage, ensuring the long-term durability of the retaining wall structure.

- Q: How do geosynthetic clay liners aid in environmental protection?

- Geosynthetic clay liners (GCLs) aid in environmental protection by providing a highly effective barrier against the migration of pollutants. These liners are designed to prevent the leakage of contaminants, such as hazardous chemicals or landfill leachate, into the surrounding soil and groundwater. GCLs also contribute to the stability of engineered structures, such as landfills or containment ponds, reducing the risk of environmental damage. Additionally, these liners offer excellent hydraulic conductivity, which helps manage stormwater runoff and prevent erosion. Overall, geosynthetic clay liners play a crucial role in safeguarding the environment by preventing contamination and promoting sustainable waste management practices.

- Q: How are earthwork products used in construction projects?

- Earthwork products, such as sand, gravel, and soil, are essential in construction projects for various purposes. They are used as base materials for foundations, providing stability and support to structures. These products are also utilized for backfilling excavated areas, filling trenches, and creating embankments or berms for erosion control. Additionally, earthwork products are crucial in grading and leveling the construction site, ensuring proper drainage and preventing water accumulation. Overall, they play a fundamental role in the construction industry, serving as the building blocks for a solid and successful project.

- Q: What is the function of geosynthetic drainage materials in sports field construction?

- The function of geosynthetic drainage materials in sports field construction is to promote the effective and efficient removal of excess water from the field's surface and subsoil. These materials, such as geotextiles and geocomposites, are designed to provide superior drainage capabilities by facilitating the flow of water while preventing soil particles from clogging the system. This helps to maintain the stability and playability of the sports field by reducing the risks of water pooling, soil erosion, and turf damage caused by excessive moisture.

- Q: How are geonets used in earthwork?

- Geonets are used in earthwork as a geosynthetic material to provide reinforcement, drainage, and separation functions. They are commonly used in applications such as slope stabilization, erosion control, and road construction. Geonets help to increase the stability and load-bearing capacity of soil, prevent soil erosion, and improve drainage by allowing water to flow through them.

- Q: What are the key considerations when using geotextile tubes for shoreline stabilization?

- Some key considerations when using geotextile tubes for shoreline stabilization include the type and quality of the geotextile material used, the design and installation process, the site-specific conditions and requirements, and the long-term maintenance and monitoring. It is important to select a high-quality geotextile material that is durable, resistant to UV degradation and erosion, and has proper filtration properties. The design and installation process should take into account factors such as wave energy, tidal fluctuations, sediment transport, and site-specific constraints. Regular maintenance and monitoring should be conducted to ensure the effectiveness and stability of the shoreline stabilization system.

- Q: Can earthwork products be used for beach erosion control?

- Yes, earthwork products can be used for beach erosion control. These products, such as sandbags, geotextiles, and gabions, can help to stabilize and protect coastlines by preventing sediment loss, reducing wave energy, and promoting beach nourishment.

Send your message to us

Polyester/ Fiberglass Geogrid/ PP Biaxial Geogrid for Road Construction

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5000 m²

- Supply Capability:

- 1000000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords