High-Density Polyethylene Geogrids for Nutrition Geotextile Factory Manufacturer Used for Planting Grass

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5000 m²

- Supply Capability:

- 2000000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Nutrition geotextile in water environmental engineering .

Specification:

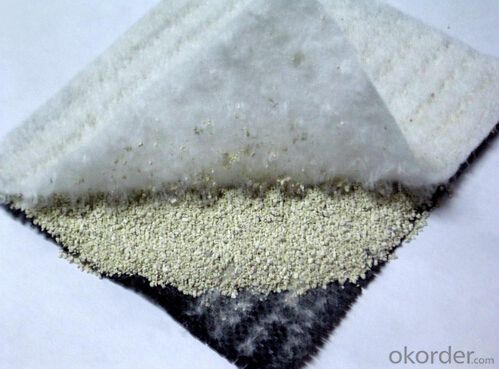

It is compound of one layer non woven geotextile and one layer animal plant fiber felt . After the decom position of plant fiber felt layer can enhance the penetration resistance of the plant cells , Animal glue protein fiber breakdown can be long-term nitrogen fertilizer for plant growth,

It is a kind of used for laying under the green concrete plate, the restoration of ecological products which help plants to grow.

Product Feature:

1. Simple and fast construction

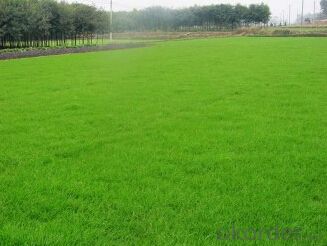

2. Achieve the greening effect quickly after construction

3. Due to the grass and composite fiber fabrics become into one integration, so it has the ability of certain degree of flow resistance for the water rising before the grass survive.

4. Composite fiber fabric is a continuous structure from slope top to slope toe, both ends are fixed, has high water flow resistance.

Technical Specification

5.0 m length and 1.05 m width. Reverse side all used filter material. Grass seeds: Bermuda grass (warm season grass), Bahia grass (warm season grass), Kentucky bluegrass (cold season grass), Tall fescue grass (cold season grass), Red fescue grass (cold season grass). Plant height: 0.1 ~ 0.5 m.

| NO. | Items | Specification | Notes | |||

| 1 | Total unit area weight g/sq.m | ≥380 | ||||

| 2 | dimension | width m | 1.0~2.0 | |||

| length m | as per user’s request | |||||

| 3 | Composite fiber fabrics | Material | Polyester Fiber | High strength PET | ||

| Unit area weight g/sq.m | ≥160 | |||||

| Mesh dimension mm | 8×8 | |||||

| Extension strengh kn/m | ≥11 | MD & CD | ||||

| 4 | Filtra layer | Material | Polyester non woven geotextile | |||

| Unit area weight g/sq.m | ≥40 | |||||

| 5 | Grass seeds, Fertilizer | Type | According to actual situation choose 3~5 grass seeds | |||

| Plant height m | 0.1~0.3 | |||||

| 6 | Fiber layer | Material | wood pulp cellulose | |||

| Unit areaweight g/sq.m | ≥15 | |||||

| 7 | flow resistance | ≥4 | not allow appear scour, suction and blanket turn-over etc. damage phenomenon | |||

| M/s | ||||||

| 8 | Anti-UV strengh conservation rate % | 65~80 | 3000hrs Continuously exposure 3000hrs | |||

| 9 | Supporting spare parts | ABS fastening nail | Material | ABS Resin | Fixed between two blankets by length direction | |

| Fiber diameter mm | 35 | |||||

| Nail length mm | 325 | |||||

| Lnail | Material | Steel wire (content 10% zinc-aluminium alloy) | Used to fix single blanket | |||

| Fiber diameter mm | 4 | |||||

| Nail length mm | 200 | |||||

| ABS connecting nail | Material | ABS Resin | Used in the slope between the two blankets ( width direction) | |||

| Nail length mm | 38 | |||||

| Connecting fiber | Material | High strength Polypropylene | Used in the slope between the two blankets ( width direction) | |||

| Length mm | Cut as per request | |||||

APPLICATION:

Generally laid on the river channel, slope protection etc. slope revetment projects, to control the water erosion, soil loss, meantime can reach the effect of slope ecological restoration and landscape greening, making river back to natural.

- Q: Can geogrids be used in temporary construction haul roads?

- Yes, geogrids can be used in temporary construction haul roads. Geogrids are commonly used to reinforce road bases and improve their load-bearing capacity. They can effectively distribute the load and prevent the formation of ruts and potholes, making them suitable for temporary haul roads during construction projects.

- Q: Can geogrids be used in mining applications?

- Yes, geogrids can be used in mining applications. Geogrids are a type of geosynthetic material that are commonly used in civil engineering and construction projects to reinforce soil and provide stability. In mining applications, geogrids can be used to strengthen and stabilize the ground, prevent soil erosion, and provide support to mining infrastructure such as haul roads and tailings dams. By improving the structural integrity of the ground, geogrids can contribute to safer and more efficient mining operations.

- Q: Are geogrids suitable for use in expansive soil conditions?

- Yes, geogrids are suitable for use in expansive soil conditions. Geogrids are commonly used in such conditions to improve the stability and strength of the soil. They help control soil movement, reduce cracking, and prevent damage to structures caused by expansive soils. Geogrids provide reinforcement and help distribute loads more evenly, making them an effective solution in expansive soil conditions.

- Q: Can geogrids be used in reinforcement of soft ground?

- Yes, geogrids can be used in the reinforcement of soft ground. Geogrids are commonly used to improve the stability and load-bearing capacity of weak or soft soil by distributing the applied loads and reducing settlement. They are effective in reinforcing soft ground and can provide increased strength and stability to the soil, making them a suitable solution for various civil engineering and construction projects.

- Q: How do geogrids improve the performance of geocell-reinforced slopes for erosion control?

- Geogrids improve the performance of geocell-reinforced slopes for erosion control by providing additional strength and stability. They help distribute the load evenly across the slope, preventing soil movement and reducing erosion. Additionally, geogrids increase the frictional resistance between soil layers, enhancing the overall slope stability and preventing soil slippage.

- Q: How many square meters of geogrid?

- Geogrid is a kind of main geosynthetics, which has unique properties and effects compared with other geosynthetics. Geogrid is often used as reinforcement of reinforced soil structure or composite material. The geogrid is composed of plastic geogrid, steel plastic geogrid, fiberglass geogrid and polyester warp knitted polyester geogrid

- Q: Can geogrids be used for reinforcement in railway tracks?

- Yes, geogrids can be used for reinforcement in railway tracks. Geogrids are a type of geosynthetic material that can provide additional strength and stability to the track structure. They can help distribute loads, prevent track settlement, and improve overall track performance.

- Q: Tgsg5050 what is the difference between Geogrid and gsz5050?

- Hello, "biaxial tensile plastic geogrid" is a general term, it can also be called two-way tensile polypropylene geogrid

- Q: What is the difference between a uniaxial and a biaxial geogrid?

- A uniaxial geogrid is designed to provide strength and stability in one direction, typically in the longitudinal axis. It is used to reinforce soil or other materials in applications such as road construction, retaining walls, and embankments. On the other hand, a biaxial geogrid is designed to provide strength and stability in both the longitudinal and transverse directions. It offers enhanced reinforcement capabilities and is commonly used in applications where multidirectional support is required, such as steep slopes, ground stabilization, and pavement systems.

- Q: What are the factors to consider in selecting a geogrid for a specific application?

- When selecting a geogrid for a specific application, there are several factors to consider. These include the type of soil and its properties, the expected loads and stresses on the geogrid, the desired design life and durability, the installation and construction methods, and any specific requirements or regulations for the project. Additionally, the cost and availability of the geogrid, as well as the supplier's reputation and technical support, should also be taken into account.

Send your message to us

High-Density Polyethylene Geogrids for Nutrition Geotextile Factory Manufacturer Used for Planting Grass

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5000 m²

- Supply Capability:

- 2000000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords