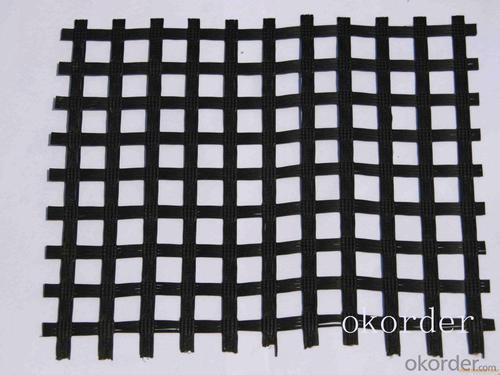

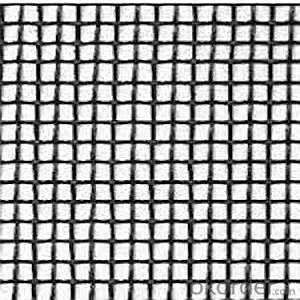

PP Fiberglass Geogrid Geocells for Road Construction with High Tensile Strength

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 1000000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Introduction

CNBM offers geogrids for base reinforcement. They are manufactured by welding or stitching together two layers of extruded, polypropylene, flexible geogrids to create a continuous sheet that will not separate.

Road bed reinforcement-it can effectively allocate and disperse load,improve the stability and load capacity of road bed and extend the useful lfe of road

1)fiberglass geogrid with CE certificate

2)Materials:fiberglass

3) Tensile strength:MD/CD:30 ~ 200kn/m

4)WIdth:1 ~ 6m

Our Service

Quality assurance

1.On a regular basis or as per your request,we entrust national testing agencies to conduct quality inspections

2. Strictly in accordance with the ISO9001-2008 international quality system standard,we monitor and manage the whole process throughout production,quality testing,and measurement to ensure product quality

3. For quality-related construction delay or substandard construction(except for damage or losses due to customer’s responsibility or irresistible natural disasters),we have refunding,replacement,and repair services.We will respond to customers’ feedbacks on quality issues within 24 hours.

Packaging & Shipping

Packing: PLASTIC FILM INSIDE, AND WOVEN BAG OUTSIDE

Shipping: About 15 days after receipt the deposit

FAQ:

Q: What kind of payments does jenor support?

A: T/T, L/C, Cash are accepted.

Q: Do you charge for the samples?

A: Accordeing to our company policy, the samples are free, we only charge the freight fee. And we will return the freight fee during the next order.

Q: Can you produce according to customers' design?

A: Sure, we are professional manufacturer, OEM and ODM are both welcome.

Q: Do you have other products?

A: Yes, please check the pictures:

- Q: What are the six main functions of Geosynthetics

- The special geotechnical synthetic material also includes the soil cushion, the earthwork net, the geogrid, the geocell, the geomembrane bag and the geotechnical foam.

- Q: Are geogrids suitable for use in vegetated slopes?

- Yes, geogrids are suitable for use in vegetated slopes. Geogrids provide reinforcement to the soil, helping to prevent erosion and improve stability in sloped areas. The open structure of geogrids allows for vegetation to grow through, promoting the establishment of plants and enhancing the overall aesthetics of the slope. Additionally, geogrids can help to distribute the load and reduce the stresses on the soil, thereby increasing the lifespan of the vegetated slope.

- Q: Bi directional plastic geogrid is suitable for engineering

- Wharf cargo yard and other permanent bearing foundation reinforcement.Supply geogrid.

- Q: What are the physical properties of Geosynthetics

- 2, the quality of unit area: the quality of the unit area of the unit area of geosynthetics. It reflects the properties of materials in many aspects, such as tensile strength, bursting strength and mechanical properties such as porosity, permeability and hydraulic performance, usually expressed as g / m2, is one of the important physical properties of geosynthetics. The quality of geotextile and geomembrane per unit area is affected by the density of raw materials, and the influence of thickness, admixture and water content. The commonly used geotextile fabric area quality is generally in the range of 50 ~ 1200g / m2

- Q: What are the specifications for geogrid installation?

- The specifications for geogrid installation typically include factors such as soil type, slope angle, required strength, and design considerations. It is important to follow manufacturer guidelines and industry standards to ensure proper installation, including techniques for anchoring, overlap, and tensioning. Additionally, proper site preparation, including soil compaction and leveling, is crucial for a successful geogrid installation.

- Q: What are the factors that affect the installation and survivability of geogrids in harsh environments?

- There are several factors that can impact the installation and survivability of geogrids in harsh environments. Firstly, the quality and strength of the geogrid material itself play a significant role. Geogrids made from durable and high-quality materials are more likely to withstand harsh conditions. Secondly, the installation technique is crucial, as improper installation can lead to geogrids being damaged or dislodged. The type and condition of the subgrade also affect the geogrid's survivability, as a stable and well-prepared subgrade provides a solid foundation for the geogrids. Additionally, environmental factors such as extreme temperatures, moisture levels, and chemical exposure can impact the long-term performance and durability of geogrids in harsh environments.

- Q: What materials are used to make geogrids?

- Geogrids are typically made from materials such as polyester, polyethylene, or polypropylene. These materials are chosen for their strength, durability, and resistance to environmental factors like UV radiation and chemical degradation.

- Q: What is the recommended geogrid junction spacing for specific applications?

- The recommended geogrid junction spacing for specific applications can vary depending on factors such as soil type, load requirements, and slope stability. It is important to consult engineering guidelines and specifications for each specific application to determine the appropriate geogrid junction spacing.

- Q: How do geogrids enhance the stability of steep fill slopes?

- Geogrids enhance the stability of steep fill slopes by providing reinforcement and reducing soil erosion. They act as a barrier, distributing the load more evenly across the slope and increasing the overall strength of the soil. This prevents the slope from sliding or collapsing under the weight of the fill material. Additionally, geogrids improve drainage and prevent water accumulation, which is crucial in maintaining slope stability.

- Q: Can geogrids be used in coastal erosion control?

- Yes, geogrids can be used in coastal erosion control. Geogrids are often employed as a reinforcement material to stabilize soil and prevent erosion in coastal areas. They can be used to strengthen slopes, retain beach or dune materials, and provide stability to coastal structures like seawalls or revetments. Geogrids are designed to withstand the harsh coastal environment and can effectively reduce the impact of wave and tidal action on the shoreline, making them a valuable tool in coastal erosion control efforts.

Send your message to us

PP Fiberglass Geogrid Geocells for Road Construction with High Tensile Strength

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 1000000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords