Tencate Mirafi Geogrids Plastic Grass Paving Grid / Plastic Parking Grass Grid / Parking Grass Grid Manufacturer

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m

- Supply Capability:

- 50000 m/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Quick Details

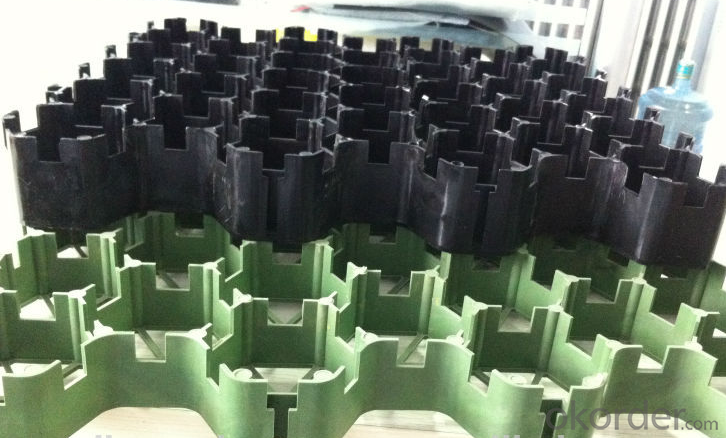

| Type: | Geogrids,Geomembranes | Place of Origin: | Shandong China (Mainland) | Brand Name: | Cmax |

| Model Number: | 001 | material: | HDPE | color: | green/black |

| certification: | CE /ISO9001 |

Packaging & Delivery

| Packaging Detail: | regular package or at requested |

| Delivery Detail: | within 7 days afetr advanced pament is received |

Specifications

Plastic grass grid:

1). completely greening

2) save investment

3) smooth surface

4) high strength

Plastic grass grid:

Plastic grass grid specifications:

make grass lawn and carprk two-in -one

HDPE materail, eco-friendly

proof pressure, wear- resisting, shock resistance,

Plastic grass grid Types:

hexagonal grass paver and circular grass paver

Height: 3.8cm, 5cm, 7cm

APPLICATIONS

Parking Lots (Grass or Gravel) & Overflow Parking

Overflow grass car & bus parking lots

Grass parking areas

Fire Truck Access routes / Fire Lanes

Helipads / Helicopter landing pads

Grassed light aircraft / airplane transport areas / taxiways

Handicap access routes

Golf cart paths

Emergency access roads

Residential access and parking spaces

Grass Driveway and grass shoulders

Polymer Density | High Density Polyethylene with density of 0.935 - 0.965 g/cm3 ASTM D 1505 |

Environmental Stress Crack Resistance | > 4000 hours ASTM D 1693 |

Carbon Black Content | Carbon black content 1.5% - 2.0% ASTM D 1603 |

Sheet Thickness | Smooth:1.1mm,1.2mm,textured:1.5mm ,1.7mm ASTM D 5199 |

Cell Details | welding distance:330-1000mm |

Cell Depth | 50-250mm |

Seam Peel Strength | As per US Army Corps of Engineer's Report GL-86-19 Appendix A |

Seam Hang Strength | A 100mm wide seam sample supports a 72.5 kg load for a minimum of 30 days in an ambient room temperature environment. |

Certification | CE ,ISO |

Classification | 1. smooth surface without hole 2. smooth surface with hole 3. textured surface with hole 4. textured surface without hole |

Plastic grass grid Characteristics:

1). completely greening

2) save investment

3) smooth surface

4) high strength, long service life

- Q: What are the factors that influence the design and selection of geogrids for reinforcement?

- There are several factors that influence the design and selection of geogrids for reinforcement. These include the type and characteristics of the soil, the specific application or project requirements, the anticipated loads or stresses on the geogrid, the desired design life and durability, and cost considerations. Additionally, factors such as installation conditions, site constraints, and environmental conditions may also play a role in determining the appropriate geogrid design and selection.

- Q: How do geogrids improve the performance of flexible pavements?

- Geogrids improve the performance of flexible pavements by enhancing their structural integrity and overall stability. They act as reinforcement materials, distributing the load and reducing the stresses on the pavement layers. This helps to prevent the formation of cracks, rutting, and other forms of pavement distress, ultimately extending the lifespan of the pavement.

- Q: How do geogrids improve the load transfer in road pavements?

- Geogrids improve the load transfer in road pavements by enhancing the stability and strength of the base and subgrade layers. They distribute the load more evenly, reducing the stress on the pavement structure. Additionally, geogrids prevent the lateral movement of soil particles, improving the overall performance and lifespan of the road.

- Q: The difference between composite geomembrane and bentonite waterproof blanket

- Different waterproof performance. Composite geomembrane: composite geomembrane composite impermeable membrane is divided into one cloth and two membrane. Tensile, tearing resistance, bursting and other physical and mechanical properties of high index, the product has high strength, good elongation, deformation modulus, acid and alkali resistance, corrosion resistance, aging resistance, good performance of seepage control, etc..

- Q: What is the typical geogrid roll length for specific applications?

- The typical geogrid roll length for specific applications can vary depending on the project requirements and the specific type of geogrid being used. However, common geogrid roll lengths range from 50 to 500 feet, with some specialty products available in longer lengths.

- Q: EG65R type geogrid meaningWhat is the meaning of EG, said 65 per meter of tensile strength is 65kN? 65KN/m R will be broken? What is the meaning?

- Is that tension can reach more than 65KN, as can pull off in what, I do not know, if there is a need to contact me, thank you, hope to adopt!

- Q: Geogrid is mainly used for what?

- Application of unidirectional geogrid:Unidirectional geogrid is a kind of high strength structural material, which is suitable for highway, municipal road, railway, runway and so on. 1, strengthen the embankment, can effectively improve the load distribution, and the bearing capacity and service life of the subgrade stability; 2, preventing the material loss caused by the deformation of subgrade, and even rupture; 3, can withstand greater load; 4, applicable to all kinds of soil, no place to be drawn, saves time and labor; and the use of construction simple biaxial geogrid:

- Q: In the middle of geogrid foundation treatment process is belongs to the concealed work it

- After the completion of the project is not visible to the process or project site, are known as the hidden works, so the geogrid must belong to the hidden works

- Q: How do geogrids help in reducing the need for excavation and grading?

- Geogrids help in reducing the need for excavation and grading by providing reinforcement and stabilization to the soil. They are typically installed within the soil layers to enhance its strength and prevent erosion. By distributing the load and increasing the bearing capacity of the soil, geogrids minimize the requirements for extensive excavation and grading, saving time and costs in construction projects.

- Q: Can geogrids be used in coastal protection?

- Yes, geogrids can be used in coastal protection. Geogrids are commonly used in coastal engineering projects to stabilize and reinforce soil or rock structures, such as seawalls, revetments, and breakwaters. They help to prevent erosion and provide extra strength and stability to withstand the forces of waves, tides, and storms. Geogrids are effective in enhancing coastal protection measures and can be a valuable component of coastal engineering solutions.

Send your message to us

Tencate Mirafi Geogrids Plastic Grass Paving Grid / Plastic Parking Grass Grid / Parking Grass Grid Manufacturer

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m

- Supply Capability:

- 50000 m/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords