Auto climbing formwork , bridge climbing form Cantilever Formwork

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 set

- Supply Capability:

- 10000 set/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Place of Origin: | Beijing, China (Mainland) |

Brand Name: | ZULIN |

Model Number: | ZPM-100 |

Certification: | ISO9001-2008 |

Minimum Order Quantity: | One 20ft container |

Price: | Negotiate |

Packaging Details: | in bulk ,pallet ,bundle or according the customer demand |

Delivery Time: | after deposit 15-20 days |

Payment Terms: | T/T L/C (bank transfer) |

Supply Ability: | 100sets/day |

Descrition:

Introduction

The lifting power of Auto-climbing Formwork System ZPM-100 comes from the hydraulic system, which includes the oil cylinder and commutator. The steel rail and the bracket can climb alternately, and therefore the whole formwork system climbs steadily. Cranes are not needed during the construction. It’s easy to operate,highly active and safe. It’s the best choice for construction of high buildings and towers.

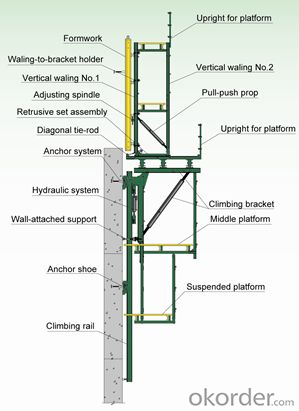

ZPM-100 Structure Sketch

The Characteristics

1 The system is able to climb as a whole or individually, and in a stable way.

2 As the system climbs by itself and cleaning work is done in situ, tower crane lifts are greatly reduced.

3 It’s safe and convenient to operate, and labor and material costs will be greatly slashed.

4 The bracket will not come back to the ground until the construction is finished. Field spacing will be reduced and the bumping damages can be almost prevented, especially for the panels.

5 The climbing process is steady, synchronous and safe.

6 All-purpose platforms are provided, and there is no need to set up additional operation platforms, which means saving the labor and material costs again.

7 There is little margin for error. And if there is, it is simple and easy to correct. Deviations of construction work can be eliminated floor by floor.

8 Fast climbing speed can be achieved, and the construction cycle will be maintained according to schedule.

- Q: What are the maintenance and maintenance of hydraulic climbing formwork

- Regular inspection of the climbing device should check the connections. In particular, the following parts of the site to focus on inspection and reinforcement: according to the design requirements of the bolt with spring washers

- Q: Climbing frame is divided into several kinds, what is its running mode? What is the rental cost? Please explain in detail! Thank you very much

- Install the lifting seat and a guide seat is connected with the high wall, main frame vertical rod, the frame set up to the designed height, laying the top scaffold, block feet - laying bottom safety nets and scaffolding, making turning plate - the upper part of the frame body structure and effective tie (tie spacing is not greater than 6m) - display efflux dense mesh safety net to the top of the shelf, the anti dropping boom is inserted into the base anti dropping device, the installation of steel rope - placed distribution cables, installation control cabinet, electric hoist, electric wiring and debugging system, pre inspection, electric hoist, demolition of frame body and the upper structure of pulling and synchronization a layer - installation completed, enter the upgrade cycle

- Q: The difference between the scaffold and the scaffold

- The difference between climbing frame and scaffolding is commonly used scaffolding from below has been set up, which is followed by building up climbing frame, the figure is upstairs, they have in common is that we are like scaffolding

- Q: Advantages and disadvantages of climbing frame and floor type scaffold

- Advantages and disadvantages of climbing frame and floor type scaffoldPjal | browse 5789Recommended 2016-09-21 09:11:21 best answerClimbing frame, also known as the lifting frame, according to its source of power can be divided into hydraulic, electric, manual pull and other major categories. It is a new type of scaffolding system developed in recent years, which is mainly used in high-rise shear wall construction. It can climb up or down the building. This system makes the change scaffolding Technology: one is without turning over the shelf; two is exempt from the disassembly process of scaffold (an assembly has been used after the completion of construction, and not affected) building height restrictions, greatly saves manpower and material. And in terms of security is also a big change for the traditional scaffolding. Highly developed in high-rise buildings. But it also has the disadvantage of fixed structure.

- Q: The whole concrete wall climbing frame or good use of steel scaffolding

- Climbing frame, also known as the lifting frame, according to its source of power can be divided into hydraulic, electric, manual pull and other major categories. It is a new type of scaffolding system developed in recent years, which is mainly used in high-rise shear wall construction

- Q: What is an integrated climbing frame? What are the works? What are the advantages

- . It can climb up or down the building. This system makes the change scaffolding Technology: one is without turning over the shelf; two is exempt from the disassembly process of scaffold (an assembly has been used after the completion of construction, and not affected) building height restrictions, greatly saves manpower and material

Send your message to us

Auto climbing formwork , bridge climbing form Cantilever Formwork

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 set

- Supply Capability:

- 10000 set/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords