Hydraulic Climbing Formwork and Cantilever Formwork

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Hydraulic Climbing Formwork and Cantilever Formwork

Product Introduction and Application:

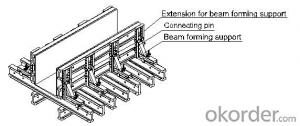

Auto-climbing Formwork is an advanced formwork system used for high-rise building construction or towering cast-in-place reinforced concrete structure construction. It is a hydraulic system firmly attached to the building. After the first pouring, it fixes anchor shoes on the finished wall, lifts the brackets and formwork to the right position, matches the formwork and realize fastening and cycle construction by using machinery equipment and support system.

Features:

①Fast construction, easy operation, good quality and low cost.

②The steel rail and the bracket alternately lifted by hydraulic ram to achieve the whole formwork climb up, which makes the whole formwork system climb steadily.

Projects:

Xiangwang Big Bridge in Huaibei,Anhui Province

- Q: How is the hydraulic support moving

- Hydraulic support shift method: push the jack extension, push the rod out, push the scraper conveyor forward a step, and then move the jack close, push the lever to take back, scraper conveyor reaction on the bracket, driving the stent forward a step Distance, complete hydraulic support shift frame.

- Q: Climbing and floor scaffolding advantages and disadvantages

- The bolt tightening torque should not be less than 40N · m, and should not be greater than 65N · m; [1] 2) The bar at the node is eccentric, 3) The connection quality of the fastener joints is significantly affected by the quality of the fastener itself and the operation of the workers. (3) The connection quality of the fastener joints is significant.

- Q: What is a climbing frame?

- Climbing frame, also known as attached lift scaffolding, the equipment and equipment is the rapid development of the beginning of this century, a new scaffolding technology, construction technology in China has an important impact. It will be high operations into a low operation, the floating operations into the frame internal operations, with significant low-carbon, high-tech content and more economical, more secure, more convenient and so on.

- Q: Is the scaffolding scaffolding?

- This system makes the scaffolding technology completely changed: one is not to turn the shelf, the second is to remove the scaffolding of the dismantling process (after assembly has been used to complete the construction), and not subject to height restrictions on the building, a great savings in manpower And material. And in the security point of view for the traditional scaffolding has a greater improvement. In the high-rise buildings with great development advantages.

- Q: Climbing several, how is it running? And how much is the rental fee? Please explain in detail master! Thank you!

- Set the mounting platform --- Place the base, install the rails, assemble the horizontal truss parts - connect the beams to the rails with bolts and fasten the main frame to the beams - On the beam - the installation of wall-mounted device, the frame unloading to the guide seat --- with the structure connected to the elevated body, erected scaffolding, laying the middle layer or temporary scaffolding --- and the building structure to do temporary frame Pull the connection, hanging out the top of the safety net --- installed after the third beam, the installation of lifting seat and a layer with a wall guide block --- then the main frame of the main frame, the frame erected to the design height, Laying the top scaffolding plate, foot plate --- laying the bottom of the safety net and scaffolding, the production of flap - the upper frame and the structure of the effective pull-pull (pull-pull spacing of not more than 6m) --- hanging outside the row of dense security To the top of the frame --- the anti-fall boom inserted into the base anti-fall device, install the lifting wire rope --- placed electric control cabinet, distribution cable, install electric hoist, wiring, commissioning electrical system --- preload electric gourd, inspection and acceptance, with removal of the upper frame structure then pull, lift one synchronization --- fully installed, into Upgrade cycle

- Q: The difference between climbing and sliding mode

- The main difference between climbing and sliding mode (simple distinction, see below for details): Slipform: Increases the overall scale of the mold and the concrete in contact with each other. When the sliding mold is raised, the concrete in the upper part of the template is just under water, and the concrete in the lower part is near the initial condensed state, and the strength of the concrete is only 0.2 ~ 0.4Mpa. Climbing mode: the rise, the template has been off the concrete, then the concrete strength is greater than 1.2Mpa, the template is not friction with the concrete. Detailed distinction: Slip mode: cement concrete pouring used in a template, it can be along the horizontal direction, the slope direction or vertical direction gradually sliding, so that the side of the paused, side stripping, is an economical and advanced method, Known as sliding mode construction. The concrete used is hard thick concrete, or when the template slips, the edges of the concrete are prone to collapse. High-rise buildings, if the site stacking conditions are limited, the use of sliding mode is better, and the construction speed, reduce the template loss rate. But for the special wall of the building is not suitable for more. Climbing template: climbing template is attached to the building structure, with the structure of the construction and layer by layer of a template, when the structure of concrete to achieve demoulding strength and stripping, the template does not fall, relying on mechanical equipment and support the template And climbing up the device to climb up a layer, positioning fastening, repeated cycle construction. Climbing is an advanced template construction technology for cast-in-place reinforced concrete structures for high-rise buildings or towering structures.

Send your message to us

Hydraulic Climbing Formwork and Cantilever Formwork

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords