Series of Formwok from China

- Loading Port:

- XINGANG

- Payment Terms:

- TT or L/C

- Min Order Qty:

- 100 Meter/Meters m

- Supply Capability:

- 6000 Meter/Meters per Month m/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Timber-Beam Formwork

1.Introduction of Timber-Beam Formwork

H20 beam

High-grade raw materials;

High quality, low price;

Dimensional stability.

H20 Timber Beam

Wings:Spruce Wood(From Finland);Web:Cottonwood plywood;Glue:HENKEL Glue

2.Specifications of the Series of Formwork

Wood material:Spruce from Finland

Flange size: 80X 40mm

Web width: 30mm (3-layer OR multi-layer)

Weight/: 5.00kg-5.20kg/meter

Length avaible:1.25/2.45/2.65/2.9/3.3/3.6/3.9/4.9/5.9/6.6 Meter

Quality assure: Have been applied to all over the world

Surface finishing: Waterproof yellow painting or other color

Packing: Different length loaded differently

Glue:HENKEL

Price advantage: 20-30% cheaper than others based on same quality

Design ability: We can offer you a general proposal based on your structural drawings

3.Characteristics of the Series of Formwork:

Standardized production lines.

Professional loading.

Supply capability:3000Meter/day.

L max=6600MM.

Production lines

Professional loading

Finger jointing of the flange and web,the strength of timber beam is highly improved.

Max. shearing force failure load:40KN

Well treated to prevent from water penetration or erosion, so the service life is maximally

extended.

Normally, CNBM timber beam H20 can be used for 4 to 5 years,the exact using time would

depend on maintenance & storage.

Robust caps at the end of the girders protect against damages.

H20 timber beam with end protection

4.Project Application

Pearl Tower 14B,Doha,Qatar

Steel Frame Formwork

1.Introduction of Steel Frame Formwork

As the framework,it is adapted to the plywood with thickness of 18mm.High-precision production

line guarantees the perfect products.It can be used for wall,column and corewall.

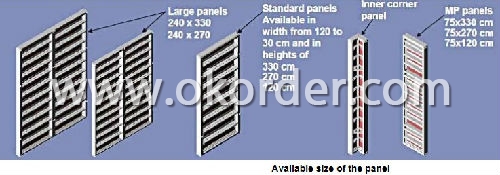

2.Characteristics of Steel Frame Formwork

Few parts for fast forming.

Max.Concrete pressure:80KN/M2

Hot-dip galvanized steel frame

The thickness of plywood is 18MM & the panel is 14CM

Compatibility with Hunnebeck Manto system due to similar edge profile.

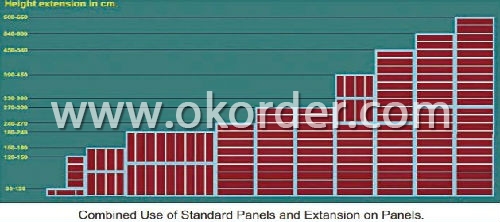

Flexible Panel arrangement and height extension.

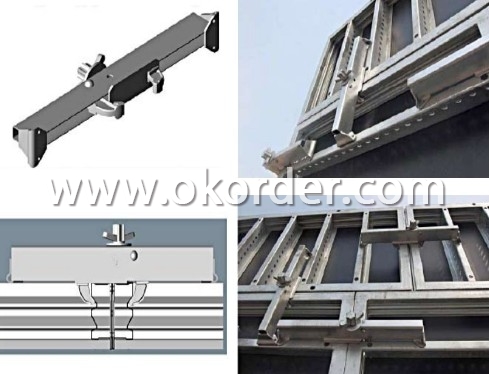

3.System Details & Application of Steel Frame Formwork

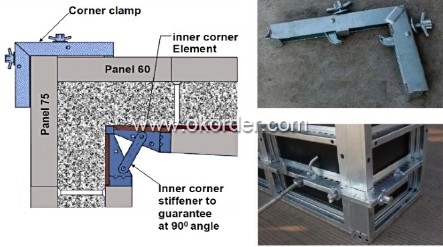

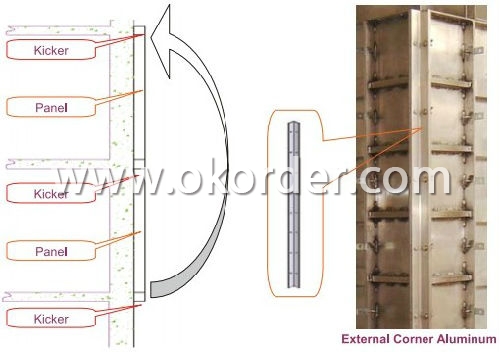

Corner Details

4.Project Application of Steel Frame Formwork

Aluminum Formwork

1.Introduction of Aluminum Formwork

Whole aluminum formwork is a new technology for formwork,It is very light and the concrete

surface is more smooth than traditional method.All the material is recyclable.

2.Characteristics of Aluminum Formwork

Lighter weight but high bearing capacity.

Manual transportation can be achieved,greatly reduces the aggregate cost.

Perfect design,excellent produce and well welding make sure the flatness of concrete surface.

It is with the advantages of standard design,excellent applicability and interchangeable.

Simple,safe and fast.

No rust corrosion,easy maintenance,and high turnover rate.

The formwork series are a complete system with a full set of accessories,can be set up flexibly

according to project.

3.Details of Aluminum Formwork

4.Application of Aluminum Formwork

- Q: What are the maintenance and maintenance of hydraulic climbing formwork

- Regular inspection of the climbing device should check the connections. In particular, the following parts of the site to focus on inspection and reinforcement: according to the design requirements of the bolt with spring washers

- Q: Climbing frame is divided into several kinds, what is its running mode? What is the rental cost? Please explain in detail! Thank you very much

- Install the lifting seat and a guide seat is connected with the high wall, main frame vertical rod, the frame set up to the designed height, laying the top scaffold, block feet - laying bottom safety nets and scaffolding, making turning plate - the upper part of the frame body structure and effective tie (tie spacing is not greater than 6m) - display efflux dense mesh safety net to the top of the shelf, the anti dropping boom is inserted into the base anti dropping device, the installation of steel rope - placed distribution cables, installation control cabinet, electric hoist, electric wiring and debugging system, pre inspection, electric hoist, demolition of frame body and the upper structure of pulling and synchronization a layer - installation completed, enter the upgrade cycle

- Q: The difference between the scaffold and the scaffold

- The difference between climbing frame and scaffolding is commonly used scaffolding from below has been set up, which is followed by building up climbing frame, the figure is upstairs, they have in common is that we are like scaffolding

- Q: Advantages and disadvantages of climbing frame and floor type scaffold

- Advantages and disadvantages of climbing frame and floor type scaffoldPjal | browse 5789Recommended 2016-09-21 09:11:21 best answerClimbing frame, also known as the lifting frame, according to its source of power can be divided into hydraulic, electric, manual pull and other major categories. It is a new type of scaffolding system developed in recent years, which is mainly used in high-rise shear wall construction. It can climb up or down the building. This system makes the change scaffolding Technology: one is without turning over the shelf; two is exempt from the disassembly process of scaffold (an assembly has been used after the completion of construction, and not affected) building height restrictions, greatly saves manpower and material. And in terms of security is also a big change for the traditional scaffolding. Highly developed in high-rise buildings. But it also has the disadvantage of fixed structure.

- Q: The whole concrete wall climbing frame or good use of steel scaffolding

- Floor scaffold:Advantage:1) large bearing capacity. When the scaffolding geometry and structure comply with the relevant requirements, under normal circumstances, the bearing capacity of 15kN ~ 35kN of the single column scaffold (1.5tf ~ 3.5tf, design value).Clamp and Tube Scaffold2) easy to install and disassemble, set up flexible. Because the length of the steel tube is easy to adjust and the fastener is convenient to connect, the utility model can be used for various buildings and structures with various planes and elevations.3, compared with the economy, the processing is simple, and the investment cost is low; if the geometric dimensions of the scaffold are carefully designed, and the utilization rate of the steel tube is improved, the material consumption can also obtain better economic effect. Fastener steel pipe frame equivalent to 15 square meters per square meter of construction steel.

- Q: What is an integrated climbing frame? What are the works? What are the advantages

- . It can climb up or down the building. This system makes the change scaffolding Technology: one is without turning over the shelf; two is exempt from the disassembly process of scaffold (an assembly has been used after the completion of construction, and not affected) building height restrictions, greatly saves manpower and material

1. Manufacturer Overview

| Location | Shanghai,China |

| Year Established | 1949 |

| Annual Output Value | Below US$1 Million |

| Main Markets | North America South America Eastern Europe Southeast Asia Africa Oceania Mid East Eastern Asia Western Europe Central America Northern Europe Southern Europe South Asia Domestic Market |

| Company Certifications | ISO 9001:2008 |

2. Manufacturer Certificates

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period |

3. Manufacturer Capability

| a) Trade Capacity | |

| Nearest Port | SHANGHAI |

| Export Percentage | 91% - 100% |

| No.of Employees in Trade Department | 200 |

| Language Spoken: | English,Chinese |

| b) Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Series of Formwok from China

- Loading Port:

- XINGANG

- Payment Terms:

- TT or L/C

- Min Order Qty:

- 100 Meter/Meters m

- Supply Capability:

- 6000 Meter/Meters per Month m/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches