Climbing Formwork- Formwork- Cantilever

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

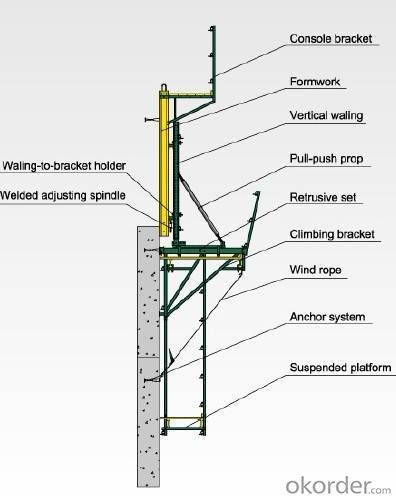

CantileverFormwork is mainly used in the concrete pouring of pier,high buildings, and so on. The concrete lateral pressure is entirely supportedby anchor system and the wall-through tie-rods, additional reinforcement is notneeded. The construction is easy, rapid and economical. A single pouring height is high and thefinished concrete surface is perfect. Cantilever formwork has several types,thestructure is similar, and has its own different characteristic.Canuse them according to actual demand.

Maincantilever Formwork:PJ200 & PJ240,CB-240 etc.

Anchor system

Anchor system is the most importantsupporting part. The system is made of five parts shown below. There into,tensile bolt, anchor shoe and bowl-climbing cone can be taken out for reusingafter the concrete pouring

① Tensile bolt M30/L= 110

② Anchor shoe

③ Bowl-climbing cone M30/D15

④ High-strength rod D15

⑤ Ancor plate D15

- Q: How do steel props compare to telescopic props in terms of performance?

- Steel props and telescopic props are both commonly used in construction projects for providing temporary support to structures. In terms of performance, steel props are known for their exceptional load-bearing capacity, stability, and durability. They are typically made of high-quality steel, making them suitable for heavy-duty applications. On the other hand, telescopic props offer the advantage of adjustability, allowing for easy height modification and precise positioning. However, they may have a lower load-bearing capacity compared to steel props. Overall, the choice between steel props and telescopic props depends on the specific requirements of the project, with steel props being more suitable for heavy loads and telescopic props being ideal for flexible and adjustable support.

- Q: How is a steel prop different from other types of supports?

- A steel prop is different from other types of supports primarily because it is made of durable and sturdy steel material, which provides excellent strength and stability. Unlike wooden or plastic supports, a steel prop can withstand heavy loads and is resistant to wear and tear. Additionally, steel props are adjustable, allowing for easy height modifications to suit different construction needs.

- Q: Can steel props be used for supporting temporary military structures?

- Yes, steel props can be used for supporting temporary military structures. Steel props, also known as adjustable steel props or steel shore props, are commonly used in construction to support temporary structures such as formwork, scaffolding, and shoring systems. These props are made of high-grade steel, which provides strength, stability, and durability. In the military context, temporary structures are often erected for various purposes, including command centers, field hospitals, barracks, and storage facilities. Steel props can be an ideal choice for supporting these structures due to their load-bearing capacity and adjustability. Steel props can support heavy loads and can be easily adjusted to the desired height. They can be extended or retracted according to the specific requirements of the military structure. This adjustability feature allows for flexibility in adapting to different terrain or ground conditions, ensuring stability and safety. Furthermore, steel props are relatively lightweight and easy to transport, making them suitable for military operations where mobility is crucial. They can be quickly assembled and disassembled, allowing for efficient deployment and relocation of temporary structures as needed. Additionally, steel props are resistant to corrosion and adverse environmental conditions, making them suitable for military deployments in various climates and terrains. They can withstand harsh weather conditions such as strong winds, heavy rain, and extreme temperatures. In conclusion, steel props can indeed be used for supporting temporary military structures. Their strength, adjustability, mobility, and resistance to environmental factors make them a reliable choice for providing the necessary support and stability required in military operations.

- Q: How do steel props contribute to the prevention of structural deformations?

- Steel props, also referred to as adjustable steel posts or shores, are of utmost importance in construction projects as they play a vital role in averting structural distortions. They contribute to the overall stability and safety of structures through the provision of temporary support during various construction stages. The primary manner in which steel props assist in the prevention of structural deformations is by shouldering the structure's load. During construction, steel props are strategically positioned to bear the weight of floors, walls, beams, or any other structural component that may be under construction or in need of reinforcement. By equally distributing the load, steel props assist in mitigating excessive stress on individual structural elements, thereby diminishing the risk of deformations. Moreover, the adjustability feature of steel props allows for precise positioning and alignment. This adaptability empowers construction workers to ensure that the structure remains level and plumb throughout the construction process. By preserving the correct alignment, steel props help forestall any tilting or leaning that could potentially lead to structural deformations. Another significant contribution of steel props is their capacity to absorb and distribute lateral forces. During construction, structures are subjected to diverse external forces, such as wind loads or seismic activity. Steel props assist in counterbalancing these lateral forces by providing supplementary support and stability. By resisting the lateral forces, steel props impede structural deformations, such as excessive sway or deflection. Additionally, steel props serve as temporary supports that aid in maintaining the integrity of the structure until permanent load-bearing elements, such as columns or beams, are installed. These temporary supports guarantee that the structure remains stable and secure during construction, thereby diminishing the risk of deformations or collapses. In conclusion, steel props contribute to the prevention of structural deformations by shouldering the structure's load, preserving proper alignment, absorbing and distributing lateral forces, and providing temporary support. Their role in construction projects is indispensable in ensuring the stability, safety, and longevity of structures.

- Q: Are steel props adjustable in angle?

- No, steel props are not adjustable in angle. Steel props are vertical supports used in construction to provide temporary support to beams, walls, and ceilings during construction or renovation. They are designed to be adjusted in height to accommodate different levels, but their angle remains fixed.

- Q: Are steel props resistant to extreme weather conditions?

- Yes, steel props are generally resistant to extreme weather conditions. Steel is known for its strength and durability, which makes it highly resistant to various weather elements. It can withstand high winds, heavy rain, snow, and extreme temperatures without getting damaged or deteriorating. Additionally, steel props are often coated with protective finishes such as galvanization or powder coating, which further enhance their resistance to rust and corrosion caused by harsh weather conditions. Therefore, steel props are a reliable choice for construction projects in areas prone to extreme weather.

- Q: How do you properly set up a steel prop?

- Setting up a steel prop properly involves a few key steps to ensure stability and safety. Here is a guide on how to properly set up a steel prop: 1. Assess the load-bearing requirements: Before setting up a steel prop, it's essential to evaluate the weight and load it will be supporting. This will help you determine the appropriate prop size and capacity needed for the job. 2. Choose the right prop: Select a steel prop that meets the load-bearing requirements as determined in step one. Consider factors such as prop height adjustment range, weight capacity, and overall durability. 3. Prepare the area: Clear the area where the steel prop will be set up from any debris, obstacles, or loose materials that could compromise stability. Ensure the ground is level and solid to provide a sturdy foundation. 4. Extend the prop: Extend the steel prop to the desired height by turning the adjustment collar. Ensure the collar is tightened securely to prevent accidental retraction during use. 5. Position the prop: Place the steel prop at the desired location, ensuring it is perpendicular to the ground and aligned with the load-bearing point. If necessary, use a spirit level to check for vertical alignment. 6. Secure the prop: Once the prop is positioned correctly, secure it in place. This can be done by using adjustable steel plates or timber needles to provide additional support and prevent movement. 7. Inspect for stability: Check the prop's stability by gently applying pressure to ensure it can bear the anticipated load. If any instability is detected, adjust the prop's height or reposition it until it is secure. 8. Regularly monitor and maintain: Throughout the project duration, it is crucial to monitor the steel prop's stability regularly. Inspect for any signs of wear, damage, or shifting and address any issues immediately. Additionally, avoid overloading the prop beyond its recommended capacity. Remember, setting up a steel prop properly is essential not only for the success of the project but also for the safety of workers and the surrounding environment. Always follow manufacturer guidelines and local regulations when working with steel props to ensure a secure and stable setup.

- Q: Can steel props be used on uneven surfaces?

- Yes, steel props can be used on uneven surfaces. Steel props are adjustable and can be extended or shortened to fit various heights and angles. This flexibility allows them to be used on uneven surfaces by adjusting the length of the props accordingly.

- Q: Are steel props suitable for use in underground utility tunnel construction?

- Indeed, underground utility tunnel construction can benefit from the use of steel props. These props, alternatively referred to as steel shoring or steel supports, are commonly employed in construction projects to provide temporary support to structures or excavations. They possess the ability to withstand heavy loads and ensure stability across a range of applications, including underground tunnels. There are numerous advantages to utilizing steel props in underground utility tunnel construction. Firstly, they exhibit strength and durability, enabling them to bear the weight of the tunnel as well as any additional loads such as utilities or equipment. Their adjustable nature allows for flexibility throughout the construction process, accommodating different heights and lengths as needed. Furthermore, steel props are characterized by their ease of installation and removal, rendering them ideal for temporary applications. They can be swiftly assembled and disassembled, contributing to a reduction in construction time and costs. Additionally, steel props can be repurposed in other projects, making them a cost-effective long-term solution. In terms of safety, steel props provide a stable and secure support system for workers and equipment during tunnel construction. They are specifically designed to endure lateral forces and mitigate the risk of collapse or accidents. This prioritizes the safety of workers while also safeguarding the tunnel and utilities against potential damage. In summary, steel props prove to be a fitting choice for underground utility tunnel construction. They offer strength, durability, flexibility, and safety, making them an effective solution for supporting the excavation and construction of tunnels.

- Q: Can steel props be used in underground construction projects?

- Steel props have the capability to be utilized in underground construction projects. These props, also referred to as steel shores or steel acrow props, consist of adjustable steel tubes that are employed to provide support for temporary structures while construction is underway. They are commonly employed in a variety of construction projects, including those that occur underground. In underground construction endeavors, steel props are frequently implemented to offer support for temporary structures such as formwork, scaffolding, or falsework that are necessary during the construction process. These props are responsible for supplying vertical support and aiding in the distribution of weight from the structure above to the ground below. Steel props possess a sturdy and durable nature, and they possess exceptional load-bearing capabilities, rendering them suitable for underground construction projects. They can be effortlessly adjusted to achieve the desired height and offer dependable support throughout the entirety of the construction process. Additionally, steel props are adaptable and can be utilized in various soil conditions, including those that feature soft or unstable ground. Furthermore, steel props are known for their simplicity of installation and removal, which proves advantageous in underground construction scenarios where space and access may be limited. They can be promptly adjusted and securely positioned, enabling efficient progress to be made during the construction process. In conclusion, steel props are widely employed and serve as an effective solution for providing support in underground construction projects. Their strength, versatility, and adjustability make them a reliable choice for ensuring the safety and stability of temporary structures throughout the construction process.

Send your message to us

Climbing Formwork- Formwork- Cantilever

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords