Climbing Formwork- Cantilever Formwork

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

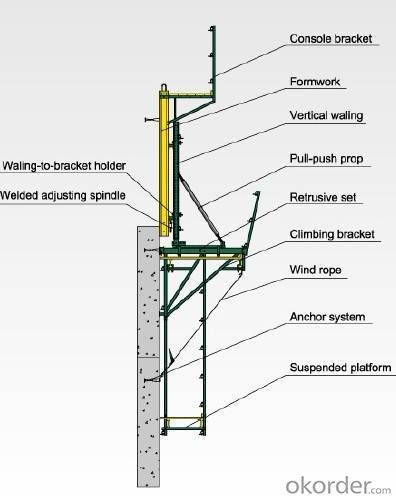

CantileverFormwork is mainly used in the concrete pouring of pier,high buildings, and so on. The concrete lateral pressure is entirely supportedby anchor system and the wall-through tie-rods, additional reinforcement is notneeded. The construction is easy, rapid and economical. A single pouring height is high and thefinished concrete surface is perfect. Cantilever formwork has several types,thestructure is similar, and has its own different characteristic.Canuse them according to actual demand.

Maincantilever Formwork:PJ200 & PJ240,CB-240 etc.

Anchor system

Anchor system is the most importantsupporting part. The system is made of five parts shown below. There into,tensile bolt, anchor shoe and bowl-climbing cone can be taken out for reusingafter the concrete pouring

① Tensile bolt M30/L= 110

② Anchor shoe

③ Bowl-climbing cone M30/D15

④ High-strength rod D15

⑤ Ancor plate D15

- Q: Can steel props be used in commercial building construction?

- Commercial building construction can utilize steel props for support. These props, also known as adjustable steel props or steel acrow props, are commonly used in construction projects to stabilize temporary structures. They are typically employed to provide temporary support for beams, slabs, walls, and ceilings during construction or renovation work. Steel props possess great versatility and can be adjusted to different heights, making them suitable for commercial building construction where varying height requirements may arise. They are constructed from high-quality steel, ensuring strength and durability, and are capable of withstanding heavy loads. In commercial building construction, steel props are often used alongside other support systems, such as scaffolding, to enhance stability and safety. They are easily installed and adjusted to the desired height, delivering a reliable and secure temporary support system. Furthermore, steel props are specifically designed to meet industry safety standards and regulations, guaranteeing their safe application in commercial building construction. They undergo rigorous testing and quality control measures to ensure reliability and performance. All in all, steel props are a favored choice in commercial building construction due to their strength, adjustability, and versatility. They provide temporary support and stability, facilitating efficient and safe construction processes.

- Q: Can steel props be used in basement construction?

- Indeed, basement construction can indeed make use of steel props. These adjustable and versatile temporary supports find widespread use in construction endeavors, including basement construction. They possess the purpose of offering temporary structural reinforcement throughout the construction process. By utilizing steel props, one can effectively distribute the load of walls, floors, and ceilings, thereby ensuring the stability and security of the basement structure. Moreover, steel props can be easily modified to accommodate diverse heights and angles, rendering them highly suitable for a range of basement construction necessities.

- Q: Can steel props be used for temporary support in tunnel boring operations?

- Yes, steel props can be used for temporary support in tunnel boring operations. Steel props are commonly used in construction and engineering projects to provide temporary support for structures, including tunnels. These props are designed to withstand heavy loads and can be easily adjusted or removed as needed during the tunneling process. They play a crucial role in ensuring the stability and safety of the tunnel until more permanent support systems, such as concrete linings or rock bolts, are installed.

- Q: How do you ensure proper stability of steel props on uneven surfaces?

- To ensure the proper stability of steel props on uneven surfaces, there are several important steps that need to be taken into consideration: 1. Take a thorough assessment of the uneven surface: Before setting up the steel props, it is crucial to carefully examine the uneven surface in order to gain a clear understanding of its nature and the degree of unevenness. It is important to identify any significant bumps, slopes, or irregularities that could potentially impact the stability of the props. 2. Opt for adjustable props: It is recommended to use adjustable steel props that can be extended or retracted as required. This will allow you to customize the height of the props to accommodate the uneven surface and maintain stability. 3. Ensure the props are level: Ensuring that the props are level on the uneven surface is of utmost importance. It is advisable to use a spirit level or laser level to check and adjust each prop individually. This will help evenly distribute the load and minimize the risk of the props tipping over. 4. Utilize base plates or sole boards: Placing base plates or sole boards under each prop can significantly enhance stability. These plates or boards should be sufficiently large to provide a solid foundation and prevent the props from sinking into soft or uneven ground. They also assist in distributing the load and reducing the likelihood of the props tilting. 5. Secure the props: To further increase stability, it is recommended to secure the props by using appropriate clamps or ties to connect them to the structure or adjacent props. This will prevent any lateral movement or potential collapse of the props. 6. Regularly inspect and make adjustments: It is important to periodically inspect the props throughout the duration of the work in order to ensure their stability. If any subsidence or movement is observed, it is crucial to promptly adjust the props or make necessary modifications to maintain stability. 7. Seek professional guidance: If there is any uncertainty regarding the stability of the steel props on uneven surfaces, it is advisable to consult with a structural engineer or construction professional. They can provide expert advice and recommend specific measures to ensure proper stability based on the unique characteristics of the surface and the load being supported.

- Q: Are steel props suitable for supporting suspended concrete slabs?

- Indeed, steel props prove to be a suitable option when it comes to supporting suspended concrete slabs. These adjustable and temporary supports are frequently employed in construction settings to provide reinforcement for different structural components, including suspended concrete slabs. By offering stability and strength during the construction process, steel props ensure that the weight of the slab is uniformly distributed and adequately supported. Thanks to their ability to be easily adjusted to the desired height and withstand heavy loads, steel props emerge as an optimal choice for the task of supporting suspended concrete slabs. Moreover, their durability and reliability, coupled with the ability to be reused multiple times, make them a cost-effective solution for construction projects.

- Q: Can steel props be used for temporary support in hydraulic structures?

- Yes, steel props can be used for temporary support in hydraulic structures. Steel props are strong and durable, making them suitable for providing temporary support during construction or maintenance activities in hydraulic structures such as dams, bridges, and canals. They can be easily adjusted to the required height and can withstand heavy loads. Additionally, steel props are resistant to corrosion, which is important in hydraulic structures where they may come in contact with water or moisture. However, it is important to ensure that the steel props are properly designed and installed to provide adequate support and meet the specific requirements of the hydraulic structure.

- Q: Are steel props adjustable on sloping surfaces?

- Steel props, referred to as adjustable steel props or steel jacks, can indeed be adjusted on sloping surfaces. They possess a threaded screw mechanism designed specifically for modifying their height. This characteristic enables their utilization on a multitude of surfaces, even those with inclinations. The prop's length can be effortlessly altered by rotating the threaded screw, facilitating adaptation to various gradients. Thanks to this adaptable attribute, steel props are highly versatile and well-suited for a broad spectrum of construction and support tasks, irrespective of the surface's gradient.

- Q: Can steel props be used to support concrete slabs?

- Yes, steel props can be used to support concrete slabs. Steel props, also known as adjustable steel props or scaffolding props, are commonly used in construction projects to provide temporary support to various structures, including concrete slabs. These props are adjustable in height, allowing them to be customized to the required level and provide stability and support to the concrete slab during construction or repair work. Steel props are typically made of high-quality steel, which provides strength and durability. They consist of two parts, an inner tube and an outer tube, connected by a threaded rod. The inner tube can be adjusted in height by rotating the threaded rod, while the outer tube provides additional stability and support. When using steel props to support concrete slabs, it is important to ensure that they are properly positioned and spaced to distribute the load evenly. The props should be placed at strategic locations along the slab, usually near the edges or at intervals depending on the size and weight of the slab. Additionally, the props should be securely fastened to the ground or a solid base to prevent any movement during the construction process. Using steel props to support concrete slabs offers several advantages. They are strong and can withstand heavy loads, ensuring the stability and safety of the slab. They are adjustable, making it possible to customize the height and level of support required. Additionally, steel props are easy to install and remove, providing flexibility and convenience during construction or repair work. In conclusion, steel props can indeed be used to support concrete slabs. When properly positioned and secured, these props provide stability, strength, and support, making them a reliable choice for construction projects involving concrete slabs.

- Q: What are the testing items of steel support

- Steel support quality inspection includes the following three contents: 1, processing size: steel frame processing size should meet the design requirements.

- Q: What are the disadvantages of using steel props?

- One of the main disadvantages of using steel props is their weight and bulkiness, which can make them difficult to transport and handle. Additionally, steel props require manual adjustment and can be time-consuming to set up and dismantle, leading to increased labor costs. Another drawback is that steel props can be prone to corrosion if not properly maintained, decreasing their lifespan and potentially compromising their structural integrity. Lastly, steel props may not be suitable for certain environments or applications where non-metallic or lightweight alternatives are preferred, such as in sensitive or high-load-bearing areas.

Send your message to us

Climbing Formwork- Cantilever Formwork

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords