Climbing Formwork-Cantilever Formwork

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

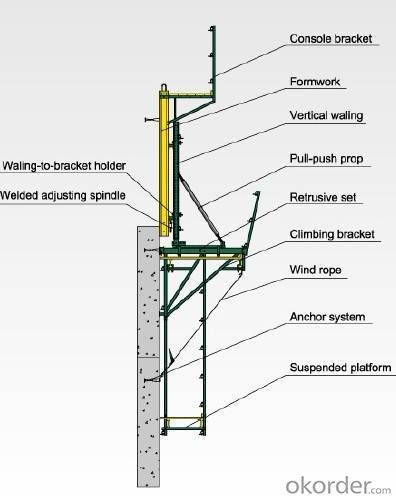

Cantilever Formwork is mainly used in the concrete pouring of pier, high buildings, and so on.

The concrete lateral pressure is entirely supported by anchor system and the wall-through tie-rods, additional reinforcement is not needed. The construction is easy, rapid and economical. A single pouring height is high and the finished concrete surface is perfect.

Cantilever formwork has several types, the structure is similar, and has its own different characteristic.The client can use them according to actual demand.

Main cantilever Formwork:PJ200 & PJ240,CB-240 etc.

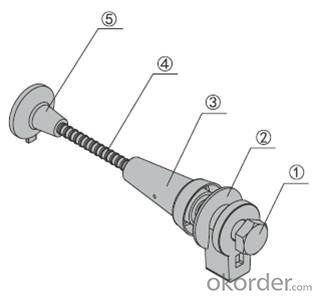

Anchor system

Anchor system is the most importantsupporting part. The system is made of five parts shown below. There into,tensile bolt, anchor shoe and bowl-climbing cone can be taken out for reusingafter the concrete pouring

① Tensile bolt M30/L= 110

② Anchor shoe

③ Bowl-climbing cone M30/D15

④ High-strength rod D15

⑤ Ancor plate D15

We dedicated to the offer the whole formwork solutions to you, which includes the design, manufacture, sale and after-sale services. Please feel free to contact us if you have any requirement.

- Q: How do you ensure proper load distribution when using steel props?

- Proper load distribution when using steel props can be ensured by following a few key steps. Firstly, it is important to accurately calculate the load-bearing capacity of the steel props and ensure that they are suitable for the particular load they will be supporting. Secondly, the props should be positioned at regular intervals along the load-bearing structure, ensuring that the load is evenly distributed across all the props. Additionally, using proper bracing and diagonal supports can help maintain the stability and distribute the load effectively. Regular inspections and maintenance of the props are also crucial to ensure their structural integrity and load distribution capabilities.

- Q: Are steel props suitable for supporting temporary bridges or walkways?

- Yes, steel props are suitable for supporting temporary bridges or walkways. Steel props are strong, durable, and have the ability to bear heavy loads. They provide excellent stability and can withstand various environmental conditions. Moreover, steel props are adjustable in height, making them versatile for different bridge or walkway designs. Their robust construction and load-bearing capacity make them a reliable choice for supporting temporary structures like bridges and walkways.

- Q: Can steel props be used for temporary support in offshore pipeline installation?

- Yes, steel props can be used for temporary support in offshore pipeline installation. Steel props are commonly used in construction and offshore projects to provide temporary support and stability during various stages of installation. They are strong, durable, and able to withstand the harsh conditions of the offshore environment, making them suitable for supporting pipelines during installation.

- Q: Steel plate spring material is not only more durable material.

- The above factors suggest that you buy Howard rubber pier cast polyurethane casting material, polyurethane elastic birthday long life in harsh environment by the strong ability to adapt.

- Q: What are the typical rental rates for steel props?

- The rental prices for steel props can differ based on several factors, such as the location, rental duration, required quantity, and prop condition. Nevertheless, as a general rule, the usual rental fees for steel props typically fall between $2 and $5 per prop per week. This charge typically covers delivery, installation, and removal services. It's important to bear in mind that these rates are approximate averages and can significantly fluctuate depending on the project's specific needs and the pricing structure of the rental company. Therefore, it is advisable to reach out to local rental companies or suppliers to obtain accurate and current rental rates for steel props in your particular area.

- Q: Can steel props be used in confined spaces?

- Yes, steel props can be used in confined spaces. Steel props are adjustable and collapsible temporary support structures commonly used in construction to provide vertical support to ceilings, walls, or beams. They are versatile and can be adapted to fit various spaces, including confined areas, as long as they meet the necessary safety requirements and are properly installed and secured.

- Q: How do you check the quality of steel props?

- To assess the quality of steel props, one can consider several key factors and methods: 1. Material inspection: Verify that the steel props are constructed from high-quality steel, such as Grade S355, which offers exceptional strength and durability. This can be done by examining the manufacturer's material certification or conducting material testing. 2. Dimensional accuracy: Utilize appropriate measuring instruments to measure the dimensions of the steel props, including length, diameter, and wall thickness. Compare the actual measurements with the manufacturer's specifications to ensure compliance with the required standards. 3. Load-bearing capacity: Determine the load-bearing capacity of the steel props by referring to the manufacturer's load charts. These charts specify the maximum loads that the props can safely support at different heights. Ensure that the props can withstand the intended loads without showing any deformation or failure. 4. Surface condition: Inspect the surface of the steel props for visible defects such as cracks, dents, or corrosion. Adequate surface treatment, such as galvanization or painting, should be present to protect the props from rust and corrosion. Surface damage can compromise the structural integrity of the props. 5. Welding quality: If the steel props are assembled through welding, inspect the quality of the welds. Check for proper penetration, absence of porosity or cracks, and uniformity of the weld bead. The welds should adhere to relevant welding standards, such as AWS D1.1 or EN ISO 3834. 6. Certification and compliance: Ensure that the steel props comply with relevant industry standards and regulations, such as EN 1065 or ANSI/ASSE A10.9. Look for certification marks, such as CE marking, which indicate that the props have undergone testing and meet the necessary safety and quality standards. 7. Manufacturer reputation: Take into account the reputation and track record of the manufacturer. Select reputable suppliers with a history of producing high-quality steel props and providing dependable customer support. It is advisable to involve a qualified engineer or a third-party inspection agency to conduct these assessments, ensuring accurate and unbiased evaluation of the steel props' quality.

- Q: Can steel props be used in road construction?

- Road construction often involves the use of steel props. These props, also known as adjustable steel props or acrow props, are commonly employed in the construction industry to provide temporary support and hold structures or formwork during projects. When it comes to road construction, steel props are frequently utilized to stabilize and support temporary structures like scaffolding, formwork, or concrete barriers. They are also relied upon to offer additional support to excavated areas or trenches during the creation of road foundations or underground utilities. The preference for steel props in road construction arises from their strength, durability, and adjustability. They can easily be adjusted to the required height, providing flexibility in various construction scenarios. Furthermore, steel props are lightweight and portable, which contributes to their efficiency and cost-effectiveness in road construction endeavors. In addition, steel props boast a high load-bearing capacity, ensuring the stability and safety of construction sites. They are capable of withstanding heavy loads and offering reliable support to the structures and formwork employed in road construction. Overall, steel props are a valuable asset in road construction as they offer temporary support and stability to a range of structures and formwork used throughout the construction process.

- Q: How do steel props prevent structural collapse during construction?

- Steel props, also known as adjustable steel props or acrow props, play a crucial role in preventing structural collapse during construction. These temporary supports are widely used in the construction industry to provide stability and reinforce structures during various stages of the building process. One of the primary functions of steel props is to transfer the weight load of the structure and distribute it evenly to the ground. Construction sites often involve the removal or alteration of load-bearing walls or columns, which can weaken the overall stability of the structure. Steel props are strategically placed under the areas where the load-bearing elements have been removed, providing temporary support to prevent collapse. Moreover, steel props are adjustable in height, allowing construction workers to customize the support according to the specific requirements of the project. This adjustability is crucial as it ensures that the structure remains stable as different stages of construction progress. It also enables workers to compensate for uneven or sloping surfaces, providing a level base for the load-bearing elements. Another advantage of steel props is their robustness and load-bearing capacity. They are typically made of high-quality steel, which makes them strong and capable of withstanding heavy loads. These props can support various structures, including beams, slabs, walls, and ceilings, ensuring their stability throughout the construction process. Furthermore, steel props are designed to be easy to install and dismantle, making them convenient and time-efficient for construction projects. Their versatility and flexibility allow construction workers to quickly adjust and reposition the props as needed, accommodating changing load requirements and construction sequences. In conclusion, steel props are essential in preventing structural collapse during construction by providing temporary support, distributing weight loads evenly, and compensating for the removal or alteration of load-bearing elements. Their adjustability, robustness, and ease of installation make them an indispensable tool in ensuring the stability and safety of structures throughout the construction process.

- Q: Can steel props be used in hospital renovation projects?

- Hospital renovation projects can indeed utilize steel props. These props are frequently employed in construction and renovation endeavors to afford temporary support to structures. Their adjustability and ease of installation render them well-suited for a range of applications, including hospital renovations. By using steel props, ceilings, walls, and floors can be adequately supported during renovation work, guaranteeing the security and stability of the building. Moreover, their height can be adjusted to meet specific requirements, thereby offering flexibility in accommodating diverse project needs. Consequently, steel props stand as a dependable and effective solution for hospital renovation projects.

Send your message to us

Climbing Formwork-Cantilever Formwork

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords