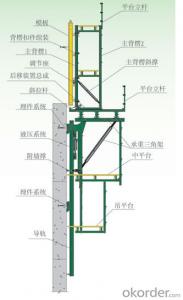

Auto-Climbing Formwork, for high buildings and bridge

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1

- Supply Capability:

- 20 /month

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

You Might Also Like

The power of the Auto climbing Formwork is the hydraulic system, which includes theoil cylinder and two commutators etc. The commutators can control the climbing of climbing rail and the bracket. The steel rail and the bracket can inner-climbing, so the whole system will climb upsteadily.

Cranes are not needed during the constructing. It is easy to operate, highly efficient and safe. It is the best choice for the construction of highbuildings and bridges.

Characteristics

Safety:

1.The system can climb integrallyor separately.

2.The climbing process is steady,synchronous and safe.

3.Excellent operating platform handrail and aisle can be lifted together with the formwork.

4.The climbing speed is quick, which can shorten the construction period and reduce the construction cost.

- Q: Can steel props be used for supporting temporary fencing in high-security areas?

- Indeed, the utilization of steel props proves to be effective in bolstering temporary fencing in high-security zones. With their strength and durability, steel props are an optimal choice for providing stability and support to temporary fencing systems. They are capable of withstanding strong winds and other external forces, thereby guaranteeing that the fencing remains intact and delivers the necessary security. In areas where the likelihood of intrusion or unauthorized access is elevated, it becomes imperative to possess a fencing system that is steadfast and dependable. Steel props offer the advantage of easy height adjustment, affording flexibility in the installation of temporary fencing. Furthermore, their robust construction deters tampering or damage, thereby fortifying security measures. Moreover, steel props exhibit resistance to corrosion, a particularly vital characteristic in regions with inclement weather or exposure to moisture. This resistance ensures the long-lasting strength and integrity of the props, diminishing the frequency of replacements or repairs. In summary, steel props are a suitable option for supporting temporary fencing in high-security areas due to their robustness, durability, adjustability, and corrosion resistance. They establish a solid foundation for the fencing system, guaranteeing the highest level of security and protection.

- Q: Can steel props be used for temporary support in railway construction?

- Yes, steel props can be used for temporary support in railway construction. Steel props are commonly used in construction projects to provide temporary support to structures until they are able to support themselves. In railway construction, steel props can be used during the installation of new tracks, bridges, or tunnels. They can be used to support the weight of heavy machinery or equipment during the construction process. Steel props are strong, durable, and easily adjustable, making them an ideal choice for temporary support in railway construction.

- Q: What are the potential aesthetic considerations when using steel props?

- When incorporating steel props, one must keep in mind various aesthetic factors. Firstly, the overall aesthetic of a space can be influenced by the appearance of the steel props themselves. Contemporary or minimalist designs may find the sleek and industrial look of steel props appealing. However, in traditional or rustic settings, steel props may clash with the desired aesthetic. In such cases, alternative materials or finishes may need to be considered to blend the steel props with the overall design scheme. The visibility of the steel props within the space is another aesthetic consideration. Depending on the design intent, some may prefer the steel props to be prominently displayed as a design feature, while others may prefer them to be discreetly hidden. Careful consideration should be given to the size, shape, and placement of the steel props to ensure they align with the desired aesthetic and do not detract from the overall visual appeal of the space. The surface finish and treatment of the steel props can also impact their aesthetic appeal. Steel props can be left in their raw state, showcasing a natural steel finish that adds an industrial and rugged charm. Alternatively, they can be painted or powder-coated to match the surrounding elements or achieve a specific color scheme. The choice of finish should harmonize with the overall aesthetic goals of the space and enhance its visual appeal. Lastly, the integration of steel props with other materials and elements in the design is an important aesthetic consideration. Steel props can be used alongside materials such as wood, glass, or concrete, and the combination of these materials must be carefully considered to achieve a cohesive aesthetic. The juxtaposition of steel with other materials can create interesting visual contrasts, but it is crucial to strike a balance and ensure that the combination enhances the overall aesthetic rather than creating a discordant visual effect. In conclusion, when using steel props, it is essential to consider their appearance, visibility, surface finish, and integration with other materials. By carefully evaluating these factors, designers can create a harmonious and visually appealing space that aligns with their aesthetic goals.

- Q: What are the common methods of testing steel props for structural integrity?

- The common methods of testing steel props for structural integrity include visual inspection, non-destructive testing (NDT) techniques, and load testing. 1. Visual Inspection: This is the initial and simplest method to assess the condition of steel props. It involves a thorough visual examination of the props to detect any visible signs of damage, such as cracks, deformations, corrosion, or misalignment. This method helps identify any obvious defects that may compromise the structural integrity of the props. 2. Non-Destructive Testing (NDT) Techniques: NDT techniques are commonly used to evaluate the internal condition of steel props without causing damage to the material. Some common NDT techniques used for steel props include: - Ultrasonic Testing: This method uses high-frequency sound waves to detect internal flaws or defects in the props. Ultrasonic waves are sent into the material, and the reflections are analyzed to identify any irregularities. - Magnetic Particle Testing: This technique is suitable for detecting surface or near-surface defects in steel props. It involves applying a magnetic field to the props and then applying magnetic particles to the surface. If there are any defects, the particles will be attracted and form visible indications. - Dye Penetrant Testing: This method is used to identify surface cracks or defects in steel props. A liquid dye penetrant is applied to the surface, which seeps into any cracks or defects. Excess dye is then removed, and a developer is applied to make the indications visible. 3. Load Testing: Load testing involves subjecting the steel props to a specified load to assess their ability to withstand the expected loads in real-world applications. This method helps determine the load-carrying capacity and overall strength of the props. Load testing can be done using hydraulic jacks, loading frames, or specialized load testing equipment. It is important to note that the specific testing methods used may vary depending on the applicable standards, regulations, and requirements of the project or industry. Professional engineers or specialized testing laboratories should be consulted to ensure proper testing techniques are employed to evaluate the structural integrity of steel props.

- Q: How much is the glass floor cost. That's the kind of steel frame

- The use of the environment, load-bearing, non slip performance, steel selection, etc.,

- Q: Can steel props be used in mining tunnel construction?

- Yes, steel props can be used in mining tunnel construction. Steel props offer strong support and stability to the tunnel walls, ensuring the safety of the construction process. Additionally, steel props are durable and can withstand the harsh conditions commonly found in mining environments.

- Q: Can steel props be used in the construction of underground parking garages?

- Underground parking garages can incorporate steel props, also called steel shoring or steel shores, for structural support during construction. These props provide temporary support to the structures and prevent collapse or failure. They are designed to bear heavy loads and can be easily adjusted to offer necessary support in various areas of the garage. Steel props are particularly advantageous for underground construction because they can be easily installed and adjusted to fit the different heights and dimensions of the garage. Once permanent support systems like columns and beams are in place, the props can be readily removed. Moreover, steel props have the benefit of reusability, which reduces construction costs and waste. They are highly durable and resistant to corrosion, making them suitable for long-term use in underground environments. However, it is crucial to comply with local building codes and regulations when utilizing steel props in underground parking garages. Consulting with structural engineers and construction professionals is essential to ensure proper design, installation, and implementation of safety measures.

- Q: How do steel props contribute to the overall quality of construction projects?

- Steel props contribute to the overall quality of construction projects by providing reliable and sturdy support for temporary structures, such as formwork and scaffolding. They help distribute the weight and load evenly, ensuring the stability and safety of the construction site. Additionally, steel props allow for easy adjustment and quick installation, improving efficiency and productivity during the construction process. Their durability and strength also enhance the longevity and structural integrity of the project, ultimately leading to a higher quality end result.

- Q: Can steel props be used in both residential and commercial construction projects?

- Yes, steel props can be used in both residential and commercial construction projects. Steel props, also known as adjustable steel shoring posts or acrow props, are commonly used to support temporary structures or provide additional support during construction or renovation work. These props can be adjusted in height and are made of durable and strong steel, allowing them to bear heavy loads. Due to their versatility and strength, steel props are suitable for a wide range of applications, including both residential and commercial construction projects. They can be used to support formwork, scaffolding, beams, walls, and other structural elements in buildings of various sizes. Whether it is for constructing a residential home, office building, retail complex, or any other commercial structure, steel props offer a reliable and efficient solution for temporary support needs.

- Q: Do steel props have any adjustable base plates for uneven surfaces?

- Yes, steel props typically have adjustable base plates that can accommodate uneven surfaces. These base plates are designed to be adjustable in order to provide stability and support on various types of terrain. They can be easily manipulated to ensure that the steel prop is securely positioned, even on uneven ground. This adjustability feature is particularly important in construction and building projects where the ground may not be perfectly level.

Send your message to us

Auto-Climbing Formwork, for high buildings and bridge

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1

- Supply Capability:

- 20 /month

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

Similar products

Hot products

Hot Searches

Related keywords