4x8 Sheets of Aluminum Profiles ZL-18745 for LED Display Frame

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 20 m.t.

- Supply Capability:

- 2000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1.Structure of Auminum Profiles ZL -18745 for Led Display Frame Description:

Anodizing (also spelled anodising, particularly in the UK and Australia) is an electrolytic passivation process used to increase the thickness of the natural oxide layer on the surface of metal parts. Anodized aluminium surfaces, for example, are harder than aluminium but have low to moderate wear resistance that can be improved with increasing thickness or by applying suitable sealing substances.

2.Main Features of the Auminum Profiles ZL -18745 for Led Display Frame:

High corrosion-resistance;

weather-resistance;

heat-resistance;

alkali-resistance and impact-resistance properties.

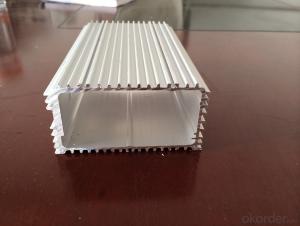

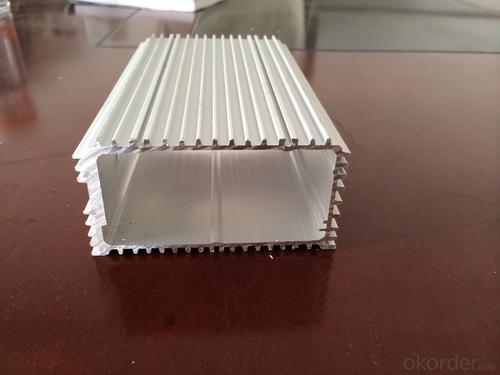

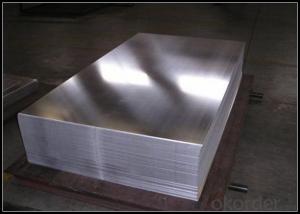

3.Auminum Profiles ZL -18745 for Led Display Frame Images:

4.Auminum Profiles ZL -18745 for Led Display FrameSpecification:

1. Material: 6063,6061,6060,6005,6005A,etc.

2. Temper: T5 or T6

3. Finish: Mill finish, anodizing, powder coating, electrophoresis, wooden transfer or pvdf/carbon-flouride coated, polishing, brushing, sand blasting

4. Various colors: Silver, bronze, black, gold, blue, grey, champagne, bright, etc.

5. Machining: Cutting, punching, drilling, tapping, milling, bending, welding, CNC etc.

5.FAQ:

① How about your company?

A world class manufacturer & supplier of castings forging in carbon steel and alloy steel,is one of the large-scale professional investment casting production bases in China, consisting of both casting foundry forging and machining factory. Annually more than 8000 tons Precision casting and forging parts are exported to markets in Europe, America and Japan. OEM casting and forging service available according to customer’s requirements.

②How to guarantee the quality of the products?

We have established the international advanced quality management system,every link from raw material to final product we have strict quality test;We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

- Q: This question asks if aluminum sheets are appropriate for use in regions with cold temperatures.

- <p>Aluminum sheets are generally suitable for use in cold climates. They have excellent resistance to corrosion and maintain their structural integrity in low temperatures. However, aluminum is a good conductor of heat, so it can be prone to heat loss if not properly insulated. For outdoor applications in cold climates, it's important to ensure that aluminum structures are well-insulated to prevent heat transfer. Additionally, aluminum's malleability can make it susceptible to denting or damage from ice and snow, so protective measures may be necessary.</p>

- Q: Are 101 aluminum sheets suitable for decorative purposes?

- Yes, 101 aluminum sheets are suitable for decorative purposes. They offer a sleek and modern look, are lightweight, and can be easily customized or shaped to create various decorative elements.

- Q: Is aluminum sheet resistant to UV rays?

- Yes, aluminum sheet is resistant to UV rays. Aluminum naturally forms a protective oxide layer that acts as a barrier against UV radiation. This oxide layer helps to prevent the aluminum sheet from being damaged or degraded by exposure to the sun's UV rays. This makes aluminum sheet a suitable material for outdoor applications, where it can withstand prolonged exposure to sunlight without fading or deteriorating. Additionally, the reflective properties of aluminum further contribute to its UV resistance, as it can reflect a significant amount of the sun's rays, reducing heat absorption and potential damage.

- Q: Which explains aluminum's resistance to corrosion? Any aluminum oxide that forms readily falls off the metal and exposes the corrosion-resistant metal. The aluminum oxide that forms adheres to the metal surface. The reduction half-reaction Al3+(aq) + 3e- ---gt; Al(s) occurs readily. The standard reduction potential for the Al3+/Al half-reaction is above the standard reduction potential for the O2/H2O half-reaction.

- the fourth statement.

- Q: Dear all, i'm having crack problem with bending aluminium sheet metal, anyone know than which type(Model) of aluminium sheet metal is suitable for bending, Thanks.

- THERE WERE MANY TYPES OF ALUMINUM ACCORDING TO ITS RIGIDITY. Please refer to RS Industrial catalogue for your data references.

- Q: Can 101 aluminum sheets be customized in terms of size and thickness?

- Yes, 101 aluminum sheets can be customized in terms of size and thickness according to specific requirements and needs.

- Q: doesn't particularly need to be welding but i need to make an air tight permanent seal around 2 very thin sheets of aluminium (like .02 inches thick) i was thinking .02 inch 5052 aluminum because its the thinnest i can find but am obviously up for suggestions.

- First you need a Tungsten inert gas welder (T.I.G. for short). The second step is to make sure the aluminum is clean. If you just bought it , and it looks clean ; it isn't trust me. Steel and aluminum are totally different in a lot of ways and that is one of them. I'm going to skip the safety instructions and shopping list , under the presumption that you already know the basics. Spray the area to be welded with acetone. rinse with clean water to remove lingering residue. then use a wire brush that has never been used on anything but Aluminum to clean the area. I'd go with a 4043 welding rod , it's a popular choice. Make sure to use clamps so that the 2 pieces of metal are squeezed tightly together with no gaps. (very important) I like to preheat my metal even if it's thin sheets , seems to come out better although it isn't usually called for in specs. side note ; If you have to step away from your work for more than 8 hours , you're going to need to re-prep it since it will have formed a layer of Aluminum oxide by that time.

- Q: Are aluminum sheets suitable for cladding?

- Yes, aluminum sheets are suitable for cladding due to their durability, lightweight nature, and corrosion resistance. Additionally, aluminum offers versatility in terms of design options and ease of installation, making it a popular choice for cladding applications in various industries.

- Q: Are 101 aluminum sheets suitable for high-temperature applications?

- No, 101 aluminum sheets are not suitable for high-temperature applications as they have a low melting point and may deform or melt under high temperatures.

- Q: Are the aluminum sheets suitable for manufacturing heat exchangers?

- Yes, aluminum sheets are suitable for manufacturing heat exchangers due to their excellent thermal conductivity, lightweight nature, and corrosion resistance.

Send your message to us

4x8 Sheets of Aluminum Profiles ZL-18745 for LED Display Frame

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 20 m.t.

- Supply Capability:

- 2000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords