ASTM INOX 304 HL Stainless Steel Sheet / Coil

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m.t.

- Supply Capability:

- 20000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

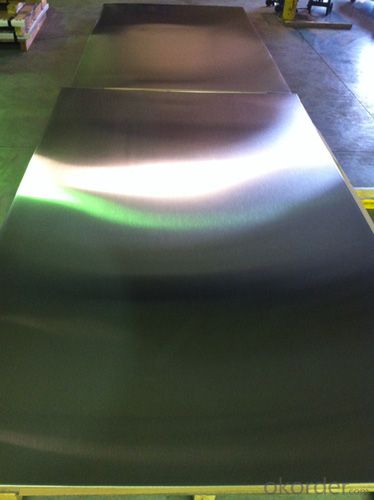

ASTM INOX 304 HL Stainless Steel Sheet / Coil

Packaging Details:Wooden pallets,water proof paper-20'GP or 40'GP for stainless steel sheet.

Delivery Detail:within 5-7 days after receiving the deposit

1. Specifications about stainless steel sheet

Commodity | Professional 430 201 202 304 304l 316 316l 321 310s 309s 904l stainless steel sheet |

Grade | 201,202,304,304L,316,316L,310S,309S,321,301,310,410,420,430,904L |

Brand | TISCO ,BAOSTEEL,POSCO,JISCO,LISCO |

Certification | SGS,BV,IQI,TUV,ISO,etc |

Thickness | 0.2mm-150mm |

Width | 1000,1219,1250,1500mm, or as your requirements |

Length | 2000,2438,2500,3000,6000mm, or as your requirements |

Surface | No.1, 2B, BA, 8K Mirror, Hairline,satin, Embossed,brush,No.4,HL,matt,pvc film,laser film. |

Standard | ASTM,AISI,SUS,JIS,EN,DIN,GB, ASME,etc |

Delivery time | 5-7 days after confirming the order |

MOQ | 1 Ton |

Advantages | Showing the splendor of your quality, wearresistant as well , strong corrosion resistance and decorative effect, durable and beautiful in good taste. |

2.Production Flow about stainless steel sheet

Raw materials are sending to hot rolling units for rolling into different sizes

Hot rolled material is annealing in cold; rolled annealing furnace and pickling in acid.

All mill rolls are grinded on precision grinding machine with proper chamfering after first shiftoperation.

All sheets are pickled in different tanks and dried on brush roll machine before dispatched.

These sheets are again annealing and are sent to straighten machine for straightening.

Inspections are done at various stages. Keep proper control overall internal process via rolling,annealin and pickling by our experienced staff.

3.Surface--stainless steel sheet

| Surface Finish | Definition | Application |

| 2B | Those finished, after cold rolling, by heat treatment, pickling or other equivalent treatment and lastly by cold rolling to given appropriate luster. | Medical equipment, Food industry, Construction material, Kitchen utensils. |

BA/8K mirror | Those processed with bright heat treatment after cold rolling. | Kitchen utensils, Electric equipment, Building construction. |

| NO.3 | Those finished by polishing with No.100 to No.120 abrasives specified in JIS R6001. | Kitchen utensils, Building construction. |

| NO.4 | Those finished by polishing with No.150 to No.180 abrasives specified in JIS R6001. | Kitchen utensils, Building construction, Medical equipment. |

| Hairline | Those finished polishing so as to give continuous polishing streaks by using abrasive of suitable grain size. | Building Construction. |

| NO.1 | The surface finished by heat treatment and pickling or processes corresponding there to after hot rolling. | Chemical tank, pipe. |

- Q: How do you prevent fingerprints and smudges on stainless steel sheets?

- To prevent fingerprints and smudges on stainless steel sheets, there are a few effective methods you can follow: 1. Clean with microfiber cloth: Use a soft microfiber cloth to wipe the stainless steel surface. Microfiber is gentle and won't leave any scratches or streaks. Avoid using rough materials like paper towels or abrasive sponges. 2. Use a stainless steel cleaner: Invest in a high-quality stainless steel cleaner specifically designed for removing fingerprints and smudges. Follow the instructions on the cleaner and apply it evenly on the surface using a cloth or a sponge. Wipe off any excess cleaner with a clean cloth. 3. Apply baby oil or mineral oil: Apply a small amount of baby oil or mineral oil on a cloth and rub it gently over the stainless steel surface. This will create a thin protective layer that helps prevent fingerprints and smudges from sticking to the metal. 4. Avoid touching the surface with bare hands: One of the main causes of fingerprints and smudges is direct contact with hands. Try to handle stainless steel sheets with clean, dry hands or wear gloves if necessary. This will help minimize the transfer of oils and residue onto the surface. 5. Regular cleaning routine: Establish a regular cleaning routine for your stainless steel sheets. Wipe them down with a microfiber cloth or stainless steel cleaner at least once a week, or more frequently in high-traffic areas. This will prevent the buildup of oils and grime, reducing the chances of fingerprints and smudges. By following these methods, you can effectively prevent fingerprints and smudges on stainless steel sheets, keeping them looking clean and shiny for an extended period of time.

- Q: Are stainless steel sheets suitable for food processing or medical applications?

- Yes, stainless steel sheets are highly suitable for both food processing and medical applications. Stainless steel is corrosion-resistant, durable, and easy to clean, making it ideal for environments where hygiene and cleanliness are crucial. It is also non-reactive with food or medical substances, ensuring that it does not contaminate or alter the properties of the materials it comes into contact with. Additionally, stainless steel's strength and resistance to extreme temperatures make it suitable for various processing and sterilization methods required in these industries.

- Q: Are stainless steel sheets suitable for cleanroom applications?

- Yes, stainless steel sheets are highly suitable for cleanroom applications. They possess excellent corrosion resistance, durability, and a smooth surface that is easy to clean and maintain. Additionally, stainless steel sheets can withstand high temperatures and are resistant to chemicals, making them an ideal choice for cleanroom environments requiring high levels of cleanliness and hygiene.

- Q: Can stainless steel sheets be used in high-temperature applications?

- Indeed, high-temperature applications can utilize stainless steel sheets. Renowned for its superb heat resistance characteristics, stainless steel proves itself adaptable in environments boasting elevated temperatures. Notably, it boasts a formidable melting point, ensuring its durability and structural integrity endure even under extreme conditions. Furthermore, stainless steel showcases commendable oxidation resistance, thwarting scale formation and preserving its surface's sleekness. Consequently, stainless steel sheets rank favorably when considering their widespread employment in diverse high-temperature settings, encompassing heat exchangers, furnaces, boilers, and exhaust systems.

- Q: Can stainless steel sheets be used for filtration applications?

- Yes, stainless steel sheets can be used for filtration applications. Stainless steel is known for its corrosion resistance and durability, making it an excellent choice for filtration systems. The sheets can be formed into various filter elements, such as screens, discs, or cartridges, to suit different filtration needs. Stainless steel sheets offer high mechanical strength, allowing them to withstand high pressures and temperatures without deformation. Additionally, stainless steel can be easily cleaned and sanitized, making it suitable for applications where hygiene is crucial, such as in the food and beverage industry. Overall, stainless steel sheets are widely used in filtration applications due to their excellent performance and reliability.

- Q: What is the width range available for stainless steel sheets?

- The width range available for stainless steel sheets can vary depending on the supplier, but it typically ranges from 36 inches to 72 inches.

- Q: How do I prevent corrosion under insulation on stainless steel sheets?

- To prevent corrosion under insulation on stainless steel sheets, it is essential to ensure proper installation and maintenance. Firstly, use high-quality insulation materials that are resistant to moisture and have a vapor barrier to prevent any water penetration. Secondly, ensure that the stainless steel sheets are installed correctly, with no gaps or exposed areas that could allow moisture accumulation. Regular inspections and maintenance, including repairing damaged insulation or sealing any gaps, are crucial to prevent moisture ingress. Additionally, applying a suitable corrosion inhibitor on the stainless steel surface can provide an extra layer of protection.

- Q: Are stainless steel sheets suitable for marine environments?

- Yes, stainless steel sheets are highly suitable for marine environments. Stainless steel is known for its excellent corrosion resistance properties, making it ideal for withstanding the harsh conditions of saltwater and exposure to moisture in marine environments. It is highly resistant to rust, corrosion, and staining, which allows it to maintain its structural integrity and appearance even in challenging marine conditions. Stainless steel sheets are commonly used in marine applications such as shipbuilding, offshore platforms, and marine equipment due to their durability and longevity in these environments.

- Q: Can stainless steel sheets be used for electromagnetic compatibility?

- Yes, stainless steel sheets can be used for electromagnetic compatibility (EMC). Stainless steel has good electrical conductivity and is often used as a shielding material to prevent the interference of electromagnetic fields. It can effectively block electromagnetic radiation and provide a barrier against external electromagnetic waves. Additionally, stainless steel's durability and corrosion resistance make it suitable for long-term EMC applications.

- Q: Can stainless steel sheets be used for signage?

- Stainless steel sheets are indeed capable of serving as signage. This material possesses durability and longevity, being highly resistant to corrosion, thereby rendering it suitable for both indoor and outdoor applications. Its sleek and contemporary appearance contributes to its popularity across various signage types, encompassing company logos, directional signs, nameplates, and even expansive outdoor billboards. The flexibility of stainless steel sheets allows for easy customization through cutting, engraving, or laser-etching, thereby offering a vast array of creative possibilities. Furthermore, the choice of stainless steel signage often stems from its ability to withstand adverse weather conditions, UV rays, and acts of vandalism, thereby preserving the integrity and legibility of the signage for numerous years.

Send your message to us

ASTM INOX 304 HL Stainless Steel Sheet / Coil

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m.t.

- Supply Capability:

- 20000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords