304 316L 430 201 Inox Stainless Steel Coil/Sheet/Plate !!!

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2 m.t.

- Supply Capability:

- 5000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Factory supply 304 316L 430 201 inox stainless steel coil/sheet/plate !!!

Specifications:

All Materials: 304, 304L, 316,316L, 321, 310S, 309S,317,201, 202,410,420,430,904L

Thickness: 0.2mm-60mm

Width: 1000-2000mm or as your request

Surface: No.1, 2B, Hairline, No.4, BA, 8K mirror finish,No.2,pvc coating

Applications:

Stainless Steel is widely used in Kitchenware, cutlery, household hardware, surgical instruments, major appliances, industrial equipment and as an automotive and aerospace structural alloy and construction material in large buildings. Storage tanks and tanker used to transport orange juice and other food are often made of stainless steel, because of its corrosion resistance and antibacterial properties. This also influences its use in commercial kitchens and food processing plants, as it can be steam-cleaned and sterilized and does not need paint or other surface finishes.

More Details:

Product name | Stainless Steel Plate |

Standard | ASTM, AISI, JIS, GB, DIN |

Length | 1m-12m or as your request |

Place of Origin | Shanxi, China (Mainland) |

Brand Name | TISCO , LISCO, Bao Steel, |

Type | Plate |

Certification | ISO Certificate, Mill Test Certificate,SGS,BV |

Application | Kitchenware, Tanks, Food Processing, cutlery, construction, household hardware, surgical instruments, major appliances, industrial equipment and as an automotive and aerospace structural alloy |

Technical treatment | Cold Rolled, Hot Rolled |

MOQ | 1 Metric Ton |

Terms of delivery | FOB, CNF, CIF |

Terms of Payment | L/C, T/T |

Port of Loading | Shanghai / Guangzhou/Shenzhen/Tianjin of China |

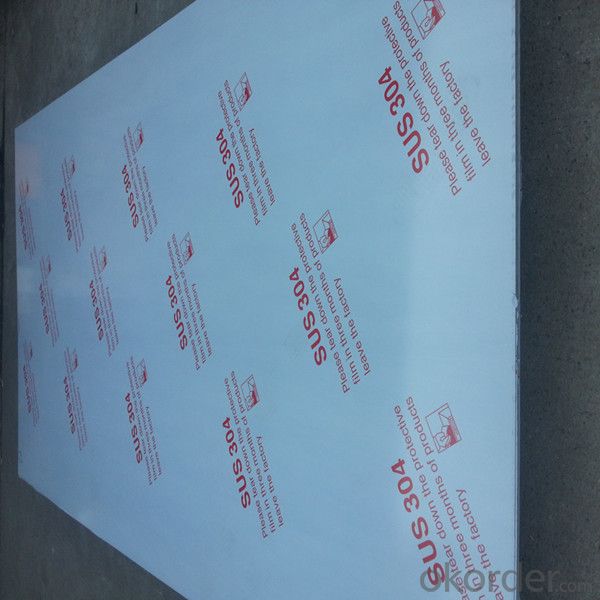

Packing | In bundles, packed with Water proof paper and wooden pallet. To be packed strongly avoid damage during transportation, and can be also according to the regulations and customer’s requests. Furthermore, products packages also are tagged clear on the outside for easy identification of the product and quality information. |

Time of delivery | Normally within 10-15 working days after receiving the deposit |

Stock | Ready In stocks |

Packing--stainless steel plate

Bundles, seaworthy wooden pallets or wooden cases.With or without edge protector, steel hoop and seals, in 20' or 40' container

or as per customers' requirements

Stainless steel maintenance:

(1) Regular cleaning and maintenance

(2) Pay attention to prevent the occurrence of the phenomenon of surface scratches

(3) Use soap, weak detergent or warm water to remove surface dust, dirt

(4) In addition to the surface of the binder with alcohol or an organic solvent (ether, benzene)

(5) Use neutral detergent or ammonia solution in addition to surface oil

(6) With 10% nitric acid or abrasive detergent in addition to the surface of the embroider caused by the dirt.

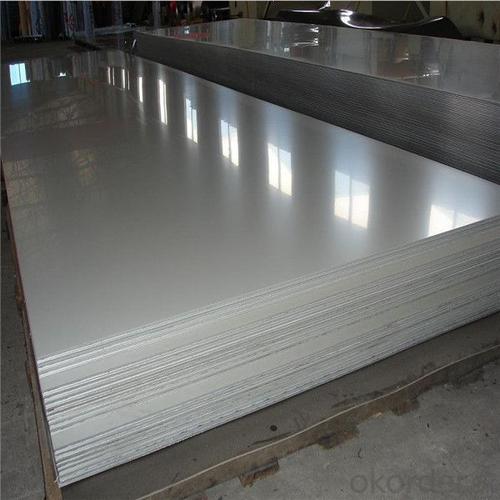

Products display

- Q: What is the composition of stainless steel sheets?

- Comprised mainly of iron, chromium, and other elements like nickel, manganese, and carbon, stainless steel sheets possess exceptional strength and durability. Iron, being the primary constituent, imparts resilience and sturdiness to these sheets, whereas chromium is incorporated to enhance their resistance against corrosion. By adding nickel, the sheets' ability to withstand high temperatures is bolstered, along with an improvement in their overall mechanical properties. Manganese is introduced to augment their malleability, while carbon contributes to elevating their hardness. The harmonious collaboration of these elements results in a versatile and remarkably dependable material that finds extensive application across diverse industries, including construction, automotive, and manufacturing.

- Q: What is the maximum thickness of a stainless steel sheet?

- The maximum thickness of a stainless steel sheet can vary depending on the specific type and grade of stainless steel being used. However, stainless steel sheets are commonly available in thicknesses ranging from 0.4mm to 6mm or even thicker for certain industrial applications.

- Q: How do stainless steel sheets resist corrosion?

- Stainless steel sheets resist corrosion due to the presence of chromium, which forms a protective layer on the surface of the material. This layer, known as chromium oxide, acts as a barrier against moisture, oxygen, and other corrosive substances, preventing them from reaching the underlying steel and causing corrosion.

- Q: What are the benefits of using mirror-finish stainless steel sheets?

- Mirror-finish stainless steel sheets offer several benefits. Firstly, they provide a sleek and modern aesthetic appeal, making them a popular choice for interior and architectural design. Additionally, the reflective surface of these sheets creates the illusion of a larger space, making them ideal for small areas. Mirror-finish stainless steel also has superior corrosion resistance, making it a durable option for outdoor applications. The smooth surface is easy to clean and maintain, reducing the need for frequent upkeep. Finally, mirror-finish stainless steel sheets are often used in food processing and medical industries due to their hygienic properties and ability to resist bacterial growth.

- Q: How do you form stainless steel sheets into different shapes?

- Stainless steel sheets can be formed into different shapes through various processes such as bending, cutting, and welding. Bending can be achieved by using specialized tools like press brakes or rollers to apply force and reshape the sheet. Cutting techniques like shearing or laser cutting can be used to create desired shapes or sizes. Additionally, welding is employed to join different stainless steel sheets together, enabling the formation of complex structures and shapes.

- Q: How do you cut stainless steel sheets?

- Different methods can be employed to cut stainless steel sheets, depending on the sheet's thickness and the desired level of precision. Here are several commonly used techniques: 1. Manual cutting: Thinner stainless steel sheets (up to approximately 16 gauge) can be cut using handheld shears or tin snips. These tools allow for straight or curved cuts by applying pressure and slicing through the sheet. However, this approach may not be suitable for thicker sheets due to its labor-intensive nature and the potential for producing rough edges. 2. Power shears: When dealing with thicker stainless steel sheets, power shears or electric nibblers prove more efficient. These tools employ a sharp cutting blade or punch to make straight or curved cuts. They offer greater precision and require less effort compared to manual cutting methods. 3. Circular saw: Stainless steel sheets of increased thickness can also be cut using a circular saw outfitted with a carbide-tipped blade specifically designed for metal cutting. This method allows for straight cuts but may generate more noise, sparks, and heat. Consequently, appropriate safety measures, such as wearing protective goggles and gloves, should be taken. 4. Plasma cutting: Plasma cutting is commonly utilized for industrial or heavy-duty applications. This technique involves employing a high-temperature plasma jet to melt through the stainless steel sheet, generating a precise and clean cut. However, plasma cutting machines are expensive and necessitate specialized training in operation. Irrespective of the chosen method, it is crucial to prioritize safety when cutting stainless steel sheets. Always wear protective gear, such as safety glasses, gloves, and a dust mask, to safeguard against metal shards, sparks, and dust. Moreover, ensure that the sheet is securely clamped or supported to prevent any movement during the cutting process.

- Q: What are the different types of stainless steel sheet surface textures available?

- Stainless steel sheets come in a variety of surface textures, each with its own unique visual and functional properties. Here are some of the most commonly used surface finishes: 1. No.1 Finish: This is the most widely used surface finish for stainless steel sheets. It is achieved by hot rolling the steel and then annealing it, resulting in a smooth and reflective surface. 2. No.2B Finish: Compared to No.1 finish, this finish has a slightly rougher texture. It is achieved by cold rolling the steel and then annealing it, giving it a dull and matte appearance. 3. No.4 Finish: Also known as satin or brushed finish, this surface texture has a fine grain appearance with short, parallel lines. It is achieved by polishing the surface with abrasive belts or brushes. 4. Hairline Finish: Similar to No.4 finish, this surface texture has a finer grain appearance. It is achieved by polishing the surface with abrasive belts or brushes in a unidirectional pattern. 5. No.8 Mirror Finish: This is the most reflective surface texture available for stainless steel sheets. It has a highly polished and mirror-like appearance, achieved by further polishing the surface after No.4 finish. 6. Bead Blasted Finish: This surface texture is achieved by blasting the stainless steel sheet with fine glass beads or ceramic particles. It results in a textured, non-reflective surface with a uniform matte appearance. 7. Embossed Finish: This surface texture involves imprinting a pattern or design onto the stainless steel sheet. It can be achieved through mechanical embossing or by using a special roller during the manufacturing process. 8. Colored Finishes: In addition to the above surface textures, stainless steel sheets can also be coated with various colors to enhance their visual appeal. These colored finishes are achieved through processes like PVD (Physical Vapor Deposition) or powder coating, resulting in a durable and vibrant surface. These are just a few examples of the many surface textures available for stainless steel sheets. The choice of surface texture depends on the desired aesthetic, functional requirements, and specific application of the stainless steel sheet.

- Q: Can stainless steel sheets be formed into complex shapes?

- Complex shapes can indeed be formed from stainless steel sheets. Stainless steel is renowned for its exceptional formability and versatility, establishing it as a highly utilized material across numerous industries. It can be readily manipulated through various fabrication techniques like bending, rolling, stamping, and deep drawing, facilitating the creation of intricate shapes with utmost precision and accuracy. Furthermore, stainless steel possesses remarkable ductility, enabling it to endure substantial deformation while retaining its mechanical properties and structural integrity. Consequently, it is frequently favored for applications necessitating intricate and tailored designs, including architectural structures, automotive components, kitchen appliances, and medical devices.

- Q: Can stainless steel sheets be used for fire escapes?

- Yes, stainless steel sheets can be used for fire escapes. Stainless steel is known for its high strength, corrosion resistance, and durability, making it suitable for fire escape applications. It can withstand high temperatures and is not easily affected by fire or heat, ensuring the safety and reliability of fire escapes.

- Q: Comparison of three properties of aluminium plate, stainless steel plate and cold rolled plate?

- Stainless steel plate material is hard, not easy to shape, the color is monotonous, but the color is bright, not distortion;

Send your message to us

304 316L 430 201 Inox Stainless Steel Coil/Sheet/Plate !!!

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2 m.t.

- Supply Capability:

- 5000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords