APP/SBS Basement Waterproofing Membrane

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2000 m²

- Supply Capability:

- 200000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

product description:

Item | APP/SBS Basement Waterproofing Membrane | |||||

Brand | CNBM | |||||

Grade | First | Second | ||||

Base | PY | G | PYG | |||

Cover | PE | S | M | PET | ||

Thickness | 2/2.5/3/3.5/4mm | |||||

Color | Black PE film | Yellow/Green/Red/Other Fine Sand | Grey/Green/Red/Other Mineral/Grains/Flakes | Aluminium Foil | ||

Notes | PY------Polyester Base G------Glassfibre Base PYG------Glassfibre Reinforced Polyester Base | |||||

Characteristic

a)Good impermeability

b)SBS modified bitumen membrane is specially being applied in the cold area with low temperature

c)Good performance in anti-puncture, anti-broker, anti-resistance, anti-erosion, anti-mildew, anti-weathering

d)Possess good tensile strength, elongation rate and size stability which could be well suited the substrate distortion and crack

Applicable scope

Suitable for civil building roofing, underground, bridge, parking, pool, tunnel in the line of waterproofing and dampproof, especially for the building under high temperature. According the roofing engineering stipulation, APP modified bitumen membrane could be used in the Grade I civil building and industrial building which has special waterproofing requirement

There are two methods in application

a) One way is by heating and melting method.Heat the polyethylene film of the membrane and roof deck surface by heating and melting method to be nearly melted (not flowing),then install the membrane filly bonded to the roof deck with overlaps of 5-10cm.

b) The other way is by cold adhesive method.Pour the cold adhesive homogeneously on the roof deck, then roll the membrane to install it to be fully sticked to roof deck.

By heating and melting method and by cold adhesive can be used in alternation in application as requested.

c)After application,a full serious inspection is required to sure no air bubble,no falling away.etc. to guarantee the waterproof life.

Attentions for construction

Construction shall not be carried out in rain, snow or over 5 degree wind weather; Thereshall be sufficient safety protective facilities in construction site, place firefighting devices according to stipulations

1)Clean the substrate using broom or high pressure dusty cleaner

2)Apply primer

3)Heat the membrane bottom using a high temperature flame gun

4)Push forward while the primer and membrane oil melted

5)Use a roller to push hard the membrane surface to ensure it stick firmly

Technical parameter

| Item | Specifications | ||||||||

| Geotextile Unit Weight (g/m²) | 300 | 500 | 600 | 700 | 800 | 900 | 1000 | 1100 | |

| Geomembrane Thickness (mm) | 0.25-0.35 | 0.30-0.50 | |||||||

| Nominal Fracture Strength (KN/m) | 2.50 | 7.50 | 10 | 12 | 14 | 16 | 18 | 20 | |

| Breaking Strength (KN/m,≥,LD/TD) | 2.50 | 7.50 | 10 | 12 | 14 | 16 | 18 | 20 | |

| Standard Intensity Corresponding Elongation Rate (%) | 30~100 | ||||||||

| CBR Burst Strength (KN,≥) | 0.70 | 1.50 | 1.90 | 2.20 | 2.50 | 2.80 | 3.00 | 3.20 | |

| Longitudinal Tear Strength (KN,≥) | 0.05 | 0.25 | 0.32 | 0.40 | 0.48 | 0.56 | 0.62 | 0.70 | |

| Hydrostatic Pressve (Mpa) | See List Below | ||||||||

| Peel Strength (N/cm,≥) | 6 | ||||||||

| Vertical Permeability Coefficient (cm/s) | According to design or contract mentioned. | ||||||||

| Width Variation (%) | -1.00 | ||||||||

| Item | Geomembrane Thickness (mm) | ||||||||

| 0.20 | 0.30 | 0.40 | 0.50 | 0.60 | 0.70 | 0.80 | 1.00 | ||

| Hydrostatic Pressve (Mpa) | One geotextiles with one geomembrane | 0.40 | 0.50 | 0.60 | 0.80 | 1.00 | 1.20 | 1.40 | 1.60 |

| Two geotextiles with one geomembrane | 0.50 | 0.60 | 0.80 | 1.00 | 1.20 | 1.40 | 1.60 | 1.80 | |

Our Services

1.If you need some advises for the waterproof construction, we have the best engineer to serve you.

2.We send the free samples to you by freight collect.

3.We will guarantee the quality and the competitive price.

4.We will give you the best packaging and safe shipping.

5.If any problem, we will always be right here waiting for you.

Product usage of pe compound waterproof membrane

The products are widely used in projects of compound geomembrane impervious

product show

Product line&test

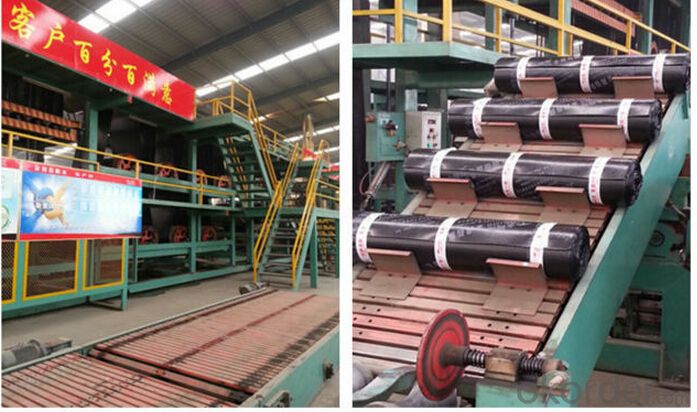

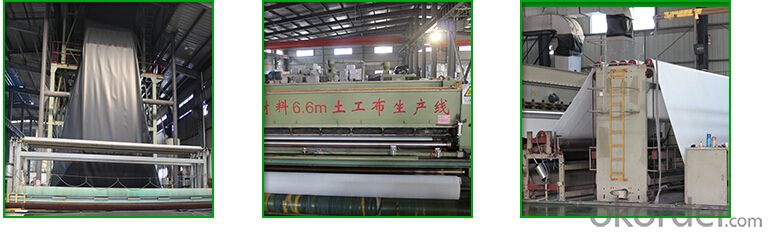

♦Product line

From raw materials to finished products, every process is tested and controlled professionally and seriously by our professional machines and person.

Professional test machines ensure the products qualified roduct certifications

roduct certifications

Inquiry Note

How to send an effective inquiry for saving your time?

Packaging & Shipping

Factory show

FAQ

- Q: Can a waterproofing membrane be used for solar panel installations?

- Indeed, the utilization of a waterproofing membrane in solar panel installations is not only possible but highly recommended. It is common practice to incorporate a waterproofing membrane into the installation process in order to safeguard the roof or other surfaces beneath the solar panels from water-related harm. The primary function of a waterproofing membrane is to serve as a barrier, preventing water infiltration into the underlying structure. This, in turn, ensures the integrity and security of the solar panel installation, which is of utmost significance considering their typical placement on rooftops, where they are exposed to various weather conditions. By incorporating a waterproofing membrane, the longevity of the solar panels is prolonged, and any potential issues arising from water are effectively mitigated, thus preserving their optimal performance.

- Q: Can a waterproofing membrane be applied on curved surfaces?

- Indeed, curved surfaces can indeed be coated with a waterproofing membrane. In reality, waterproofing membranes are designed to possess flexibility and adaptability, which render them suitable for usage on a variety of shapes and contours, including curved surfaces. These membranes are typically constructed from materials like modified bitumen, polyurethane, or rubber, all of which possess exceptional properties of elongation and flexibility. Thus, they can be easily shaped and stretched to conform to curved surfaces without compromising their waterproofing abilities. Consequently, structures featuring curved components like roofs, balconies, tunnels, and tanks can be effectively waterproofed. However, proper installation techniques and specialized tools may be necessary to ensure appropriate adherence and complete coverage on curved surfaces. Nevertheless, with the appropriate expertise and materials, successful application of waterproofing membranes on curved surfaces can be achieved.

- Q: Can a waterproofing membrane be used for theaters or concert halls?

- Theaters and concert halls can benefit greatly from the use of waterproofing membranes. These membranes are commonly employed in construction projects to safeguard buildings against water damage by preventing water infiltration. They are applied to various surfaces, including walls, floors, and roofs, creating a barrier that stops water from seeping through. In the case of theaters and concert halls, where the protection of the building structure and equipment is of utmost importance, waterproofing membranes can be extremely advantageous. They play a crucial role in preventing water damage to delicate equipment like audiovisual systems, lighting fixtures, and musical instruments. Furthermore, these membranes ensure a dry and comfortable environment for both performers and audience members by preventing water leakage and moisture buildup. In conclusion, the use of a waterproofing membrane in theaters or concert halls guarantees the longevity and functionality of the building, creating a safe and enjoyable experience for all involved.

- Q: Is a waterproofing membrane compatible with different types of adhesives?

- Yes, a waterproofing membrane is generally compatible with different types of adhesives. However, it is essential to ensure that the adhesive being used is suitable for the specific type of waterproofing membrane being installed. Different waterproofing membranes may have varying compatibility with different adhesives due to variations in their composition and surface properties. It is recommended to consult with the manufacturer or supplier of both the waterproofing membrane and the adhesive to determine their compatibility and suitability for the intended application. Additionally, following the manufacturer's instructions and guidelines for both the membrane and adhesive will help ensure proper installation and long-term performance.

- Q: How long do waterproofing membranes last?

- The lifespan of waterproofing membranes can differ based on a variety of factors including the type of membrane utilized, the quality of installation, environmental conditions, and maintenance practices. Typically, high-quality waterproofing membranes have a lifespan ranging from 10 to 50 years. As an illustration, bituminous membranes, commonly employed in roofing applications, generally last around 20 to 30 years. Conversely, more advanced synthetic membranes like PVC or TPO can endure for up to 40 years or possibly longer. Nevertheless, it is essential to recognize that these estimates are contingent upon optimal conditions and regular maintenance. Factors such as exposure to extreme weather, improper installation, insufficient maintenance, or physical damage can significantly diminish the lifespan of the membranes. Consequently, it is vital to seek guidance from professionals and adhere to the manufacturer's maintenance recommendations in order to ensure the longevity of the waterproofing membranes.

- Q: Does a waterproofing membrane provide any additional structural reinforcement?

- No, a waterproofing membrane does not provide any additional structural reinforcement. Its primary purpose is to prevent water penetration and protect the underlying structure from moisture damage. Structural reinforcement typically requires other methods such as steel reinforcement, concrete additives, or structural members like beams and columns.

- Q: Can a waterproofing membrane be used for bridges or parking decks?

- Bridges or parking decks can benefit from the use of a waterproofing membrane. These membranes are specifically designed to safeguard structures from water damage and are commonly employed in construction projects for this purpose. Since bridges and parking decks are exposed to various weather conditions, such as rain, snow, and ice, which can cause concrete and steel components to deteriorate, it is important to apply a waterproofing membrane to prevent moisture from seeping in. This will help prevent corrosion, cracking, and other forms of deterioration. Moreover, waterproofing membranes offer additional advantages like improved durability, increased lifespan, and reduced maintenance costs for these structures. Therefore, using a waterproofing membrane is highly recommended to ensure the long-term integrity and functionality of bridges and parking decks.

- Q: Can waterproofing membranes be used on concrete fountains?

- Concrete fountains, which are frequently subjected to water and susceptible to leaks and moisture damage, can benefit from the application of waterproofing membranes. These membranes serve as a barrier that prevents water penetration and safeguards the structure of the fountain. Designed to be flexible, durable, and resistant to water, waterproofing membranes provide an optimal solution for concrete fountains. They can be applied to both the interior and exterior surfaces of the fountain, ensuring comprehensive protection against water damage. By utilizing waterproofing membranes, the lifespan of the concrete fountain can be prolonged, and maintenance expenses can be minimized.

- Q: Are waterproofing membranes resistant to frost damage?

- Waterproofing membranes, in general, exhibit resistance towards frost damage. These membranes are specifically crafted to endure diverse weather conditions, which include freezing temperatures. They typically comprise modified bitumen, PVC, EPDM, or TPO, materials renowned for their exceptional frost and environmental resistance. These materials are engineered to maintain their flexibility and elasticity, even in low temperatures, ensuring the preservation of the waterproofing membrane's effectiveness in preventing water infiltration. Furthermore, meticulous installation methods and regular maintenance can augment the waterproofing membranes' resistance to frost damage.

- Q: Can waterproofing membranes be used on concrete planters?

- Yes, waterproofing membranes can be used on concrete planters. Waterproofing membranes are designed to create a barrier against water, preventing it from seeping through the concrete and causing damage. By applying a waterproofing membrane to the concrete planter, you can ensure that the planter remains watertight, preventing water from leaking out and potentially damaging the surrounding area. This can be especially beneficial for planters located indoors or in areas where water leakage could cause structural damage or create a mess. Additionally, waterproofing membranes can also help protect the concrete from freeze-thaw cycles, which can cause cracking and deterioration over time. Overall, by using waterproofing membranes on concrete planters, you can extend their lifespan and maintain their functionality for a longer period of time.

Send your message to us

APP/SBS Basement Waterproofing Membrane

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2000 m²

- Supply Capability:

- 200000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords