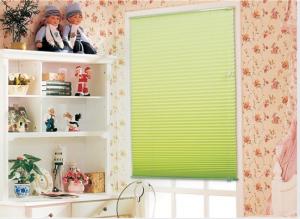

Soft vertical blinds new styles curtain blind curtain

- Loading Port:

- Ningbo

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1000 m

- Supply Capability:

- 500000 m/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Speicification of sunscreen blind curtains roller blind for day and night zebra curtain :

Material : PVC

Colors: different colors are available

Size : 2.8m x30m

Edge: high difination and never loose edge

Description of Soft vertical blinds new styles curtain

1. It was created on the base of traditional vertical blind,not only have the function of controlling the light,but possess the advantage of soft fabrics.

2. These products are towards to high-end market, with broad market and high profits, we will also protct your markt at the beginning, less the pressure of the competition.

3. Supply exquisite sample books for your promotion.

4. Provide service of products consultation and repurchasing components, such as accessaries, mould, CD for ready made market.

Specifications

Soft vertical blind fabric

Composition:80%polyester + 20% RM

Weight per M2: 205g +/- 5%

Color fastness: 7-8 grade

Width:280c

Packing & delivery of sunscreen blind curtains roller blind for day and night zebra curtain :

Packing : 30m per roll, inner with plastic tube then into plastic bag .

Details: strong enough and waterproof

Delivery time : 20days after confirmed orders.

Advantage of our products vertical blind curtains :

1. Rich series and various colors: with the concise and fashionabl design, Hanas is widely used in villa, star hotel, coffee bar, western restaurant.

2, Material and machines: Korea yarn and SMIT weaving machine from Italy.

3. Environtal friendly: passed SGS environmental and ecological testing.

4. Quality assured: professional Q'C team, 5 senior engineers with 20 more years' experience.

5. Sprite Service: products' consultation, exquiste catalogues, components purchasing, assembling traning, etc.

6. Delivery guarantee: within 25 days after receiving the prepayment for first order.

- Q: Can plastic parts in home appliances be affected by exposure to high humidity?

- Yes, plastic parts in home appliances can be affected by exposure to high humidity. High humidity can cause the plastic to absorb moisture, leading to warping, discoloration, and degradation over time. It can also accelerate the growth of mold and mildew, posing a risk to both the appliance's functionality and the user's health. Therefore, it is important to protect plastic parts in home appliances from prolonged exposure to high humidity.

- Q: How does plastic contribute to the lightweight nature of home appliances?

- Plastic contributes to the lightweight nature of home appliances due to its inherent low density and ability to be molded into complex shapes, allowing for the creation of lighter components and overall lighter appliances.

- Q: Are there any specific guidelines for using home appliances with plastic parts in outdoor settings?

- Yes, there are some specific guidelines to consider when using home appliances with plastic parts in outdoor settings. Firstly, always check the manufacturer's instructions or user manual to see if the appliance is designed for outdoor use. If it is not explicitly mentioned, it is generally advisable to avoid exposing these appliances to extreme weather conditions such as rain, direct sunlight, or extreme temperatures. Additionally, it's important to protect the appliance from moisture, dust, and debris by using appropriate covers or enclosures. Regular cleaning and maintenance can also help prolong the lifespan of these appliances when used outdoors.

- Q: What are the considerations for using lightweight plastic in home appliances?

- There are several considerations when using lightweight plastic in home appliances. Firstly, the durability of the plastic is crucial to ensure that the appliance can withstand regular use and potential impacts. Additionally, the plastic must be heat resistant and able to withstand high temperatures without deforming or melting. The cost-effectiveness of the plastic is also important, as it should be a cost-efficient option compared to alternative materials. Lastly, the environmental impact of the plastic, including its recyclability and potential for waste reduction, should be taken into account to ensure sustainable manufacturing and disposal practices.

- Q: What are the typical manufacturing processes for home appliance plastics?

- The typical manufacturing processes for home appliance plastics include injection molding, blow molding, and thermoforming. Injection molding involves injecting molten plastic into a mold cavity and allowing it to cool and solidify, creating the desired shape. Blow molding is used to create hollow plastic parts by blowing air into a molten plastic tube, expanding it to match the shape of the mold. Thermoforming involves heating a plastic sheet and shaping it using a mold and vacuum or pressure, resulting in a formed part. These processes are commonly used in the production of various home appliances such as refrigerators, washing machines, and microwave ovens.

- Q: Are there any limitations in terms of chemical resistance for plastic parts in home appliances?

- Yes, there are limitations in terms of chemical resistance for plastic parts in home appliances. While many plastics exhibit good resistance to common household chemicals, they may not be suitable for exposure to certain aggressive chemicals or solvents. Certain acids, alkalis, and strong cleaning agents can cause deterioration, discoloration, or even deformation of plastic parts. It is important to consider the specific chemical environment and select plastic materials with appropriate resistance properties to ensure the longevity and performance of plastic components in home appliances.

- Q: Are there any health concerns with plastic parts in electric toothbrush chargers?

- Yes, there are potential health concerns associated with plastic parts in electric toothbrush chargers. Some plastics, such as BPA (bisphenol A), may contain chemicals that can leach into the environment and potentially disrupt hormone levels in the body. However, many electric toothbrush chargers are made from BPA-free plastics, which significantly reduces the risk. It is always advisable to check the materials used and opt for chargers made from safer plastics to minimize any potential health risks.

- Q: Can plastic parts in home appliances be affected by pests or insects?

- Yes, plastic parts in home appliances can be affected by pests or insects. Pests and insects often chew on or burrow into plastic materials, causing damage or compromising the functionality of the appliance. It is important to take necessary measures to prevent infestations and protect plastic parts from potential pest-related issues.

- Q: Are there any regulations or standards for home appliance plastics?

- Yes, there are regulations and standards for home appliance plastics. These regulations are implemented to ensure the safety, performance, and environmental impact of home appliances. Standards such as UL and IEC establish criteria for materials used in the manufacturing of appliances, including plastics, to meet specific safety requirements. Additionally, regulations like RoHS restrict the use of hazardous substances in electronics and electrical appliances, including certain types of plastics. These regulations and standards are in place to safeguard consumers and promote sustainable manufacturing practices.

- Q: How do manufacturers ensure the durability of plastic parts in home appliances?

- Manufacturers ensure the durability of plastic parts in home appliances through various methods such as selecting high-quality materials, conducting rigorous testing, and implementing efficient manufacturing processes. They carefully choose durable plastic materials that can withstand the expected wear and tear, impact, and temperature variations. Additionally, manufacturers subject the plastic parts to extensive testing, including stress tests and simulated usage scenarios, to ensure their strength and longevity. They also optimize the manufacturing processes to ensure precise molding, proper assembly, and adequate reinforcements, to enhance the durability of the plastic parts in home appliances.

Send your message to us

Soft vertical blinds new styles curtain blind curtain

- Loading Port:

- Ningbo

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1000 m

- Supply Capability:

- 500000 m/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches