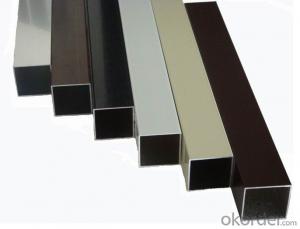

Anodized Aluminum Square Tubes for Doors and Windows Furniture

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 500 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specifications

anodized aluminum square tube

1.Alloy 2014 2024 7020 6061 7075

2.Temper:F O T4 T5 ,T6

3.Out diameter:4.5-610 mm

Product name | anodized aluminum square tube | |

Shape | Round, oval, square, rectangle | |

Size | Out Diameter | 4.5-610 mm |

Wall Thickness | 1-110 mm | |

Length | According to customer’s requirement | |

Alloy | 1070-1100 3003 5052 5754 5083 5056 2017 2014 2A12 2024 6060 6082 6061 6063 7050 7075 7005 7020 7A09 | |

Temper | F, O, T4, T5, T6 | |

Standard | GB /ASTM | |

Surface Treatment | 1.mill finished 2.anodizing:shiny anodized,frosty anodized 3.electrophoretic coating:shiny elecyrophoretic,frosty electrophoretic 4.electrophoretic color powder coating:normal color,special color. 5.fluorocarbon powder spraying:normal color,special paper 6.polished 7.wood grain coating: special paper, special paper

| |

Application | Construction, decoration and industry | |

Origin | Chongqing ,China | |

Port | Chongqing or Shanghai | |

MOQ | 2 Metric Tons | |

Delivery Time | 30 work days after deposit or L/C | |

Payment Terms | T/T, irrevocable L/C at sight. | |

Supply Ability | 5000 Metric Ton / Month | |

Packaging | Foam paper and carton box package,kraft paper package,plastic film and the plastic wrap package are optional,or as requested. | |

- Q: Is it possible to utilize aluminum profiles in the construction or structure of commercial buildings and factories?

- <p>Yes, aluminum profiles are commonly used in commercial buildings and factories due to their strength, durability, and lightweight properties. They are ideal for constructing frameworks, window and door frames, and support structures. The corrosion resistance of aluminum also makes it suitable for industrial environments where exposure to harsh chemicals or weather conditions is a concern. Additionally, aluminum profiles are easy to maintain and can be recycled, contributing to the sustainability of construction projects.</p>

- Q: Are aluminum profiles recyclable and can they be used again in flooring applications?

- <p>Yes, aluminum profiles can be recycled and reused in flooring applications. Aluminum is a highly recyclable material, with recycling processes that retain its properties without loss in quality. This makes it an environmentally friendly choice for flooring as it reduces waste and conserves resources. Recycled aluminum can be used to create new profiles for flooring systems, maintaining strength and durability while offering a sustainable solution.</p>

- Q: What are the different surface patterns available for aluminum profiles?

- Some of the different surface patterns available for aluminum profiles include brushed, anodized, powder coated, polished, and textured finishes.

- Q: Is it possible to utilize aluminum profiles in interior design projects?

- <p>Yes, aluminum profiles can be used for interior design. They are popular for their strength, durability, and modern aesthetic. Aluminum profiles are lightweight, easy to install, and resistant to corrosion, making them suitable for various applications such as window frames, door frames, shelving systems, and decorative elements. They can be powder-coated or anodized to achieve different colors and finishes, allowing for a wide range of design flexibility.</p>

- Q: This question asks about the various types of aluminum profiles that are utilized specifically for constructing wall frames.

- <p>Aluminum profiles for wall frames come in various types, each serving specific purposes. Common types include: 1) Structural profiles, which provide the main support and strength to the frame; 2) Cover profiles, used to conceal joints and fasteners, enhancing the aesthetic appeal; 3) Insulation profiles, designed to provide thermal insulation; 4) Glazing profiles, used to hold glass or other transparent materials in place; 5) Corner profiles, for joining two walls at a right angle; 6) Sealing profiles, to ensure weatherproofing and airtightness; and 7) Special profiles, tailored for unique architectural designs or specific functions. Each type is chosen based on the structural requirements, design aesthetics, and performance needs of the wall system.</p>

- Q: Are aluminum profiles suitable for use in sustainable or eco-friendly construction projects?

- <p>Yes, aluminum profiles can be used for green building projects. They are valued for their recyclability, which contributes to sustainability. Aluminum is lightweight, strong, and requires less energy to produce and transport compared to other materials like steel. Additionally, aluminum's durability can lead to a longer lifespan, reducing the need for frequent replacements and thus minimizing waste. Moreover, aluminum can be used in energy-efficient designs, such as in window frames that provide better insulation, further enhancing the green credentials of a building.</p>

- Q: Can aluminum profiles be used for transportation applications?

- Yes, aluminum profiles can be used for transportation applications. Aluminum is a lightweight and durable material, making it ideal for various transportation purposes. It is commonly used in the construction of vehicles, including cars, trucks, trains, airplanes, and ships. Aluminum profiles can be used to create strong and rigid structures, reducing the overall weight of the vehicle, which in turn improves fuel efficiency and reduces emissions. Additionally, aluminum is resistant to corrosion, making it suitable for outdoor and maritime applications. The versatility and strength of aluminum profiles make them a popular choice in the transportation industry.

- Q: What specific considerations or criteria must be met when using aluminum profiles in the construction of high-rise buildings?

- <p>Yes, there are special requirements for using aluminum profiles in high-rise buildings. These include high strength and load-bearing capacity to withstand the weight and wind forces. Durability is crucial to resist corrosion and weathering over time. Fire resistance is also important for safety. Additionally, aluminum profiles must comply with building codes and regulations specific to high-rise structures. They should also have good thermal insulation properties to maintain energy efficiency and comfort. Lastly, aesthetic considerations are important as the profiles contribute to the building's exterior appearance.</p>

- Q: This question asks about the various thicknesses and grades of aluminum profiles that are specifically used for roofing purposes.

- <p>Aluminum profiles for roofing come in different thicknesses and grades, which determine their strength and suitability for various applications. Common thicknesses range from 0.5mm to 1.5mm, with 0.5mm and 0.6mm being the most common for residential roofing. For commercial and industrial applications, thicknesses of 0.8mm to 1.5mm are often used due to their increased load-bearing capacity. Grades of aluminum profiles are typically classified based on their alloy composition, with 1100, 3003, 5005, and 6061 being the most common. Each grade has different properties, such as corrosion resistance, formability, and strength, which make them suitable for specific roofing applications. For instance, 3003-grade aluminum is widely used for roofing due to its good formability and moderate strength. The choice of thickness and grade depends on the specific requirements of the roofing project, such as the expected load, environmental conditions, and aesthetic preferences.</p>

- Q: This question asks about potential health hazards related to the use of aluminum profiles in construction.

- <p>There are minimal health risks associated with using aluminum profiles in building construction. Aluminum is a non-toxic metal and does not emit harmful substances. However, during the manufacturing process, if not properly controlled, there might be concerns related to dust and fumes. Additionally, aluminum can react with other materials, potentially causing corrosion or weakening the structure. It's important to ensure that aluminum profiles are used in accordance with safety standards and guidelines to mitigate any potential risks.</p>

Send your message to us

Anodized Aluminum Square Tubes for Doors and Windows Furniture

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 500 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords