Anodized Aluminum Sheets for Aircraft and Curtain Wall System

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 100000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

1.Structure of Anodised Aluminum Rolls for Curtain Wall System

Aluminum Sheets are strengthened and cut from raw materials with different alloys, such as AA5005, AA5052, etc. They are easy for processing in different shapes, good in intensity and can be quickly installed. Aluminium Sheets for Energy Saving Curtain Walls are good in energy saving, weather resistance, fire resistance, easy for maintenance and with many colors.

Aluminium Sheets for Energy Saving Curtain Walls are widely used in construction of metal walls, metal ceilings, car decoration, advertizing panels, etc.

2.Main Features of Anodised Aluminum Rolls for Curtain Wall System

•High intensity

•Easy to be processed and shaped

•Weather resistance

•Anti-pollution & environment protection

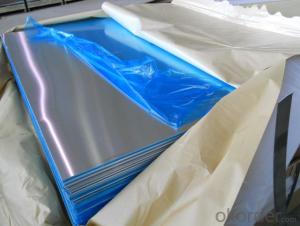

3. Anodised Aluminum Rolls for Curtain Wall System Images

4.Specification of Anodised Aluminum Rolls for Curtain Wall System

Alloy Number | AA5XXX |

Temper | H12, H14, H16, H18, H22, H24, H26, H32, HO, F |

Thickness | 0.1mm – 500mm |

Width | 10mm- 2200mm |

Standard | GB/T3880-2006, ASTM, ISO, EU standard |

5.FAQ

A.What about inspections to guarantee quality?

For each order for Aluminum Sheets with Mill Finished Surface AA5XXX, we will arrange strict inspection for raw materials, inspection during production and inspection for finished goods.

With requirement of customers, we also can arrange the third party inspection.

B.What about delivery?

We will put order for Aluminum Sheets with Mill Finished Surface AA5XXX in production schedule after order gets confirmed against copy of TT or L/C. Normally it takes about one month for production. Exact shipment schedule is different based on different sizes and quantity.

C.What is the MOQ?

5 tons for each size.

D. Where have you exported aluminium sheets?

We have exported aluminum sheets to many countries. Main markets include South East Asia, Middle East, North America, South America, etc.

- Q: where can I sell aluminum tabs from aluminum cans in Palmdale, Califronia?

- Scrap yards and recyclers.

- Q: Can aluminum sheets be used in outdoor environments?

- Indeed, aluminum sheets are capable of being utilized in outdoor settings. Aluminum, a material that is both highly adaptable and enduring, proves to be a fitting choice for outdoor uses. Its exceptional resistance to corrosion renders it well-equipped to endure environmental factors like rain, snow, and UV radiation. Moreover, aluminum sheets are characterized by their lightweight nature and structural robustness, rendering them appropriate for a multitude of outdoor endeavors, including roofing, siding, and cladding. Furthermore, aluminum's non-combustible nature makes it a secure option for outdoor environments. All in all, aluminum sheets offer a dependable and enduring solution for outdoor applications.

- Q: Can aluminum sheets be used in food packaging?

- Indeed, aluminum sheets find widespread application in the realm of food packaging. The utilization of aluminum in this context is prevalent owing to its exceptional capability to shield food from detrimental elements like light, oxygen, moisture, and other external agents that may cause spoilage or contamination. Notably, aluminum sheets possess the qualities of being lightweight, long-lasting, and resistant to corrosion, rendering them perfectly suitable for an array of food packaging formats, including foil wraps, containers, trays, and pouches. Moreover, the recyclability of aluminum further solidifies its status as an eco-friendly option for food packaging.

- Q: The minimum thickness of aluminum curtain wall is 2, 5mm or 3mm?

- JGJ133-2001 3.3.10Generally, aluminum plate refers to aluminum veneer;The thickness requirements of different metal plates are specified in 133 Li and 3.3 bars

- Q: How are aluminum sheets different from aluminum plates?

- Aluminum sheets and aluminum plates differ primarily in terms of thickness and applications. Aluminum sheets are typically thinner, ranging from 0.2mm to 6mm in thickness, whereas aluminum plates are thicker, usually starting from 6mm and going up to several inches thick. Aluminum sheets are commonly used for general purposes such as packaging, signage, and roofing due to their lightweight nature and flexibility. They are often bent, formed, and cut into various shapes and sizes to fulfill specific requirements. On the other hand, aluminum plates are typically used in applications that require higher strength and durability. With their greater thickness, they provide enhanced structural integrity and are commonly utilized in industries such as aerospace, automotive, and construction. Aluminum plates can withstand heavy loads and are often used as structural components in buildings, aircraft, and machinery. In summary, the main differences between aluminum sheets and aluminum plates lie in their thickness and the specific applications they are suited for. Sheets are thinner and more flexible, suitable for general purposes, while plates are thicker and stronger, ideal for heavy-duty applications that require structural integrity.

- Q: What's the standard thickness of aluminum sheet?

- the thickness of tobacco aluminum foil and red wine bottle cap is designed according to customers demands and manufacturer has no stated specification.

- Q: I was looking at Audioque subs earlier and what is the difference between copper and aluminum coiled subs. do aluminum last longer or something?

- Aluminum is stronger than copper. It takes more aluminum to make something strong as steel. However copper conducts electricty ans signals better than aluminum. People are switching to aluminum cause its cheaper.

- Q: Where else besides deodorant can we find aluminum?

- aluminum foil

- Q: (2) when aluminium foil is dipped in mercury for a short time and then placed in water a reaction is seen to occur with hydrogen gas being one of the products.?????

- Aluminium is very reactive in air and forms a protective oxide coating. This protects it when placed in water as aluminium oxide is unreactive with water. When immersed in mercury the oxide coating is removed and therefore the aluminium itself reacts when the cleaned aluminium metal is immersed in water.

- Q: Are 101 aluminum sheets suitable for aerospace tooling?

- No, 101 aluminum sheets are not suitable for aerospace tooling.

Send your message to us

Anodized Aluminum Sheets for Aircraft and Curtain Wall System

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 100000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords