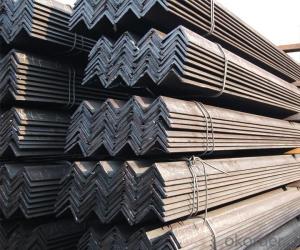

Angle Steel Hot Rolled 20MM-250MM Or Unequal Angle Steel

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Description:

OKorder is offering high quality Angle Steel Hot Rolled 20MM-250MM Or Unequal Angle Steel at great prices with worldwide shipping. Our supplier is a world-class manufacturer of steel, with our products utilized the world over. OKorder annually supplies products to European, North American and Asian markets. We provide quotations within 24 hours of receiving an inquiry and guarantee competitive prices.

Product Applications:

According to the needs of different structures, Angle can compose to different force support component, and also can be the connections between components. It is widely used in various building structures and engineering structures such as roof beams, bridges, transmission towers, hoisting machinery and transport machinery, ships, industrial furnaces, reaction tower, container frame and warehouse etc

Product Advantages:

OKorder's Angle Steel Hot Rolled 20MM-250MM Or Unequal Angle Steel are durable, strong, and resist corrosion.

Main Product Features:

· Premium quality

· Prompt delivery & seaworthy packing (30 days after receiving deposit)

· Corrosion resistance

· Can be recycled and reused

· Mill test certification

· Professional Service

· Competitive pricing

Product Specifications:

Manufacture: Hot rolled

Grade: Q195 – 235

Certificates: ISO, SGS, BV, CIQ

Length: 6m – 12m, as per customer request

Packaging: Export packing, nude packing, bundled

Sizes: 25mm-250mm | ||||||||||||

a*t | ||||||||||||

25*2.5-4.0 | 70*6.0-9.0 | 130*9.0-15 | ||||||||||

30*2.5-6.6 | 75*6.0-9.0 | 140*10-14 | ||||||||||

36*3.0-5.0 | 80*5.0-10 | 150*10-20 | ||||||||||

38*2.3-6.0 | 90*7.0-10 | 160*10-16 | ||||||||||

40*3.0-5.0 | 100*6.0-12 | 175*12-15 | ||||||||||

45*4.0-6.0 | 110*8.0-10 | 180*12-18 | ||||||||||

50*4.0-6.0 | 120*6.0-15 | 200*14-25 | ||||||||||

60*4.0-8.0 | 125*8.0-14 | 250*25 | ||||||||||

FAQ:

Q1: How do we guarantee the quality of our products?

A1: We have established an advanced quality management system which conducts strict quality tests at every step, from raw materials to the final product. At the same time, we provide extensive follow-up service assurances as required.

Q2: What makes stainless steel stainless?

A2: Stainless steel must contain at least 10.5 % chromium. It is this element that reacts with the oxygen in the air to form a complex chrome-oxide surface layer that is invisible but strong enough to prevent further oxygen from "staining" (rusting) the surface. Higher levels of chromium and the addition of other alloying elements such as nickel and molybdenum enhance this surface layer and improve the corrosion resistance of the stainless material.

Q3: Can stainless steel rust?

A3: Stainless does not "rust" as you think of regular steel rusting with a red oxide on the surface that flakes off. If you see red rust it is probably due to some iron particles that have contaminated the surface of the stainless steel and it is these iron particles that are rusting. Look at the source of the rusting and see if you can remove it from the surface.

- Q: Can steel angles be used for framing in residential construction?

- Yes, steel angles can be used for framing in residential construction. They are commonly used to provide structural support and stability in various applications, including framing walls, roofs, and floors. Steel angles offer strength, durability, and versatility, making them a suitable choice for residential framing projects.

- Q: Can steel angles be used for foundation supports?

- Yes, steel angles can be used for foundation supports. Steel angles provide structural support and stability, making them suitable for various construction applications, including foundation supports.

- Q: How do you specify steel angles in a construction project?

- In a construction project, steel angles are typically specified by indicating the dimensions of the angle and the type of steel used. This includes specifying the length and width of the angle, as well as the thickness of the steel. Additionally, the type of steel, such as A36 or A572, may be specified to ensure the desired strength and durability.

- Q: How do you protect steel angles from corrosion?

- Steel angles can be protected from corrosion in various ways. One of the most commonly used methods is the application of a protective coating, such as paint or a specialized corrosion-resistant coating. This creates a barrier between the steel and its surroundings, preventing moisture and corrosive agents from reaching the metal surface. Another effective approach is to galvanize the steel angles. This involves coating the steel with a layer of zinc, which acts as a sacrificial anode. Instead of the steel corroding, the zinc sacrifices itself, providing long-lasting protection against rust and corrosion. Regular maintenance is also crucial for corrosion prevention. It is important to regularly clean the surface to remove dirt, debris, and other contaminants that can accelerate corrosion. Additionally, inspecting the steel angles for any signs of damage or wear and promptly repairing or replacing any compromised areas can help stop corrosion from spreading. Using stainless steel angles is another option for corrosion protection. Stainless steel contains a significant amount of chromium, which forms a passive layer on the surface when exposed to oxygen. This passive layer acts as a protective barrier against corrosion, making stainless steel angles highly resistant to rust and corrosion in various environments. Lastly, ensuring proper drainage and ventilation around steel angles is essential to prevent the accumulation of moisture, which can contribute to corrosion. By employing proper design and installation techniques that minimize contact with water and moisture, the lifespan of steel angles can be significantly extended, and the risk of corrosion reduced.

- Q: What are the different methods of impact testing for steel angles?

- There are several methods of impact testing that can be used to assess the toughness and resistance of steel angles. These methods include the Charpy V-notch test, the Izod test, and the drop weight test. 1. Charpy V-notch Test: This is one of the most commonly used methods for impact testing. In this test, a notched specimen of the steel angle is placed in a pendulum hammer. The hammer is released, swinging down and striking the specimen. The amount of energy absorbed by the specimen before it fractures is measured and used to determine the impact toughness of the material. 2. Izod Test: Similar to the Charpy V-notch test, the Izod test involves using a pendulum hammer to strike a notched specimen of the steel angle. However, in this test, the specimen is clamped vertically, while the hammer strikes it horizontally. The energy absorbed by the specimen is measured and used to evaluate its impact resistance. 3. Drop Weight Test: This method involves dropping a weight onto a specimen of the steel angle from a certain height. The specimen is usually supported on a solid base, and the impact energy is calculated based on the weight and the height of the drop. The deformation and fracture behavior of the specimen are then analyzed to determine its impact toughness. These different methods of impact testing help engineers and manufacturers assess the ability of steel angles to withstand sudden impact or shock loads. By evaluating the toughness and resistance of the material, these tests provide valuable information for designing structures and selecting appropriate materials for various applications.

- Q: What are the different types of connections used for steel angles in marine applications?

- Steel angles are commonly utilized in marine applications to provide structural support and reinforcement. To ensure their stability and strength in the harsh marine environment, various types of connections are employed. The different connection methods for steel angles in marine applications include: 1. Welded Connections: Welding is widely used to connect steel angles in marine applications. This method involves melting the base metals and allowing them to cool and solidify, resulting in strong and durable connections. Welded connections are ideal for heavy-duty marine applications due to their excellent strength and durability. 2. Bolted Connections: Another commonly used method is bolted connections, which involve securing the angles together using bolts, nuts, and washers. Bolted connections offer easy installation and allow for disassembly if needed. They are suitable when adjustments or replacements of the angles are required. 3. Riveted Connections: Riveting, an older connection method, is still employed in certain marine applications. It entails using rivets, metal pins with heads, to connect the angles. The rivets are inserted through pre-drilled holes in the angles and deformed to secure them. Riveted connections offer good strength and vibration resistance, but they can be time-consuming to install compared to other methods. 4. Adhesive Connections: Adhesive bonding is a contemporary method used to connect steel angles in marine applications. This method involves utilizing high-strength adhesives to join the angles together. Adhesive connections evenly distribute stress across the connected surfaces and eliminate the need for drilling or welding. However, they require meticulous surface preparation and curing time for optimal strength. 5. Hybrid Connections: In certain cases, a combination of different connection methods may be employed for steel angles in marine applications. For instance, a welded-bolted connection may be used to enhance strength and redundancy. Hybrid connections offer the advantages of multiple connection methods while ensuring a robust and reliable connection. The choice of connection type for steel angles in marine applications depends on factors such as load requirements, environmental conditions, and project specifications. It is crucial to consider the specific needs of the application and consult with structural engineers and marine professionals to determine the most suitable connection method.

- Q: How do you calculate the moment resistance of a steel angle connection?

- To calculate the moment resistance of a steel angle connection, you need to consider factors such as the geometry of the connection, the material properties of the steel angle, and the applied loads. The moment resistance can be determined by analyzing the section properties of the angle, such as the moment of inertia and the distance from the centroid to the extreme fiber. Additionally, you need to consider the strength of the steel material, typically provided by the manufacturer. By combining these factors and using appropriate design equations or software, you can calculate the moment resistance of the steel angle connection.

- Q: What is the tensile strength of steel angles?

- The tensile strength of steel angles can vary depending on the specific grade and manufacturing process, but it is generally considered to be high.

- Q: Are steel angles corrosion-resistant?

- Yes, steel angles are corrosion-resistant due to the protective oxide layer that forms on their surface, which helps prevent rusting and degradation.

- Q: What is the process of hot rolling steel angles?

- The process of hot rolling steel angles involves a series of steps that transform raw materials into finished steel angles with specific dimensions and properties. Firstly, the raw material, which is typically a billet or a continuous casting, is heated to a temperature above its recrystallization point. This makes the steel more malleable and easier to shape. The heated billet is then fed into a rolling mill, where it passes through a series of rollers. These rollers apply pressure to the billet, causing it to deform and take the shape of an angle. The angle is determined by the shape of the rollers, which have a groove or profile that matches the desired angle dimensions. As the billet passes through the rolling mill, it undergoes a process called plastic deformation. This involves the elongation and reduction of its cross-sectional area, resulting in a longer and thinner shape. The angle's flanges, which are the vertical sides, and the web, which is the horizontal section connecting the flanges, are formed during this deformation. To maintain the desired shape and dimensions, the steel angle may pass through multiple sets of rollers, each applying pressure and further shaping the angle. This continuous rolling process ensures consistent dimensions and smooth surfaces. Once the hot rolling process is complete, the steel angles are cooled and straightened. This is typically done using water or air cooling methods. Cooling the steel rapidly helps to harden and strengthen it, while straightening ensures that the angles are free from any bends or twists. After cooling and straightening, the steel angles may undergo additional processes such as cutting to the desired length, surface treatment such as painting or galvanizing, and quality control inspections to ensure they meet the required specifications. Overall, the hot rolling process for steel angles involves heating the raw material, passing it through rolling mills to shape and deform it, cooling and straightening the angles, and finally finishing them to meet the desired specifications. This process results in high-quality steel angles that are widely used in construction, manufacturing, and various other industries.

Send your message to us

Angle Steel Hot Rolled 20MM-250MM Or Unequal Angle Steel

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords