Angle Steel, Hot Rolled Steel Angle Bars, Unequal Angle Steel

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 30000 m.t./month

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

You Might Also Like

Specifications

angle steel

1.size:25*16*3mm-200*125*18mm

2.quality:Q235,Q345,SS400,A36

3.length: 6m, 9m, 12m

4.unequal

angle steel

angle steel

(1)Material:Q235 SS400 S235JR OR ST37-2 Q345

(2)Size:25x16x3mm-200x125x18mm

(3)Certificate:ISO,CE

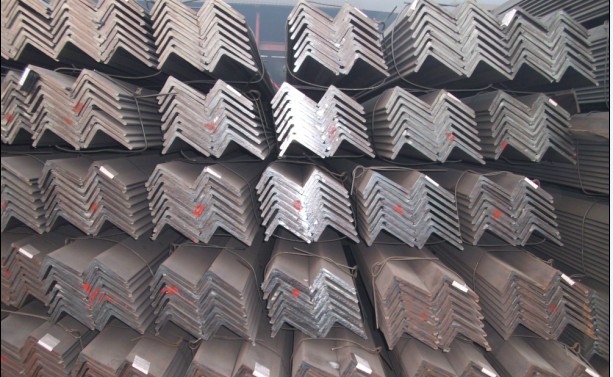

angle steel

Size of unequal angle steel

| B(mm) | b(mm) | d(mm) | Theoretic Weight(kg/m) | |

| 25 | 16 | 3 | 0.912 | |

| 25 | 16 | 4 | 1.176 | |

| 32 | 20 | 3 | 1.171 | |

| 32 | 20 | 4 | 1.522 | |

| 40 | 25 | 3 | 1.484 | |

| 40 | 25 | 4 | 1.936 | |

| 45 | 28 | 3 | 1.687 | |

| 45 | 28 | 4 | 2.203 | |

| 50 | 32 | 3 | 1.908 | |

| 50 | 32 | 4 | 2.494 | |

| 56 | 36 | 3 | 2.153 | |

| 56 | 36 | 4 | 2.818 | |

| 56 | 36 | 5 | 3.466 | |

| 63 | 40 | 4 | 3.185 | |

| 63 | 40 | 5 | 3.92 | |

| 63 | 40 | 6 | 4.638 | |

| 63 | 40 | 7 | 5.339 | |

| 70 | 45 | 4 | 3.57 | |

| 70 | 45 | 5 | 4.403 | |

| 70 | 45 | 6 | 5.218 | |

| 70 | 45 | 7 | 6.011 | |

| 75 | 50 | 5 | 4.808 | |

| 75 | 50 | 6 | 5.699 | |

| 75 | 50 | 8 | 7.431 | |

| 75 | 50 | 10 | 9.098 | |

| 80 | 50 | 5 | 5.005 | |

| 80 | 50 | 6 | 5.935 | |

| 80 | 50 | 7 | 6.848 | |

| 80 | 50 | 8 | 7.745 | |

| 90 | 56 | 5 | 5.661 | |

| 90 | 56 | 6 | 6.717 | |

| 90 | 56 | 7 | 7.756 | |

| 90 | 56 | 8 | 8.779 | |

| 100 | 63 | 6 | 7.55 | |

| 100 | 63 | 7 | 8.722 | |

| 100 | 63 | 8 | 9.878 | |

| 100 | 63 | 10 | 12.142 | |

| 100 | 80 | 6 | 8.35 | |

| 100 | 80 | 7 | 9.656 | |

| 100 | 80 | 8 | 10.946 | |

| 100 | 80 | 10 | 13.476 | |

| 110 | 70 | 6 | 8.35 | |

| 110 | 70 | 7 | 9.656 | |

| 110 | 70 | 8 | 10.946 | |

| 110 | 70 | 10 | 13.476 | |

| 125 | 80 | 7 | 11.066 | |

| 125 | 80 | 8 | 12.511 | |

| 125 | 80 | 10 | 15.474 | |

| 125 | 80 | 12 | 18.33 | |

| 140 | 90 | 8 | 14.16 | |

| 140 | 90 | 10 | 17.475 | |

| 140 | 90 | 12 | 20.724 | |

| 140 | 90 | 14 | 23.908 | |

| 160 | 100 | 10 | 19.872 | |

| 160 | 100 | 12 | 23.592 | |

| 160 | 100 | 14 | 27.247 | |

| 160 | 100 | 16 | 30.835 | |

| 180 | 110 | 10 | 22.273 | |

| 180 | 110 | 12 | 26.464 | |

| 180 | 110 | 14 | 30.589 | |

| 180 | 110 | 16 | 34.649 | |

| 200 | 125 | 12 | 29.761 | |

| 200 | 125 | 14 | 34.436 | |

| 200 | 125 | 16 | 39.045 | |

| 200 | 125 | 18 | 43.588. | |

angle steel

angle steel

- Q: Can steel angles be used for architectural detailing?

- Indeed, architectural detailing can make use of steel angles. These versatile structural elements find application in diverse architectural scenarios. They serve to provide stability and support to structures, fulfilling framing, bracing, and reinforcing purposes. Examples of steel angle implementation can be observed in architectural features like window frames, door frames, staircases, and handrails, among others. Their inherent strength and durability render them fitting for both interior and exterior architectural designs. Furthermore, steel angles can be effortlessly tailored and manufactured to meet precise design specifications, empowering architects to conceive distinctive and visually appealing architectural details.

- Q: What is the maximum allowable torsional buckling stress for a steel angle?

- The torsional buckling stress limit for a steel angle is determined by multiple factors, including the steel's material properties, the angle's geometry, and the applied load conditions. Torsional buckling occurs when a member twists due to torque, leading to instability and potential failure. To prevent this, design codes and standards offer guidelines and formulas for determining the maximum allowable stress. One example is the American Institute of Steel Construction (AISC), which provides a formula in their Steel Construction Manual for calculating torsional buckling stress. This formula considers the angle's section properties, such as the moment of inertia and radius of gyration, as well as the member's slenderness ratio and effective length. It's important to note that the maximum allowable torsional buckling stress varies based on specific design requirements and safety factors applied during the design process. Therefore, consulting relevant design codes and a structural engineer is crucial to determine the specific maximum allowable torsional buckling stress for a given steel angle in a particular design scenario.

- Q: Can steel angles be used for manufacturing safety barriers?

- Yes, steel angles can be used for manufacturing safety barriers. Steel angles are commonly used in construction projects due to their strength and durability. They are particularly suitable for safety barriers as they provide a sturdy framework that can withstand impact and provide protection. Steel angles can be easily welded or bolted together to create a solid and secure barrier. Additionally, steel angles can be galvanized or coated with anti-corrosive materials to enhance their longevity and resistance to environmental factors. Overall, steel angles are an excellent choice for manufacturing safety barriers due to their strength, durability, and versatility.

- Q: Can steel angles be painted or finished for decorative purposes?

- Indeed, steel angles have the potential to be painted or finished in order to achieve decorative purposes. These steel angles, commonly utilized in construction and industrial settings, can undergo painting or finishing procedures to enhance their visual appeal and contribute a decorative element. The act of painting steel angles serves the dual purpose of safeguarding them against corrosion and rust, while also allowing for customization to align with the aesthetic requirements of the particular project. Furthermore, alternative finishes such as powder coating, electroplating, or galvanizing can be employed to augment both the appearance and durability of these steel angles. Through the application of paint or finishing techniques, steel angles can be seamlessly integrated into a variety of architectural and design ventures, thereby serving both functional and visually enticing purposes.

- Q: Can steel angles be used in bridge construction?

- Yes, steel angles can definitely be used in bridge construction. Steel angles, also known as L-shaped structural steel, are commonly used as cross-sectional supports in bridge construction. They are particularly useful for providing stability, strength, and rigidity to bridge structures. Steel angles are versatile and can be used for various bridge components such as beams, trusses, and bracing systems. They are often welded or bolted together to form structural connections, ensuring the integrity and load-carrying capacity of the bridge. Steel angles offer several advantages in bridge construction, including their high strength-to-weight ratio, durability, and resistance to corrosion. Overall, steel angles are a reliable and widely used component in the construction of bridges.

- Q: What are the different methods of joining steel angles?

- There are several methods of joining steel angles, which are commonly used in construction and fabrication projects. These methods include welding, bolting, riveting, and adhesive bonding. 1. Welding: This is the most common and widely used method for joining steel angles. It involves melting the two angles together using heat and adding a filler material, typically in the form of a welding rod or wire, to create a strong and permanent bond. Welding provides excellent strength and integrity to the joint, and it can be done using various techniques such as arc welding, MIG welding, or TIG welding. 2. Bolting: Bolting is another common method of joining steel angles, especially when the joint needs to be versatile and easily disassembled. It involves using bolts, nuts, and washers to connect the angles together. This method provides a strong and rigid connection, and it allows for easy adjustment or removal of the angles if necessary. 3. Riveting: Riveting is a traditional method of joining steel angles that involves the use of rivets. Rivets are cylindrical metal pins that are inserted through holes drilled in the angles and then hammered or pressed to create a permanent connection. While riveting is less commonly used today due to advancements in welding and bolting techniques, it can still be a suitable method for joining steel angles in certain applications. 4. Adhesive Bonding: Adhesive bonding is a method that involves using industrial adhesives to join steel angles together. This method is particularly useful when aesthetics, weight reduction, or vibration dampening are important considerations. Adhesive bonding provides a clean and seamless joint, and it can be an effective alternative to welding or bolting in certain situations. Each method of joining steel angles has its advantages and disadvantages, and the choice of method depends on factors such as the intended use of the joint, the load-bearing requirements, the design specifications, and the available equipment and resources. It is important to carefully consider these factors and consult with experts to determine the most suitable method for a specific application.

- Q: How are steel angles tested for quality control?

- Steel angles are tested for quality control through various methods such as visual inspection, dimensional measurements, and mechanical testing. Visual inspection involves checking for surface defects, such as cracks, pits, or uneven surfaces. Dimensional measurements are conducted to ensure that the angles meet the specified size and shape requirements. Mechanical testing involves subjecting the angles to load or impact tests to assess their strength and durability. These quality control measures help ensure that steel angles adhere to industry standards and meet the required quality criteria.

- Q: What is the difference between galvanized and black steel angles?

- Galvanized and black steel angles are two types of steel angles that have distinct characteristics and uses. Galvanized steel angles are coated with a layer of zinc, which provides protection against corrosion. The process of galvanization involves immersing the steel angles in a bath of molten zinc, allowing the zinc to bond with the steel surface. This protective zinc coating increases the longevity and durability of the steel angles, making them resistant to rust and other forms of corrosion. Galvanized steel angles are commonly used in outdoor applications, such as construction projects, fencing, and marine environments where exposure to moisture and harsh weather conditions is a concern. On the other hand, black steel angles do not have any protective coating. They are simply made from raw steel, which gives them a black appearance. Black steel angles are typically used in indoor applications, such as structural support, framing, and general fabrication. Since they are not protected against corrosion, they are not suitable for outdoor use or environments with high moisture content. In summary, the main difference between galvanized and black steel angles lies in their coating and corrosion resistance. Galvanized steel angles have a zinc coating that protects them from rust and corrosion, making them suitable for outdoor applications. Black steel angles, on the other hand, lack any protective coating and are primarily used indoors for structural support and general fabrication purposes.

- Q: What are the different methods of impact testing for steel angles?

- To assess the toughness and resistance of steel angles, engineers and manufacturers have access to various impact testing methods. These include the Charpy V-notch test, the Izod test, and the drop weight test. The Charpy V-notch test is widely utilized and involves placing a notched specimen of the steel angle in a pendulum hammer. Upon release, the hammer swings down and strikes the specimen. The energy absorbed by the specimen before it fractures determines the material's impact toughness. Similarly, in the Izod test, a notched specimen is clamped vertically, and a pendulum hammer strikes it horizontally. The absorbed energy is then measured to evaluate the specimen's impact resistance. Finally, the drop weight test requires dropping a weight onto a supported specimen from a specific height. The impact energy is calculated based on the weight and drop height. The specimen's deformation and fracture behavior are analyzed to determine its impact toughness. These diverse impact testing methods provide engineers and manufacturers with vital insights into the ability of steel angles to endure sudden impacts or shock loads. By assessing the material's toughness and resistance, these tests aid in designing structures and selecting suitable materials for various applications.

- Q: How do you calculate the slenderness ratio of a steel angle?

- To calculate the slenderness ratio of a steel angle, you need to determine the length and the moment of inertia of the angle section. The slenderness ratio is a measure of how slender or slender a member is, and it helps in determining its stability and ability to resist buckling. First, measure the length of the steel angle, which is the distance between its two ends. This length should be measured in the same unit as the dimensions of the angle section. Next, calculate the moment of inertia of the steel angle section. The moment of inertia is a measure of the section's resistance to bending and is typically denoted by the symbol "I". It depends on the dimensions of the angle section and can be obtained from reference tables or calculated using mathematical formulas. Once you have the length and moment of inertia of the steel angle, you can calculate the slenderness ratio using the formula: Slenderness ratio = (Length of angle) / (√(Moment of inertia)) Make sure the length and moment of inertia are expressed in the same unit before performing the calculation. The resulting slenderness ratio will be a dimensionless value. It is important to note that the slenderness ratio is used to determine the appropriate design criteria and allowable loads for the steel angle. Different design codes or standards may have specific limits or guidelines for the maximum slenderness ratio that can be used safely in different applications. Therefore, it is crucial to consult the relevant design codes or seek professional engineering advice to ensure the correct and safe use of the steel angle.

Send your message to us

Angle Steel, Hot Rolled Steel Angle Bars, Unequal Angle Steel

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 30000 m.t./month

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

Similar products

Hot products

Hot Searches

Related keywords