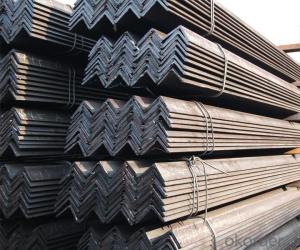

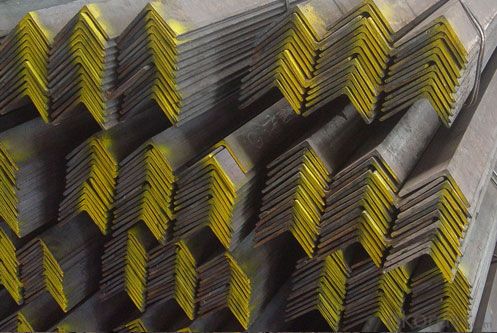

Unequal Angles Hot Rolled, Standard Unequal Angle Steel

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 30 m.t.

- Supply Capability:

- 40000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Description:

OKorder is offering Unequal Angles Hot Rolled, Standard Unequal Angle Steel at great prices with worldwide shipping. Our supplier is a world-class manufacturer of steel, with our products utilized the world over. OKorder annually supplies products to European, North American and Asian markets. We provide quotations within 24 hours of receiving an inquiry and guarantee competitive prices.

Product Applications:

Unequal Angles Hot Rolled, Standard Unequal Angle Steel are ideal for structural applications and are widely used in the construction of buildings and bridges, and the manufacturing, petrochemical, and transportation industries.

Product Advantages:

OKorder's Unequal Angles Hot Rolled, Standard Unequal Angle Steel are durable, strong, and resist corrosion.

Main Product Features:

· Premium quality

· Prompt delivery & seaworthy packing (30 days after receiving deposit)

· Corrosion resistance

· Can be recycled and reused

· Mill test certification

· Professional Service

· Competitive pricing

Product Specifications:

Hot Rolled Steel Unequal Angles

1. Shape:Unequal

2. Standard:ASTM,BS,DIN,GB,JIS

3.Grade:Q195,Q235,Q345,SS400,A36,ST37

May we help you to optimize your products sourcing? | |

1. Strategic location: Our factory is located in the famous steel town of Shengfang. | |

2. Industrial product expertise | |

3. Product reliability, competitive price, and on-time delivery | |

4. Unparalleled service and reliability | |

5. Business philosophy: Credit First, Be Honesty, Mutual Benefit and Customer Supremacy. | |

Detail information: | |

Type | Equal & Unequal |

Thickness Tolerance | +/- 8% |

Packing | export standard packing(bundles, seaworthy package, shipped in container) |

Delivery Port | Tianjin, China |

Lead Time | within 30days after received the original L/C or deposit |

MOQ | 10 Tons per size |

Certificate | SGS Certificate if needed; the cost of inspection for buyer. |

Usage | Construction, communications steel tower, civil or agricultural machine making |

Production Capacity | 5,000MT per month |

Main Market | Europe, America, Africa, Southeast |

Welcome every old and new clients to come to negotiate and telecommunicate with us | |

FAQ:

Q1: Why buy Materials & Equipment from OKorder.com?

A1: All products offered byOKorder.com are carefully selected from China's most reliable manufacturing enterprises. Through its ISO certifications, OKorder.com adheres to the highest standards and a commitment to supply chain safety and customer satisfaction.

Q2: How do we guarantee the quality of our products?

A2: We have established an advanced quality management system which conducts strict quality tests at every step, from raw materials to the final product. At the same time, we provide extensive follow-up service assurances as required.

Q3: How soon can we receive the product after purchase?

A3: Within three days of placing an order, we will begin production. The specific shipping date is dependent upon international and government factors, but is typically 7 to 10 workdays.

Q4: What makes stainless steel stainless?

A4: Stainless steel must contain at least 10.5 % chromium. It is this element that reacts with the oxygen in the air to form a complex chrome-oxide surface layer that is invisible but strong enough to prevent further oxygen from "staining" (rusting) the surface. Higher levels of chromium and the addition of other alloying elements such as nickel and molybdenum enhance this surface layer and improve the corrosion resistance of the stainless material.

Q5: Can stainless steel rust?

A5: Stainless does not "rust" as you think of regular steel rusting with a red oxide on the surface that flakes off. If you see red rust it is probably due to some iron particles that have contaminated the surface of the stainless steel and it is these iron particles that are rusting. Look at the source of the rusting and see if you can remove it from the surface.

Images:

- Q: What are the welding techniques used for steel angles?

- Some common welding techniques used for steel angles include shielded metal arc welding (SMAW), gas metal arc welding (GMAW), and flux-cored arc welding (FCAW). These techniques are effective in joining steel angles due to their ability to provide strong and durable welds.

- Q: How do you connect steel angles together?

- Steel angles can be connected together by various methods such as welding, bolting, or using steel angle brackets.

- Q: How do steel angles perform in terms of vibration resistance?

- Steel angles generally have good vibration resistance due to their strong and rigid structure. The shape of a steel angle, with its L-shaped cross-section, provides additional strength and stability, making it highly resistant to vibrations. When used in construction or engineering applications, steel angles can effectively absorb and dampen vibrations, minimizing the risk of structural damage or failure. The stiffness and high tensile strength of steel angles allow them to withstand dynamic loads and vibrations caused by various factors such as wind, earthquakes, or machinery operations. They can effectively distribute and dissipate vibrational forces throughout their structure, preventing excessive movement or oscillation. This is particularly important in applications where stability and durability are crucial, such as in the construction of bridges, buildings, or industrial equipment. Additionally, steel angles can be designed and manufactured to meet specific vibration resistance requirements. By selecting appropriate steel grades and dimensions, engineers can optimize the performance of steel angles in terms of vibration resistance. They can also incorporate additional features like stiffeners or reinforcements to further enhance the vibration resistance of steel angle structures. Overall, steel angles have proven to be reliable and efficient in withstanding vibrations, making them a popular choice in various industries and applications where structural integrity is of utmost importance.

- Q: Are steel angles resistant to wind loads?

- Yes, steel angles are generally resistant to wind loads due to their high strength and structural integrity.

- Q: What is the maximum length for a steel angle?

- The maximum length of a steel angle can differ based on the angle's specific type and size, as well as the steel supplier's manufacturing capabilities. Typically, steel angles are offered in standard lengths spanning from 20 to 40 feet. However, longer lengths could be attainable via custom orders or specialized production methods. To ascertain the readily available or obtainable maximum length for a particular steel angle, it is advisable to seek guidance from a steel supplier or manufacturer.

- Q: How do steel angles provide structural support?

- Steel angles provide structural support by distributing and transferring loads and forces in various structures. They are commonly used as braces or brackets to reinforce and stabilize beams, columns, and other members. The L-shaped design of steel angles allows them to resist bending and provide strength and rigidity to the structure. They can be bolted or welded to the main structural components, thereby increasing their load-carrying capacity and overall stability.

- Q: What is the keel of the aluminum single board suspended or the welded frame of angle steel?

- Light steel keel, is a kind of new building materials, with the rapid development of China's modernization construction, light steel keel is widely used in hotels, airport lounges, car transport station, station, amusement parks, shopping malls, factories, office buildings, building renovation, interior decoration, ceiling set of old buildings and other places. Light steel (paint) keel ceiling has light weight, high strength, adapt to waterproof, shock, dust, sound insulation, sound absorption, constant temperature and other effects, but also has the advantages of short construction period, simple construction and so on.

- Q: Are steel angles suitable for corrosive environments?

- Steel angles can be suitable for corrosive environments, depending on the specific conditions and the type of steel used. Stainless steel angles, for example, are highly resistant to corrosion due to the high levels of chromium and nickel in their composition. They are often used in environments where there is exposure to moisture, chemicals, or saltwater, such as marine applications or industrial settings. However, carbon steel angles may not be as suitable for corrosive environments as they are more prone to rust and corrosion. In such cases, additional protective measures such as coatings or galvanization may be necessary to enhance their resistance to corrosion. It is important to consider the specific corrosive elements present in the environment, the level of exposure, and the required longevity of the steel angles. Consulting with a corrosion specialist or an engineer experienced in materials selection can help determine the most suitable steel angles for corrosive environments.

- Q: How do steel angles compare to other structural materials like wood or aluminum?

- Steel angles have distinct advantages over other structural materials like wood or aluminum. Firstly, steel angles are much stronger and more durable than wood, making them suitable for high-load bearing applications. Additionally, steel angles have excellent fire resistance compared to wood, making them a safer choice in construction. When compared to aluminum, steel angles offer superior strength and rigidity, making them more suitable for heavy-duty applications. Moreover, steel angles are more cost-effective and have a longer lifespan than aluminum, making them a preferred choice for many construction projects.

- Q: What are the different types of steel coatings available for angles?

- There are several different types of steel coatings available for angles, each with its own unique characteristics and benefits. Some of the most common types include: 1. Galvanized coating: This is one of the most popular and widely used types of steel coating for angles. Galvanization involves applying a layer of zinc to the surface of the steel, providing excellent corrosion resistance. Galvanized angles are commonly used in outdoor applications or in environments where moisture and humidity are present. 2. Powder coating: Powder coating is a type of dry finishing process that involves applying a fine powder to the surface of the steel angles. The powder is electrostatically charged and adheres to the metal, creating a smooth, durable, and attractive finish. Powder coating provides excellent resistance to scratches, chipping, and fading, making it a popular choice for decorative or architectural applications. 3. Epoxy coating: Epoxy coatings are a type of thermosetting polymer that is applied to the surface of the steel angles. These coatings provide exceptional resistance to chemicals, corrosion, and abrasion, making them suitable for harsh and demanding environments. Epoxy-coated angles are commonly used in industrial settings, such as chemical plants or wastewater treatment facilities. 4. Paint coating: Paint coatings are a traditional and cost-effective option for steel angles. They are typically applied as a liquid and can be customized in terms of color and finish. While paint coatings provide some level of protection against corrosion, they may not be as durable or long-lasting as other types of coatings. However, they can still be suitable for indoor or low-corrosion applications. 5. Organic coating: Organic coatings, such as polyurethane or polyester, are often used to provide a decorative or protective layer to steel angles. These coatings offer excellent resistance to UV radiation, weathering, and fading, making them suitable for outdoor applications. Organic-coated angles can be found in architectural, construction, or infrastructure projects. It's important to consider the specific requirements of your application when choosing a steel coating for angles. Factors such as environmental conditions, aesthetic preferences, and durability needs should all be taken into account to ensure the proper selection of the coating that best suits your project.

Send your message to us

Unequal Angles Hot Rolled, Standard Unequal Angle Steel

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 30 m.t.

- Supply Capability:

- 40000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords