Aluminum Zinc Rolled Coil for Construction

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 500 m.t.

- Supply Capability:

- 30000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

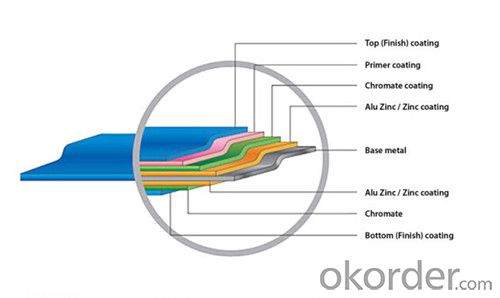

Structure of Aluminum Zinc Rolled Coil

Description of Aluminum Zinc Rolled Coil

Standard | ASTM A653, JIS G3302,GB/T3830-2006 |

Grade | DX51D,SGCC,SPCC,SGHC |

Thickness | 0.18mm--1.2mm |

Width | 400-1250mm(usual size:914mm,1000mm,1200mm,1219mm,1250mm,) |

Base metal | Galvanized steel coils |

Zinc coating | 40-80gsm |

Coil ID | 508mm,610mm |

Coating thickness | Top:17-25um back:5-8um |

Color options | Ral number or as per your request |

Packing | 3 Layer Standard seaworthy export packing: Inside is kraft paper ,water plastic film in the middle Outside GI steel sheet to be covered by steel strips with lock inner coil sleeve. |

Main Feature of Aluminum Zinc Rolled Coil

Corrosion resistance

Weather resistance

Long working life

Good formability

Applications of Aluminum Zinc Rolled Coil

1. Construction and building: roofing; ventilating duct; handrail; partition panel;etc.

2. Electric appliance: refrigerator; washing machine; refrigerator; DVD;etc.

3.Transportation: oil tank; road sign; etc.

4.Agriculture:barn; etc.

5.Others:vending machine; game machine; etc.

Aluminum zinc rolled coil images

FAQ of Aluminum Zinc Rolled Coil

We have organized several common questions for our clients,may help you sincerely:

1. What is the minimum order quantity ?

Our MOQ is 50mt for each size. And we will consider to give more discount if you make big order like 1000 tons and more. Further more, the more appropriate payment term your offer the better price we can provide.

2. How long can we receive the product after purchase?

Usually within thirty working days after receiving buyer’s advance payment or LC. We will arrange the factory manufacturing as soon as possible. The cargo readiness usually takes 15-25 days, but the shipment will depend on the vessel situation.

3. How to guarantee the quality of the products?

We have established the international advanced quality management system,every link from raw material to final product we have strict quality test;We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

- Q: What is the maximum width of a steel coil?

- The maximum width of a steel coil can vary depending on the manufacturing process and the specific requirements of the industry. However, in general, steel coils can have a maximum width of around 2,200 millimeters (86.6 inches).

- Q: How are steel coils inspected for mechanical properties?

- Steel coils are inspected for mechanical properties through a series of tests and measurements. These include hardness testing, tensile testing, and elongation testing to determine the steel's strength, ductility, and overall quality. Additionally, non-destructive testing methods like ultrasonic testing and magnetic particle inspection are used to detect any potential defects or flaws in the coils. Overall, a combination of these inspection techniques ensures that steel coils meet the required mechanical properties for their intended applications.

- Q: Can steel coils be used in the manufacturing of machinery and equipment?

- Machinery and equipment manufacturing can indeed utilize steel coils effectively. These coils possess remarkable versatility and contribute strength, durability, and stability to various industrial applications. They can be manipulated to assume various shapes, receive cuts, and undergo formation to generate diverse parts and components that are indispensable to the manufacturing process of machinery and equipment. Gears, shafts, frames, brackets, and other structural elements are commonly produced using steel coils. Moreover, these coils can undergo further processing to fashion specialized components like springs or fasteners. By incorporating steel coils into machinery and equipment manufacturing, the end products are guaranteed to possess exceptional quality, capable of enduring heavy loads, and boasting an extended lifespan.

- Q: Eutectoid Steel

- Eutectic steel is used to produce pearlite, bainite, spheroidite and martensite steels. Those steels vary in strength, hardness and ductility. One uses martensite steel for example in razor blade manufacturing. Of course there is no end to the various uses of these steels.

- Q: I'm looking for the weight of different types of steel and haven't found anything helpful!!thank you

- Category Material Density Metal Steel, tool 7.715 Metal Wrought Iron 7.75 Metal Carbon Tool Steel 7.82 Metal Steel, cold-drawn 7.83 Metal Carbon Steel 7.84 Metal Steel, C1020, HR 7.85 Metal Pure Iron 7.86 Metal Soft Steel (0.06% C) 7.87 Metal Stainless Steel, 304 8.03 Metal Stainless 18Cr-8Ni 8.03 I looked up specific gravity mild steel. This might get you pointed in the right direction.

- Q: How are steel coils inspected for impact resistance?

- To ensure the durability and ability of steel coils to withstand external forces, they are commonly inspected for impact resistance using various methods. One such method is the drop test, where a steel coil is dropped from a specified height onto a hard surface, simulating the impact it may experience during transportation or handling. During the drop test, the coil is visually examined for visible signs of damage, such as dents, cracks, or deformations. Additionally, other examinations like ultrasonic testing or magnetic particle inspection may be conducted to detect hidden internal defects that could compromise its impact resistance. Another method employed to inspect steel coils for impact resistance is the pendulum test. This involves swinging a pendulum with a known weight and height to strike the surface of the coil. The amount of energy absorbed by the coil during the impact is measured and used to assess its resistance to impact. Furthermore, laboratory tests like Charpy impact testing may be conducted on steel coils to determine their resistance to sudden impacts. This test involves striking a notched sample of the coil with a pendulum hammer, measuring the energy absorbed by the sample, and evaluating its impact strength. Overall, a combination of drop tests, visual inspections, non-destructive testing methods, pendulum tests, and laboratory tests are employed to inspect steel coils for impact resistance. These inspections ensure that the coils meet the required standards and can endure the potential challenges they may face during transportation, storage, and usage.

- Q: does he use a nylon guitar or steel?

- He's using a nylon guitar. The trick to know whether it is nylon or steel is by looking at the headstock. steel ones use the ones you see from a regular electric guitar. the nylon ones has two major holes on them I don't know why but that's based on what i have seen. One more thing is its bridge. the nylon ones do not use pin-like stoppers to prevent the strings from falling off unlike the steel-stringed guitars that use them.

- Q: Is this a strong, durable piece of steel that can take abuse? I'm thinking about using it on a small project.

- Your terms of strong and durable are not specific enough to know what you really need. Are you describing an application where you are using this as a spring or a structural support? Here is description home depot provides: Simpson Strong-Tie straps and plates join and reinforce joints with simple, versatile solutions for a wide range of connections. Available in many lengths, widths and thicknesses, YOur temcan be used on the wide or narrow face of lumber for light repairs or heavy-duty projects. Many straps are designed to be used back-to-back on a piece of lumber without fastener interference. A versatile, medium-duty strap for a variety of connections and splices Designed for use on the edge of 2x members, with a nailing pattern that reduces potential for splitting Install where plates or soles are cut, at wall intersections and as ridge ties 12 in. Length Made from 18-Gauge steel Stainless Steel offers extra corrosion resistance for exterior and treated-wood applications Install with 10d common nails If your application sounds like what they describe you should be fine. If it doesn't you may have trouble. As far as tempering your stainless I doubt you will be successful. If you take a magnet and it is not attracted to this strap, the strap is 304 SS. 304SS only gains strength through work hardening (making it thinner by rolling) Heat treating doesn't affect it.

- Q: Is there any way to melt steel without the intense heat of a blast furnace?

- So unless you have a large anount of steel in a large oven and meticulous process control including chemical sampling, your product will end up looking like a piece of iron age metal. But if all you want is to see steel melt, any old blowtorch will do the job. The metal at the end of the process will be useless for pretty much any technical purposes, though.

- Q: How did the growth of the steel industry influence the development of other industries?

- At least three ways: 1. Steel as a material that other industries could use to do things that couldn't be done before (for example, construction (skyscrapers, long bridges, etc.)) or could now be done at much lower cost and hence increased the size of the industry (automobiles, bearings, etc.)

Send your message to us

Aluminum Zinc Rolled Coil for Construction

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 500 m.t.

- Supply Capability:

- 30000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords