Prepainted Aluminum Zinc Rolled Coil for Roof Construction

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 30000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Structure of Aluminum Zinc Rolled Coil

Description of Aluminum Zinc Rolled Coil

Aluminum zinc coils is a kind of coated steel coil/sheet. With the cold rolled steel of different strength and thickness as substrate, it is produced through applying Al-Zn coat on both faces by hot dip process. In its coating, Al accounts for about 55%, Si 1.6%, while the remaining is Zn. Aluminum zinc coils enjoys both the physical protective feature and durability of Al and the electrochemical protective property of Zn. And its surface has bright silver color and regular embossed-like figure, which are highly decorative.

Main Feature of Aluminum Zinc Rolled Coil for Construction Roof

1.Corrosion resistance: It mainly depends on the aluminum protection. When the zinc being worn, the aluminum will form a dense layer of aluminum oxide, resist corrosion material to prevent further corrosion inside.

2. Heat resistance: Aluminum zinc alloy steel sheet has excellent heat resistance, can withstand high temperatures over 300 centigrade, and is similar with aluminized steel high temperature oxidation resistance. It often used in chimney pipes, ovens, fluorescent lighting device and the device cover.

3. Heat reflective: Galvanized steel plate heat-reflective high rate is twice as galvanized steel, often used to make insulation materials.

4. Economy: Because density of 55% AL-Zn is smaller than the density of Zn, so in the same weight and thickness of Galvanized zinc layer, aluminum-zinc steel plate is larger area more than 3% of galvanized steel sheet.

Applications of Aluminum Zinc Rolled Coil for Construction Roof

1. Construction and building: roofing; ventilating duct; handrail; partition panel;etc.

2. Electric appliance: refrigerator; washing machine; refrigerator; DVD;etc.

3.Transportation: oil tank; road sign; etc.

4.Agriculture:barn; etc.

5.Others:vending machine; game machine; etc.

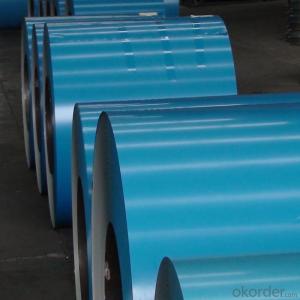

Prepainted Aluminum Zinc Rolled Coil for Construction Images

Specifications of Prepainted Aluminum Zinc Rolled Coil for Construction

Surface Treatment | Feature |

Chemical Treatment | minimize the chance of humid-storage staining forms a dark gray surface discoloration on the surface |

retain the bright metallic luster for a long period | |

Oil | minimize the tendency for humid-storage stain |

Chemical Treatment and Oil | The chemical treatment provides very good protection against humid-storage staining, while the oil provides lubricity for operations. |

Dry | must be transported and stored with special precautions to preserve low-humidity conditions. |

Anti-finger print | minimize the chance of humid-storage staining forms a dark gray surface discoloration on the surface |

FAQ of Prepainted Aluminum Zinc Rolled Coil for Construction

We have organized several common questions for our clients,may help you sincerely:

1. What is the minimum order quantity ?

Our MOQ is 50mt for each size. And we will consider to give more discount if you make big order like 1000 tons and more. Further more, the more appropriate payment term your offer the better price we can provide.

2. How long can we receive the product after purchase?

Usually within thirty working days after receiving buyer’s advance payment or LC. We will arrange the factory manufacturing as soon as possible. The cargo readiness usually takes 15-25 days, but the shipment will depend on the vessel situation.

3. How to guarantee the quality of the products?

We have established the international advanced quality management system,every link from raw material to final product we have strict quality test;We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

- Q: What is the maximum thickness of steel coils?

- The maximum thickness of steel coils can vary depending on various factors such as the type of steel, manufacturing process, and industry requirements. However, in general, steel coils can range from a few millimeters to several inches in thickness.

- Q: How are steel coils used in the production of aerospace parts?

- Steel coils are widely used in the production of aerospace parts due to their strength, durability, and versatility. These coils are typically made from high-quality carbon steel and are formed into a coil shape for easy transport and storage. In the aerospace industry, steel coils are primarily used in the manufacturing of various components such as structural parts, engine parts, landing gear, and fasteners. One of the main applications of steel coils is in the fabrication of aircraft frames and fuselage structures. These coils are often cut, shaped, and welded to create the necessary structural components that provide strength and stability to the aircraft. Another important use of steel coils in aerospace production is in the manufacturing of engine parts. Steel coils are processed and formed into complex shapes to create components such as turbine blades, shafts, and casings. These components need to withstand high temperatures, pressure, and stress, and steel coils offer the necessary strength and heat resistance required for such demanding applications. Steel coils are also utilized in the production of landing gear, which is responsible for supporting the aircraft during takeoff, landing, and ground operations. The coils are processed and formed into various parts of the landing gear system, including struts, beams, and brackets. These parts undergo rigorous testing and need to possess excellent strength, toughness, and fatigue resistance, all of which are provided by steel coils. Furthermore, steel coils are commonly used for manufacturing fasteners in aerospace applications. Fasteners such as bolts, screws, and rivets play a crucial role in joining different components together, ensuring structural integrity and safety. Steel coils are processed and formed into the desired fastener shapes, providing the necessary strength and reliability for these critical connections. Overall, steel coils are essential in the production of aerospace parts due to their exceptional mechanical properties and reliability. Their versatility allows for various shaping and processing techniques, enabling the creation of complex and high-performance components. By utilizing steel coils in aerospace manufacturing, the industry can ensure the production of durable, safe, and efficient aircraft.

- Q: How do steel coil manufacturers stay updated with industry trends?

- Steel coil manufacturers utilize various methods to stay informed about industry trends: 1. Attending industry conferences and trade shows allows manufacturers to connect with other professionals, attend seminars and presentations, and learn about the latest trends and innovations in the steel coil industry. 2. Subscribing to industry publications and magazines provides manufacturers with regular updates on trends, market insights, and technological advancements in the steel coil industry. These publications often feature articles and interviews with experts, delivering valuable information to stay updated. 3. Actively participating in online forums, discussion boards, and social media groups dedicated to steel coil manufacturing helps manufacturers stay connected with the industry. These platforms allow them to engage with peers, share knowledge, ask questions, and stay updated on the latest trends. 4. Maintaining close relationships with suppliers and customers enables manufacturers to gain insights into changing market demands, new product requirements, and emerging trends. Suppliers and customers often share information about industry trends and advancements that assist manufacturers in adapting their processes accordingly. 5. Investing in continuous education and training programs for employees ensures that the workforce remains updated on the latest industry trends, technological advancements, and best practices. Prioritizing employee development equips manufacturers with the skills and knowledge necessary to stay ahead of the curve. 6. Allocating resources for research and development activities allows steel coil manufacturers to explore new materials, manufacturing techniques, and technologies. By investing in R&D, manufacturers can stay at the forefront of industry trends and develop innovative solutions that meet evolving customer demands. 7. Staying updated with government regulations, industry standards, and certifications that impact the steel coil industry is crucial. Compliance with these regulations often requires manufacturers to adopt new practices, technologies, or materials, ensuring that they remain up to date with the latest trends and requirements. By actively engaging in these activities, steel coil manufacturers can stay informed about industry trends, emerging technologies, and market demands. This enables them to adapt their processes, products, and strategies to remain competitive and meet the evolving needs of their customers.

- Q: My daughter wants a pair of steel toe cap boots for around the horses but wants them warm, so ideally fur lined etc. Does anybody know where I could purchase them as everywhere I look its only one or the other, cant get steel with fur lining. Very frustrating. I live in the uk. Many thanks.

- Steel toe boots around horses is a big no-no! horses are heavy enough to bend the steel and that could possibly cut into her foot. Even if it doesn't cut into her foot, the boot is ruined after the first time a horse does step on it. On the other hand, Mountain Horse and Ariat both make great winter riding boots.

- Q: What are the dimensions of steel coils used in the pipeline industry?

- The specific application and requirements play a significant role in the variation of dimensions for steel coils utilized in the pipeline industry. Generally, the dimensions for steel coils used in this industry fall within the range of 0.5 to 3.0 inches in thickness and 24 to 60 inches in width. The length of the coils can also vary, with standard lengths typically falling between 100 and 200 feet. These dimensions are carefully chosen to ensure the necessary strength and durability for pipeline construction and the transportation of various fluids and gases. It is crucial to acknowledge that these dimensions may differ depending on the project's specifics and the standards set by the industry.

- Q: Can steel coils be custom-made to specific requirements?

- Yes, steel coils can be custom-made to specific requirements.

- Q: Ok, so im gonna get my tragus pierced and i was wondering which is better, titanium or stainless steel. I hear like everyone uses stainless steel , but is titanium better?Thanks

- all my piercings are with stainless steel..... i never had any problems with it honestly.... cause when i get my tragus pierced the lady is going to use stainless steel... cause when i got my navel done it was with stainless steel... most people cause have stainless steel they have to have other different types

- Q: What are the different types of steel coil finishing processes?

- Enhancing the appearance and properties of steel coils involves employing various steel coil finishing processes. Among the commonly used processes are: 1. Hot-dip galvanizing: Immersing the steel coil in molten zinc forms a protective layer on its surface, enhancing corrosion resistance and providing a visually pleasing finish. 2. Cold rolling: Passing the steel coil through rollers at room temperature reduces thickness and improves surface finish. This process can yield finishes ranging from matte to highly polished. 3. Electro-galvanizing: A thin layer of zinc is electrolytically deposited onto the steel coil's surface. This method is suitable for applications requiring a thinner zinc coating and a more uniform finish. 4. Pickling and oiling: Treating the steel coil with an acid solution removes scale and impurities, resulting in a clean and smooth surface. Coating the coil with oil prevents rust during storage and transportation. 5. Powder coating: Dry powder is applied to the steel coil and cured under heat to form a durable and attractive finish. This method allows for a wide range of colors and finishes. 6. Paint coating: Similar to powder coating, liquid paint is applied to the steel coil's surface. This process offers decorative finishes and protection against corrosion and environmental factors. These examples represent only a few of the available steel coil finishing processes. The choice of method depends on specific application requirements, including desired appearance, corrosion resistance, and durability.

- Q: Can steel coils be coated with thermally insulating materials?

- Yes, steel coils can be coated with thermally insulating materials.

- Q: What are the common methods of transporting steel coils?

- There are several common methods of transporting steel coils, depending on the distance, quantity, and specific requirements of the shipment. The most commonly used methods include: 1. Flatbed trucks: This is the most basic and widely used method for short-distance transportation of steel coils. Flatbed trucks have a flat, open trailer bed that allows for easy loading and unloading of the coils. The coils are secured and strapped down to prevent movement during transit. 2. Rail transport: For longer distances, rail transport is often preferred due to its cost-effectiveness and efficiency. Coils are loaded onto specially designed railcars, known as coil cars or gondola cars, which have curved troughs or cradles to hold the coils securely in place. This method is particularly advantageous for large quantities of steel coils. 3. Ocean freight: When transporting steel coils internationally or over long distances across oceans, shipping by sea is a common method. The coils are typically loaded into specialized shipping containers, known as coil containers or coiled steel containers, which have internal cradles to prevent movement and damage during transit. These containers are then loaded onto cargo ships for transportation. 4. Barge transport: In regions with navigable waterways, barges can be used to transport steel coils. Similar to ocean freight, the coils are loaded into specially designed containers or barges with cradles to secure them during transport. Barges offer an economical and environmentally friendly option, especially for inland waterway transportation. 5. Intermodal transport: In some cases, a combination of different modes of transportation may be used for transporting steel coils. This is referred to as intermodal transport. For example, steel coils may be initially transported by truck to a rail yard, where they are then loaded onto railcars for long-distance transport. This method allows for the advantages of different modes of transportation to be combined, optimizing cost and efficiency. It is worth noting that the specific method of transporting steel coils may vary depending on factors such as coil size, weight, destination, and any specific handling requirements.

Send your message to us

Prepainted Aluminum Zinc Rolled Coil for Roof Construction

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 30000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords