Aluminum Zinc Rolled Coil for Steel Roof Build

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m.t.

- Supply Capability:

- 30000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Aluminum Zinc Rolled Coil for Steel Roof Building

Aluminum Zinc Rolled Coil for Steel Roof Building

Aluminum zinc coils is a kind of coated steel coil/sheet. With the cold rolled steel of different strength and thickness as substrate, it is produced through applying Al-Zn coat on both faces by hot dip process. In its coating, Al accounts for about 55%, Si 1.6%, while the remaining is Zn. Aluminum zinc coils enjoys both the physical protective feature and durability of Al and the electrochemical protective property of Zn. And its surface has bright silver color and regular embossed-like figure, which are highly decorative.

Aluminum Zinc Rolled Coil for Steel Roof Building

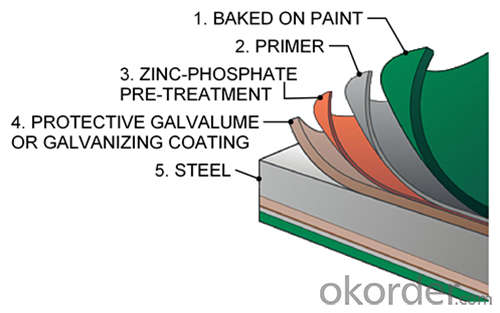

1) Aluminum zinc coils is formable, weldable and paintable.

2) Aluminum zinc coils has superior long term corrosion resistance in the most atmospheric conditions. This is achieved through the combination of the sacrificial protection of the zinc and the barrier protection of the aluminum.

3) Aluminum zinc coils coating out-perform galvanized coating from 2-6 times than hot dip galvanized steel.

Aluminum Zinc Rolled Coil for Steel Roof Building

1) Construction: Roofing, cladding, structural sections, composite panels, etc.

2) Electric appliance: Washing machine, refrigerators, toaster, microwave, etc.

3) Miscellaneous: Air duct, lighting, computer casing, etc.

Aluminum Zinc Rolled Coil for Steel Roof Building

Aluminum Zinc Rolled Coil for Steel Roof Building

We have organized several common questions for our clients,may help you sincerely:

1. What is the minimum order quantity ?

Our MOQ is 50mt for each size. And we will consider to give more discount if you make big order like 1000 tons and more. Further more, the more appropriate payment term your offer the better price we can provide.

2. How long can we receive the product after purchase?

Usually within thirty working days after receiving buyer’s advance payment or LC. We will arrange the factory manufacturing as soon as possible. The cargo readiness usually takes 15-25 days, but the shipment will depend on the vessel situation.

3. How to guarantee the quality of the products?

We have established the international advanced quality management system,every link from raw material to final product we have strict quality test;We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

- Q: What are the common coil surface finish standards?

- Some common coil surface finish standards include mill finish, brushed finish, polished finish, and coated finish.

- Q: Hi All,I was wanting to know,on the quality bikes such as Trek,Giant etc is the aluminum frames as strong as the steel frame bikes? I have heard conflicting reports on this,so thought I would ask here for more input.Thanks!

- Dustin You are close, but not quite right. Steel is a great frame material, It can be heavier than its aluminum counter part, But, steel often provides a much nicer ride. Aluminum tends to be a very stiff and rigid ride that many do not like. I have had frames made of all materials. I can say that I have never met a frame material that I did not like. Check the weight of the frames you are looking at. If there is more than two pound (or so) difference then the aluminum frame would be my choice. Soccerref

- Q: and also what makes different hardness of stainless steel?

- a little clarification. steel doesn't become stainless. There are many different types of steel, which is an alloy of iron and other element. The other elements determine things like hardness, corrosion resistance, etc. One element is chromium, which when added in the correct proportions, forms stainless steel. PS, there are many many different stainless steels, with different proportions.

- Q: i got a strip of steel from lowes how to sharpen it its not that thick its kinda slim but its heavyish its around 4'2 feet tall i cant get a whetstone or anything elsei have a brick , sand paper , and a hammer and some charcoal i was heating it up and trying to pound a edge into italso how to cut the steel to make a pointy curved tip any help appreciated and please tell me easy methodsplus its not sharp at all

- Bench grinder, Dremel Hand Grinder

- Q: How are steel coils protected against corrosion?

- Steel coils are protected against corrosion through various methods such as applying protective coatings like zinc, aluminum, or polymer, or using a process called galvanization where the coils are coated with a layer of zinc. Additionally, storing the coils in a controlled environment with low humidity and proper ventilation also helps prevent corrosion.

- Q: What is the maximum weight capacity for a steel coil lifting device?

- The maximum weight capacity for a steel coil lifting device depends on various factors such as the design, size, and specifications of the specific lifting device. It is crucial to refer to the manufacturer's guidelines or consult with a qualified engineer to determine the exact weight capacity for a particular steel coil lifting device.

- Q: What are the different types of steel coil slitting machines?

- There are several different types of steel coil slitting machines, including manual slitters, semi-automatic slitters, and fully automatic slitters. Manual slitters require manual adjustment and operation, while semi-automatic slitters have some automated features but still require some manual intervention. Fully automatic slitters are the most advanced type, with fully automated controls and high-speed operation.

- Q: What are the different methods of blanking steel coils?

- There are multiple techniques utilized for blanking steel coils, including: 1. Shearing: To achieve the desired size and shape, shearing involves cutting the steel coil using a shear or a set of shears. This method is commonly used as it is fast and cost-effective, particularly suitable for thin to medium-thickness steel coils. 2. Laser cutting: Employing a high-powered laser beam, laser cutting is a precise and efficient method for cutting through steel coils. It is ideal for complex shapes and thick steel coils, providing clean and accurate cuts. Consequently, it is favored for high-quality blanking. 3. Waterjet cutting: A versatile method, waterjet cutting employs a high-pressure stream of water mixed with an abrasive material to cut through steel coils. It generates no heat and can cut through various materials, including steel. It is particularly suitable for cutting thick steel coils and intricate shapes and designs. 4. Stamping: This method involves pressing a die into the steel coil to cut out the desired shape. It is commonly used for high-volume production as it can rapidly cut multiple pieces simultaneously. Stamping is suitable for cutting simple shapes and is often combined with other processes, such as shearing or laser cutting, for more complex shapes. 5. Plasma cutting: Plasma cutting utilizes a high-velocity jet of ionized gas to cut through the steel coil. It is suitable for cutting thick steel coils and can handle a wide range of materials. Known for its speed and versatility, plasma cutting is a popular method for blanking steel coils. These methods of blanking steel coils offer various benefits depending on project requirements, such as speed, precision, complexity of shapes, and material thickness. The selection of the method relies on factors like cost, production volume, desired quality, and turnaround time.

- Q: What are the common coil coating materials?

- The common coil coating materials include polyester, polyvinylidene fluoride (PVDF), polyurethane, epoxy, and acrylic.

- Q: What are the different methods of edge trimming for steel coils?

- There are several methods of edge trimming for steel coils, depending on the specific requirements and application. Some of the common methods include: 1. Slitting: This is one of the most common methods used to trim the edges of steel coils. It involves passing the coil through a set of circular knives that cut the edges into narrower strips. Slitting can be done in-line during the manufacturing process or as a separate operation. 2. Shearing: Shearing is another popular method used for edge trimming. It involves using a set of blades to cut the edges of the coil in a straight line. Shearing is often used when precise and clean cuts are required, and it can be done manually or with the help of automated machinery. 3. Laser cutting: Laser cutting is a more advanced method that uses a high-powered laser to trim the edges of steel coils. This method provides precise and smooth cuts, and it is often used when high accuracy and quality are essential. Laser cutting can be incorporated into the production line or performed as a standalone process. 4. Grinding: Grinding is a method that involves using abrasive wheels or belts to remove material from the edges of steel coils. It is commonly used to remove burrs, rough edges, or surface imperfections. Grinding can be done manually or with the help of automated machines, depending on the scale and complexity of the trimming process. 5. Waterjet cutting: Waterjet cutting is a method that utilizes a high-pressure jet of water mixed with abrasive particles to trim the edges of steel coils. This method is known for its versatility and ability to cut through a wide range of materials and thicknesses. Waterjet cutting is typically used when complex shapes or intricate designs need to be achieved. Overall, the choice of edge trimming method for steel coils depends on factors such as the desired accuracy, speed, complexity of the edges, and the specific requirements of the application. Different methods offer varying levels of precision, efficiency, and cost-effectiveness, allowing manufacturers to select the most suitable technique for their specific needs.

Send your message to us

Aluminum Zinc Rolled Coil for Steel Roof Build

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m.t.

- Supply Capability:

- 30000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords