SPCC Cr Coil/Cold Rolled Steel Coil for Building

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 m.t.

- Supply Capability:

- 50000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

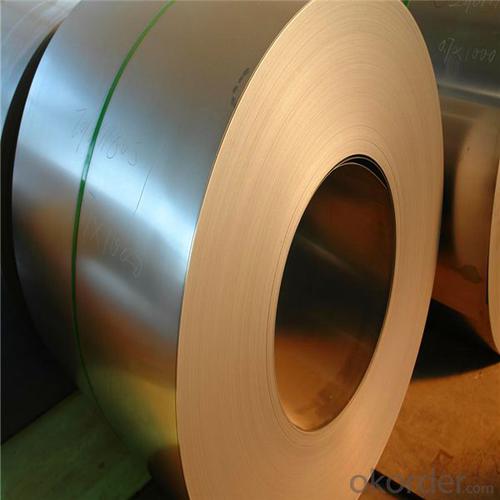

SPCC CR Coil Cold Rolled Steel Coil for building

1.Cold Rolled Steel Coil

1.Thickness:0.18-1.8mm

2.Width:700-1300mm

3.Length:as your need

4.Inner Diameter: 508mm

5.Weight of Steel Coil: 3-15MT

6.Heat Treatment: Annealed

7.Surface Quality: FB&FC

8.Surface Status: SB & SD

9.Surface Treatment: Oiling,unoil,dry,chromate passivated, non-chromate passivated

10.Standard:AISI, ASTM, BS, DIN, GB, JIS

11.Grade;SPCC/SPCD/SPCE/ST12-15/DC01-06.

12.Delivery time:15-20days after receipting the advance payment.

13.Package: Standard export packing or as your requested.

14.Technique: Cold rolled.

15.Application:Widely used in ships, automobiles, bridges, buildings, machinery, etc

16.Price terms: FOB CIF CFR

17.Payment : T/T or L/C at sight

18.Samples are available

2.Product Image

3.Packing and Delivery

Delivery time:15-20days after receipting the advance payment.

Package: Standard export packing or as your requested.

Technique:Surface Treatmentunoil,dry,chromate passivated, non-chromate passivated

Application:Widely used in ships, automobiles, bridges, buildings, machinery, etc

- Q: What are the main characteristics of galvanized steel coils?

- The main characteristics of galvanized steel coils include their high corrosion resistance, durability, and ability to withstand extreme weather conditions. They are also known for their excellent formability, making them suitable for various applications in construction, automotive, and manufacturing industries. Additionally, galvanized steel coils have a smooth and shiny appearance due to the zinc coating, which provides aesthetic appeal along with enhanced protection against rust and other damages.

- Q: Consider a steel rod of diameter 4.5 mm and length 3.3 m. If a compressive force of 4900 N is applied to each end, what is the change in the length of the rod?

- You need to calculate the stress on the rod and compare this with the mechanical properties of the steel. It would help if you were given more info. You will need to know something about the steel such as the yeild stress and E, the modulus of elasticity. The value of E is about the same for a wide range of steels. So long as the applied stress is below the yield stress, the strain is all elastic and is calculated from E. The real answer is that you can not answer this question since you do not know what the temperature is. Given the applied load, the change in length will be much different at room temperature than at 1500C.

- Q: What are the challenges in the production of steel coils?

- The production process of steel coils encounters several obstacles. Firstly, ensuring consistent quality throughout the process is a major challenge. It is necessary for steel coils to possess uniform thickness, width, and flatness. However, achieving this consistently can prove to be difficult due to variations in raw materials, equipment, and operating conditions. Another hurdle involves effectively managing the intense temperatures involved in the production process. Steel coils are formed by heating steel slabs or billets to extremely high temperatures and subsequently rolling them into coils. Maintaining the necessary temperatures and ensuring proper cooling can be a complex task, as any deviations can result in inconsistencies in the final product. Furthermore, the production of steel coils demands a significant amount of energy. The steel industry ranks among the largest energy consumers worldwide. The constant challenge lies in reducing energy consumption while maintaining production efficiency. To tackle this challenge, the implementation of energy-efficient technologies and process optimization is imperative. Moreover, the production of steel coils generates a substantial amount of waste and emissions. Steel manufacturing involves various chemical reactions that release pollutants such as carbon dioxide, sulfur dioxide, and particulate matter. Meeting environmental regulations and minimizing these emissions are significant challenges for the industry. Additionally, the production of steel coils often involves large quantities, necessitating efficient logistics and transportation systems. Ensuring timely delivery and minimizing damage during transportation can be challenging due to the weight and size of the coils. Lastly, the steel industry confronts market challenges, including fluctuating prices of raw materials, competition from alternative materials, and global economic conditions. Adapting to market demands and maintaining competitiveness are vital for the sustainable production of steel coils. Overall, the challenges in steel coil production encompass maintaining consistent quality, managing high temperatures, reducing energy consumption and emissions, optimizing logistics and transportation, and adapting to market dynamics. Addressing these challenges requires continuous innovation, technological advancements, and a focus on sustainability.

- Q: My daughter wants a pair of steel toe cap boots for around the horses but wants them warm, so ideally fur lined etc. Does anybody know where I could purchase them as everywhere I look its only one or the other, cant get steel with fur lining. Very frustrating. I live in the uk. Many thanks.

- The steel toe cap wishes to be equipped for the duration of manufacture for the boots to arrive the desired standards. It could be nice if you looked at one of the PPE sites and see if you will see a pair that you may dye or paint.

- Q: How are steel coils processed for pickling or oiling?

- Steel coils are processed for pickling or oiling by first being cleaned and then passed through a series of chemical baths or mechanical processes to remove any impurities or scale on the surface. This is followed by rinsing and drying the coils, after which they can either be pickled in acid to remove oxides or coated with oil to prevent corrosion.

- Q: What is the weight of a typical steel coil?

- The weight of a typical steel coil can vary significantly depending on its size, thickness, and type of steel used. However, a typical steel coil can range anywhere from a few hundred kilograms to several tonnes in weight.

- Q: Can steel coils be embossed?

- Yes, steel coils can be embossed. Embossing is a process that involves creating raised or sunken designs on a material, and it can be applied to steel coils to add texture or decorative patterns.

- Q: How are steel coils processed for specific applications?

- Steel coils are processed for specific applications through a series of carefully planned steps. The process begins with the selection of the appropriate grade and thickness of steel, which is determined based on the requirements of the end application. Once the steel coils are received, they undergo a series of processing steps to transform them into the desired product. The first step in processing steel coils is known as uncoiling, where the coil is unwound and straightened. This ensures that the coil is flat and ready for further processing. The uncoiled steel is then cleaned to remove any dirt, oil, or rust that may be present on the surface. This is typically done through a process called pickling, which involves immersing the steel in a bath of acid to remove any impurities. After cleaning, the steel undergoes various shaping processes depending on the desired application. This can include processes such as slitting, where the coil is cut into narrower strips, or shearing, where it is cut into specific lengths. These shaping processes are often performed using specialized machinery that can handle the high strength and thickness of steel. Once the steel has been shaped, it may undergo additional processes to enhance its properties. For example, it may be heat treated to increase its strength or hardness, or it may undergo a coating process to improve its corrosion resistance. Coating processes can include techniques such as galvanizing, where the steel is coated with a layer of zinc, or painting, where it is coated with a layer of paint. Finally, the processed steel coils are inspected for quality and undergo any necessary finishing processes. This can include processes such as trimming the edges to remove any irregularities, or applying protective coatings to prevent damage during transportation or storage. Overall, the processing of steel coils for specific applications is a complex and carefully controlled process. It involves a combination of shaping, cleaning, coating, and finishing processes to ensure that the steel meets the required specifications and is ready for use in various industries such as automotive, construction, and manufacturing.

- Q: How are steel coils used in the production of furniture components?

- Steel coils are commonly used in the production of furniture components as they provide a strong and durable material for construction. These coils can be shaped, cut, and formed into various components such as frames, supports, and brackets, adding strength and stability to the furniture. Additionally, steel coils can be coated or painted to enhance their appearance and protect against corrosion, making them versatile and long-lasting materials for furniture manufacturing.

- Q: I know that the steel is significantly harder than when air cooled, but why is the quenched steel harder?

- When steel is slowly cooled, lots of carbon diffusion takes place because it is not very soluble in steel at room temperature. The carbon is in solution at high temperatures, and is rejected out of the lattice as it cools. And when this happens, the microstructure will consist of ferrite and pearlite, and the lattice structure will be base centered cubic (bcc). If it is cooled fast enough, then the carbon gets trapped in the interstitial sites of the lattice and distorts it to a body centered tetragonal (same as bcc, but elongated in one direction) This elongation strains the lattice and makes it harder. Also, when cooled fast enough the atoms do not have time to diffuse like they normally would and they shear into place. This forms the hard phase of martensite that is desired of heat treated steel. But then it must be tempered back some because it is too brittle.

Send your message to us

SPCC Cr Coil/Cold Rolled Steel Coil for Building

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 m.t.

- Supply Capability:

- 50000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords