Aluminum Section Profile for Door and Window

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Aluminium is a relatively soft,durable, lightweight, ductile and malleablemetal with appearance ranging from silvery to dull gray,depending on the surface roughness. It is nonmagnetic and does not easilyignite. A fresh film of aluminium serves as a good reflector (approximately92%) of visible light and an excellent reflector (as much as98%) of medium and far infrared radiation. The yield strength of pure aluminium is 7–11 MPa,while aluminium alloys have yield strengths ranging from200 MPa to 600 MPa. Aluminium has about one-third the density and stiffnessof steel. It iseasily machined,cast, drawn and extruded.

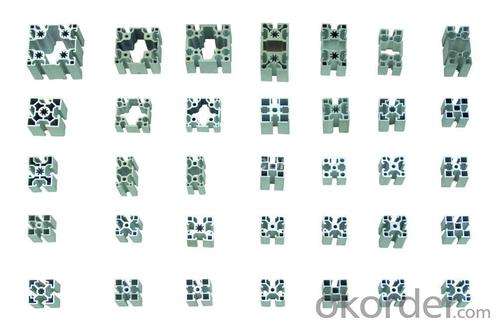

Aluminum Profile

Material | Alloy 6063,6061,6005or according to customer’s choice |

Temper | T3, T4, T5, T6 |

Surface | Anodize, electrophoresis, powder coating, PVDF coating, wood grain painting, matted, etc. |

Length | Coating 6.5 meters, Anodizing 6.5 meters, Mill finish 5 meters |

Application | Industrial, electrical equipment(TV set, air conditioner, refrigerator, computer), decoration,construction, transportation |

Custom Made | We can package following with customer's request. |

- Q: How is the aluminum alloy profile series divided?

- According to alloy composition.1 pure aluminum, such as 1100,2 series aluminum alloy3 Series al Mn alloys, such as 3003, 3A214 series Al Si alloy5 Series Al Mg alloy6 series Al Mg Si alloy, such as 606360617 Series Al Zn Alloy8 lines, others9 line standby

- Q: What is the price of aluminum paint spray?

- Powder mainly by tonnage count, usually 2-3 yuan / tonSpray painted mainly by area, usually 20-50 yuan / squareSpray paint depends on whether you want polyester or fluorocarbon, fluorocarbon expensive.

- Q: Do aluminum profiles have good thermal insulation properties?

- No, aluminum profiles do not have good thermal insulation properties.

- Q: Can aluminum profiles be used in the construction of data centers?

- Data centers can utilize aluminum profiles for construction purposes. The utilization of aluminum profiles in this industry offers numerous benefits. To begin with, aluminum possesses a combination of lightweight and sturdy properties, rendering it an excellent material for constructing structures that require the capacity to withstand heavy loads. Considering that data centers often accommodate racks of servers and other equipment, the use of aluminum profiles can provide the necessary strength without adding excessive weight. Moreover, aluminum profiles offer extensive customization options and can be easily fabricated to meet specific design requirements. This flexibility enables efficient space utilization within a data center, as the profiles can be tailored to fit the facility's layout and dimensions. Furthermore, aluminum exhibits resistance to corrosion, a crucial attribute in the data center environment where equipment produces heat and humidity levels can be high. By employing aluminum profiles, the risk of rust and corrosion is minimized, thereby ensuring the infrastructure's longevity and reliability. Additionally, aluminum is an environmentally sustainable and recyclable material, aligning with the increasing demand for eco-friendly construction practices. The utilization of aluminum profiles in data center construction contributes to reducing the facility's carbon footprint. In conclusion, due to their strength, customization capabilities, corrosion resistance, and sustainability, aluminum profiles can indeed be employed in the construction of data centers.

- Q: What are the fire safety regulations for aluminum profiles?

- The fire safety regulations for aluminum profiles vary depending on the specific application and building codes in each jurisdiction. However, in general, aluminum profiles used in construction must meet certain fire resistance standards to ensure safety. This may include factors such as the thickness and composition of the aluminum, the use of fire-resistant coatings or insulation, and compliance with international fire safety standards like ASTM E119 or EN 13501. It is important to consult local building codes and regulations to determine the specific fire safety requirements for aluminum profiles in a particular area.

- Q: This question asks for the correct procedure to install aluminum profiles.

- <p>To install aluminum profiles correctly, follow these steps: 1. Measure and mark the positions where the profiles will be installed. 2. Clean the surfaces to ensure proper adhesion. 3. Use a suitable adhesive or mechanical fasteners recommended for aluminum. 4. Align the profile with the marked positions and secure it in place. 5. Check for level and plumb, and adjust as needed. 6. Wipe away any excess adhesive and clean the profile. 7. Allow the adhesive to cure according to the manufacturer's instructions. 8. Inspect the installation for any gaps or misalignments and make corrections if necessary. Always refer to the specific installation guidelines provided by the aluminum profile manufacturer for best results.</p>

- Q: How do aluminum profiles contribute to energy-saving initiatives?

- Aluminum profiles play a significant role in promoting energy-saving initiatives for several reasons. Firstly, aluminum is a lightweight material, which means that less energy is required during transportation and installation compared to other heavy construction materials. This reduces the overall carbon footprint associated with the construction process. Additionally, aluminum profiles have excellent thermal conductivity properties. This enables them to efficiently transfer heat, which is crucial for energy-saving initiatives. By using aluminum profiles in windows, doors, and facades, buildings can benefit from improved insulation and reduced thermal bridging. This helps to maintain a comfortable indoor temperature while minimizing the need for excessive heating or cooling, thus reducing energy consumption. Moreover, aluminum profiles can be effectively combined with energy-efficient glazing systems. These systems include double or triple glazing, low-E coatings, and gas-filled cavities, which further enhance the thermal performance of windows and facades. By using aluminum profiles in conjunction with energy-efficient glazing, buildings can significantly reduce heat loss or gain, resulting in reduced energy usage for heating and cooling. Furthermore, aluminum is a highly durable and long-lasting material. Its corrosion resistance properties make it suitable for use in various weather conditions, reducing the need for frequent replacements. This durability ensures that the energy-saving benefits provided by aluminum profiles are maintained over an extended period, reducing the environmental impact associated with frequent material replacements. Lastly, aluminum is a recyclable material with a high recycling rate. The energy required to recycle aluminum is significantly lower compared to the energy needed for primary production. By promoting the use of aluminum profiles, we encourage the recycling and reuse of this material, thereby reducing the demand for new aluminum production and conserving energy resources. In conclusion, aluminum profiles contribute to energy-saving initiatives by reducing transportation and installation energy consumption, improving thermal insulation, facilitating energy-efficient glazing systems, providing durability, and promoting recycling. By incorporating aluminum profiles in construction projects, we can significantly contribute to energy conservation and sustainability efforts.

- Q: Can aluminum profiles be used in electrical switchgear manufacturing?

- Yes, aluminum profiles can be used in electrical switchgear manufacturing. Aluminum profiles are lightweight, yet strong and durable, making them an ideal choice for constructing switchgear cabinets. They offer excellent corrosion resistance, which is essential for protecting electrical components from moisture and other environmental factors. Additionally, aluminum profiles can be easily customized and fabricated to meet specific design requirements, allowing for efficient and cost-effective manufacturing processes.

- Q: Can aluminum profiles be used in agricultural applications?

- Yes, aluminum profiles can be used in agricultural applications. Aluminum is a versatile and durable material that can withstand various environmental conditions. It can be used for constructing greenhouse frames, irrigation systems, equipment supports, and other agricultural structures. Aluminum profiles offer excellent resistance to corrosion, are lightweight, and have high strength-to-weight ratio, making them suitable for use in agricultural applications.

- Q: Can aluminum profiles be used in the construction of greenhouses?

- Yes, aluminum profiles can be used in the construction of greenhouses. Aluminum is a popular choice for greenhouse framing due to its durability, lightweight nature, and resistance to corrosion. It offers structural strength while allowing for maximum light transmission, which is essential for plant growth. Additionally, aluminum profiles are easy to assemble and maintain, making them an ideal material for constructing greenhouses.

Send your message to us

Aluminum Section Profile for Door and Window

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords