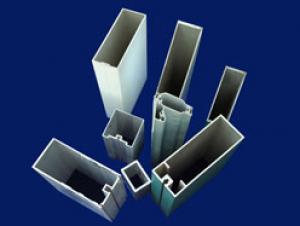

Aluminum Profiles - Anodized and Powder Coated Aluminum Profile

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Aluminium is a relatively soft, durable, lightweight, ductileand malleablemetalwith appearance ranging from silvery to dull gray, depending on the surfaceroughness. It is nonmagnetic and does not easily ignite. A fresh film ofaluminium serves as a good reflector (approximately 92%) of visible lightand an excellent reflector (as much as 98%) of medium and far infraredradiation. The yield strength of pure aluminium is 7–11 MPa,while aluminium alloys have yield strengths ranging from200 MPa to 600 MPa. Aluminium has about one-third the densityand stiffness of steel. It is easily machined,cast, drawn and extruded.

Features:

Material | Alloy 6063,6061,6005or according to customer’s choice |

Temper | T3, T4, T5, T6 |

Surface | Anodize, electrophoresis, powder coating, PVDF coating, wood grain painting, matted, etc. |

Length | Coating 6.5 meters, Anodizing 6.5 meters, Mill finish 5 meters |

Application | Industrial, electrical equipment(TV set, air conditioner, refrigerator, computer), decoration,construction, transportation |

Custom Made | We can package following with customer's request. |

- Q: Are aluminum profiles suitable for modular construction?

- Yes, aluminum profiles are highly suitable for modular construction. Aluminum is a lightweight yet strong material that offers numerous advantages for modular construction projects. Firstly, aluminum profiles have excellent structural integrity, making them suitable for supporting various loads in modular buildings. They can withstand heavy loads and provide stability, ensuring the integrity and safety of the entire structure. Secondly, aluminum profiles are corrosion-resistant, which is crucial for modular construction projects that may be exposed to different weather conditions. This resistance to corrosion enhances the durability and longevity of the modular constructions, reducing maintenance costs in the long run. Furthermore, aluminum is highly versatile and can be easily fabricated into different shapes and sizes, allowing for customized designs and adaptability in modular construction. This flexibility enables architects and engineers to create innovative and functional modular structures according to specific project requirements. In addition, aluminum profiles are lightweight compared to traditional building materials like steel, making them easier to transport and handle during the construction process. This lightness also contributes to reducing the overall weight of the modular constructions, which can be beneficial in terms of transportation costs and foundation requirements. Moreover, aluminum is a sustainable material as it is 100% recyclable, and its production process requires less energy compared to other materials. This makes it an environmentally friendly choice for modular construction projects, aligning with the growing demand for sustainable building practices. Overall, aluminum profiles offer a range of advantages that make them highly suitable for modular construction. Their strength, corrosion resistance, versatility, lightweight nature, and sustainability make them an ideal choice for creating durable, customizable, and efficient modular structures.

- Q: This question asks for an explanation of the various types of aluminum profiles that are specifically used in the construction or design of staircases.

- <p>Aluminum profiles for staircases are diverse and serve different functions. Common types include: 1. Handrail profiles, which provide support and safety. 2. Stringer profiles, forming the backbone of the staircase. 3. Tread profiles, which are the horizontal surfaces on which one steps. 4. Riser profiles, covering the vertical space between steps. 5. Baluster profiles, used as vertical supports between handrails and treads. 6. Connector profiles, for joining different parts of the staircase. Each type is designed to withstand specific loads and is chosen based on the staircase's design, weight capacity, and aesthetic requirements.</p>

- Q: This question asks for guidelines to ensure the proper and safe installation of aluminum profiles.

- <p>To ensure the correct and safe installation of aluminum profiles, follow these steps: 1. Use high-quality aluminum profiles that meet industry standards. 2. Prepare the surface by cleaning and leveling it. 3. Use appropriate tools like drills, screws, and cutting equipment. 4. Follow the manufacturer's guidelines for installation. 5. Ensure proper alignment and spacing of the profiles. 6. Secure the profiles with the right fasteners and adhesives. 7. Check for any sharp edges or protrusions after installation. 8. Regularly inspect and maintain the profiles to prevent any damage or wear. By adhering to these steps, you can ensure a safe and secure installation of aluminum profiles.</p>

- Q: Chengdu where to sell aluminum profiles of many businesses?

- This is what I learned on Baidu last year: look, maybe it will help you!Two days ago in the city to find the north gate, Xinshengda profile market have taken a little more, Sammy, the gold house electrical city only one sell Aluminum Alloy, Wanguan electrical didn't go to see, tailor steel city to ask a security guard said little or no 512, no Aluminum Alloy sold, only 512 of the next street there is a Aluminum Alloy sell (416 opposite the hospital).

- Q: Is it possible to recycle aluminum profiles through the current recycling systems in place?

- <p>Yes, aluminum profiles can be recycled using existing recycling programs. Aluminum is one of the most recycled materials globally due to its non-toxic nature and the energy efficiency of recycling it. Most recycling programs accept aluminum, and aluminum profiles can be collected, sorted, and processed to be melted down and reused in new products. It's important to check with local recycling facilities to understand their specific guidelines and requirements for recycling aluminum profiles.</p>

- Q: Where can I get it, or Jiaozhou, Jiaonan, where there are aluminium profiles? You'd better leave me a call... And do you have any training places for Thai engraving software?.

- There are three kindsThe driving current of motor and the phase speed regulation of multiphase motorUse mechanical transmission, use external transmission, internal transmissionThere are automatic transmission abroad, through the detection of the movement cycle of spokes, in the 5 battery energy, through the diameter of 2 cm small motor to change the mechanical transmission ratio.Process manufacturing process Aluminum Alloy bicycle rimYou don't lose money.Others do well, how can you grab the meal?The market is too small.Is extrusion aluminum section, to batch processing, to open the mold, China's poor performance of aluminum, can not do high-grade racing, big aircraft. The 500 thousand yuan is not enough for the first shipment.The profiles are cut off, then rolled in several rounds, protected by carbon dioxide gas.Drill spoke hole. You don't lose money.Have imported aluminum, import production lines, tens of millions of yuan bar, made in China is a special equipment, you can do it yourself, if commissioned by others to design and manufacture, absolutely compensate for death.

- Q: Is it possible to incorporate recycled aluminum extrusions into a construction project?

- <p>Yes, you can use recycled aluminum extrusions in your building project. Recycled aluminum is not only environmentally friendly but also offers the same strength and durability as new aluminum. It is commonly used in construction for framing, window and door profiles, and structural components. Ensure that the recycled aluminum meets the required industry standards for your project to guarantee quality and performance.</p>

- Q: Are aluminum profiles suitable for use in flooring systems?

- <p>Yes, aluminum profiles can be used for flooring systems. They are known for their strength, durability, and resistance to corrosion, making them ideal for various flooring applications. Aluminum profiles can be used to create modular flooring systems, providing a lightweight and easy-to-install solution. They can also be used in conjunction with other materials to create hybrid flooring systems, offering a combination of benefits such as thermal insulation, acoustic performance, and structural integrity.</p>

- Q: Are aluminum profiles weather-resistant?

- Indeed, aluminum profiles exhibit a commendable resistance to weather conditions in general. Renowned for its ability to resist corrosion and endure diverse climatic circumstances, aluminum distinguishes itself from iron or steel by not succumbing to rust. Consequently, it emerges as an exceptional material for outdoor purposes. Furthermore, aluminum profiles can undergo treatments with diverse coatings or finishes to bolster their resilience against inclement weather. These coatings offer supplementary safeguarding against detrimental UV rays, moisture, and other environmental elements. All in all, aluminum profiles prove themselves as robust and trustworthy selections for outdoor utilization, rendering them well-suited for an extensive array of industries and applications.

- Q: RT: you! What are coated aluminum profiles? What's the surface treatment? What's the difference between grain transfer and wood grain transfer? Thank you first!!!

- Aluminum Alloy profiles the most common and most primitive (referred to as aluminum), is Aluminum Alloy itself color, silver white, but this state for a long time, Aluminum Alloy surface will be oxidized into a dark gray or black. In order to solve this problem, the most common practice in our country is to spray a layer of powder (high temperature treatment) on the surface, that is electrostatic powder spraying. Also, fluorocarbon electrophoresis processing processing, wood grain transfer, the transfer grain processing fidelity is not high, in order to understand this problem quickly, the market has a film processing, high fidelity, but because the process requirements must be done in the film before powder spraying treatment, coupled with higher requirement on the film itself (the country is more before foreign or joint ventures), so the production cost is higher, in a second tier city high-grade residential.

Send your message to us

Aluminum Profiles - Anodized and Powder Coated Aluminum Profile

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords