Bosch Aluminum Extrusion Profiles for LED Light Strips

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Aluminium is a relatively soft, durable, lightweight, ductileand malleablemetalwith appearance ranging from silvery to dull gray, depending on the surfaceroughness. It is nonmagnetic and does not easily ignite. A fresh film ofaluminium serves as a good reflector (approximately 92%) of visible lightand an excellent reflector (as much as 98%) of medium and far infraredradiation. The yield strength of pure aluminium is 7–11 MPa,while aluminium alloys have yield strengths ranging from200 MPa to 600 MPa. Aluminium has about one-third the densityand stiffness of steel. It is easily machined,cast, drawn and extruded.

Aluminium alloys (or aluminum alloys; see spellingdifferences) are alloysin which aluminium(Al) is the predominant metal. The typical alloying elements are copper, magnesium,manganese,silicon,tin and zinc. There are twoprincipal classifications, namely casting alloys and wrought alloys, both of which are furthersubdivided into the categories heat-treatableand non-heat-treatable. About 85% of aluminium is used for wrought products,for example rolled plate, foils and extrusions.Cast aluminium alloys yield cost-effective products due to the low meltingpoint, although they generally have lower tensile strengthsthan wrought alloys. The most important cast aluminium alloy system is Al–Si,where the high levels of silicon (4.0–13%) contribute to give good castingcharacteristics. Aluminium alloys are widely used in engineering structures andcomponents where light weight or corrosion resistance is required

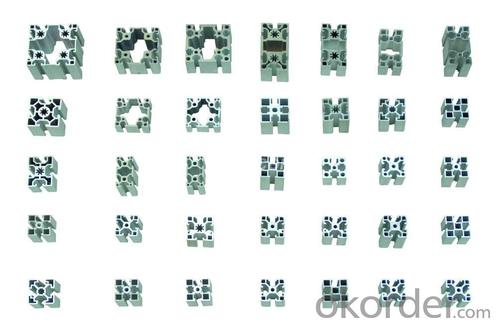

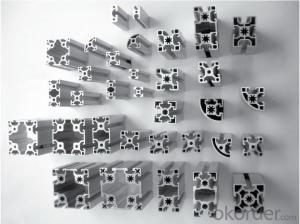

Features:

Material | Alloy 6063,6061,6005or according to customer’s choice |

Temper | T3, T4, T5, T6 |

Surface | Anodize, electrophoresis, powder coating, PVDF coating, wood grain painting, matted, etc. |

Length | Coating 6.5 meters, Anodizing 6.5 meters, Mill finish 5 meters |

Application | Industrial, electrical equipment(TV set, air conditioner, refrigerator, computer), decoration,construction, transportation |

Custom Made | We can package following with customer's request. |

FAQ:

1. What is the form of payment?

Normally 30% TT, L/C at sight

2. Type of quotation?

FOB, CFR, CIF

3. Port of loading?

Shenzhen/Guangzhou port

4. Delivery time?

15-20 days after client’s deposit

- Q: Explain how aluminum profiles contribute to the energy efficiency of a building.

- <p>Aluminum profiles significantly enhance the energy efficiency of a building through several mechanisms. They are lightweight yet strong, reducing the overall weight of the structure and the energy required for construction. Their excellent thermal conductivity allows for efficient heat transfer, which can be managed with proper insulation to reduce heat loss. Aluminum profiles also facilitate better window and door sealing, minimizing drafts and heat leakage. Additionally, their high reflectivity can help in reflecting solar heat, reducing the need for cooling. Lastly, aluminum profiles can be used in the construction of solar panels and other renewable energy systems, further contributing to a building's energy efficiency.</p>

- Q: How do aluminum profiles perform in terms of energy efficiency?

- Aluminum profiles have excellent energy efficiency performance due to their inherent properties. They are lightweight, durable, and can be easily shaped to optimize thermal insulation. Additionally, aluminum profiles can accommodate double or triple glazing, which further enhances their energy efficiency by minimizing heat transfer and reducing energy consumption for heating or cooling.

- Q: What are the different surface polishing options for aluminum profiles?

- Aluminum profiles offer various surface polishing options, each with its own shine and finish levels. These methods include mechanical polishing, chemical polishing, electrolytic polishing, and anodizing. Mechanical polishing involves using abrasives and polishing compounds to physically eliminate surface imperfections and achieve a smooth, reflective finish. This can be done manually or with automated machines. While it provides a high shine, it requires careful attention to detail and multiple steps. Chemical polishing, on the other hand, employs chemical solutions to dissolve a thin layer of aluminum, resulting in a smoother surface. It is often used for large-scale production due to its quick and uniform application, but it may not offer the same level of shine as mechanical polishing. Electrolytic polishing utilizes an electric current to eliminate surface imperfections and create a polished finish. By using the aluminum profile as an anode and a conductive material as the cathode, electrolytic polishing produces a mirror-like finish with excellent precision and uniformity. Although not a polishing method itself, anodizing is a commonly used surface treatment for aluminum profiles. It involves creating a protective oxide layer on the metal's surface through an electrochemical process. Anodizing enhances the appearance of profiles by providing a smooth, colored, or clear finish, while also improving their durability and resistance to corrosion. The choice of surface polishing option depends on factors such as the desired shine level, the complexity of the profile's design, and the intended application. It is essential to consider cost, time, and quality requirements when selecting the most suitable option, as each method has its advantages and limitations.

- Q: Is it possible to utilize aluminum profiles as a material for flooring?

- <p>Yes, aluminum profiles can be used for flooring, particularly in industrial or commercial settings where durability and resistance to wear are required. They are known for their strength, lightweight, and corrosion resistance, making them suitable for high-traffic areas. Aluminum profiles can be used to create grid systems or as support structures for modular flooring solutions. However, they are not typically used as the direct surface material for flooring due to their hardness and potential for thermal conductivity, which can make them uncomfortable underfoot. Instead, they are often part of a system that supports other flooring materials like tiles or planks.</p>

- Q: What are the various energy-saving characteristics that can be incorporated into aluminum profiles?

- <p>Aluminum profiles can incorporate several energy-saving features to enhance thermal insulation and reduce energy consumption. These include: 1. Thermal breaks: Inserts that reduce heat transfer between the interior and exterior of a profile. 2. Multi-chamber designs: Multiple air chambers within the profile that act as insulators. 3. Low-E coatings: Reflective coatings that reduce heat transfer. 4. Insulating glass units: Double or triple glazed units with gas fills that provide superior insulation. 5. Passive solar design: Profiles designed to maximize heat gain in winter and minimize it in summer. 6. High-performance seals: Gaskets and seals that minimize air infiltration. 7. Aerodynamic shapes: Profiles that reduce air resistance and heat loss. These features can significantly contribute to energy efficiency in buildings.</p>

- Q: Can aluminum profiles be used in corrosive environments?

- Aluminum profiles can be used in corrosive environments, but it is important to consider certain factors before making a decision. Aluminum is naturally resistant to corrosion due to the formation of a protective oxide layer on its surface. This layer acts as a barrier, preventing further corrosion. However, in highly corrosive environments such as areas with high humidity, saltwater exposure, or acidic conditions, the protective oxide layer may deteriorate over time. To enhance the resistance of aluminum profiles in corrosive environments, various measures can be taken. One option is to choose an aluminum alloy with higher corrosion resistance, such as aluminum alloys with a higher percentage of alloying elements like copper or zinc. These alloys are often referred to as marine-grade or corrosion-resistant alloys. Additionally, surface treatments like anodizing or powder coating can further improve the corrosion resistance of aluminum profiles. Anodizing involves the formation of a thicker and more durable oxide layer on the surface of the aluminum, while powder coating provides an additional protective layer that acts as a barrier against corrosive agents. Regular maintenance and cleaning are also crucial for preserving the corrosion resistance of aluminum profiles in corrosive environments. This includes removing any accumulated dirt or debris that may contain corrosive substances. In summary, while aluminum profiles can be used in corrosive environments, it is essential to select the appropriate alloy, consider surface treatments, and perform regular maintenance to ensure their long-term performance and durability.

- Q: What are the advantages of using aluminum profiles in the aviation industry?

- The aviation industry benefits from several advantages when utilizing aluminum profiles. To start with, the lightweight nature of aluminum is of utmost importance. In aviation, this characteristic plays a crucial role in reducing overall aircraft weight, ultimately leading to enhanced fuel efficiency. Manufacturers of aircraft can employ aluminum profiles to develop lighter structures without compromising on strength and durability. Furthermore, aluminum displays exceptional resistance to corrosion. This proves especially valuable in the aviation sector where aircraft are exposed to severe environmental conditions like high humidity, temperatures, and saltwater exposure. Aluminum profiles can withstand these conditions, effectively preventing corrosion and ensuring the long-lasting lifespan of the aircraft. In addition, aluminum profiles offer an impressive strength-to-weight ratio. This means they provide a sturdy and inflexible structure while remaining lightweight. This quality is essential for ensuring the structural integrity and safety of the aircraft. Aluminum profiles can endure the stresses and loads encountered during flight, thereby contributing to the overall safety of the aircraft. Moreover, aluminum is highly malleable, making it easy to shape and mold into intricate designs. This characteristic allows for greater design flexibility in aircraft manufacturing, enabling manufacturers to create aerodynamic and efficient structures. Aluminum profiles can be fabricated, welded, and joined with ease, providing convenience in manufacturing and assembly within the aviation industry. Lastly, aluminum is an incredibly recyclable material. With the growing emphasis on sustainability, utilizing aluminum profiles in aircraft construction helps reduce the carbon footprint. Aluminum can be recycled and reused multiple times without compromising its advantageous properties, making it an environmentally friendly choice. In conclusion, the utilization of aluminum profiles in the aviation industry offers numerous advantages, including lightweight construction, corrosion resistance, high strength-to-weight ratio, design flexibility, and recyclability. These properties position aluminum as an ideal material for aircraft manufacturing, contributing to improved fuel efficiency, safety, and sustainability.

- Q: This question asks for guidance on selecting suitable aluminum profiles for a construction project.

- <p>To choose the right aluminum profiles for your building project, consider the following: 1. Load-bearing capacity: Select profiles that can withstand the weight and stress of your structure. 2. Application: Choose profiles suitable for the specific application, such as window frames, curtain walls, or support beams. 3. Aesthetics: Opt for profiles that match your project's design and architectural style. 4. Durability: Look for high-quality aluminum with good corrosion resistance and weather resistance. 5. Cost: Compare prices and choose profiles that offer the best value for money. 6. Supplier reputation: Work with reputable suppliers known for quality products and reliable service. Consult with engineers or architects to ensure you select the most appropriate profiles for your project's needs.</p>

- Q: Can aluminum profiles be an alternative to wood in construction?

- Indeed, aluminum profiles have the potential to serve as a practical substitute for wood in the field of construction. Numerous advantages are associated with aluminum profiles, rendering them a favored choice in numerous construction projects. To begin with, aluminum profiles possess the dual qualities of being lightweight and robust, making them easily manageable and installable. This characteristic renders them suitable for a wide array of applications, including the creation of door and window frames, curtain walls, and partitions. Furthermore, aluminum profiles exhibit exceptional durability and resistance to weathering, corrosion, and pests, thereby ensuring a long-lasting and low-maintenance alternative. Moreover, aluminum profiles possess inherent fire-resistant properties, which can greatly enhance safety during the construction process. Unlike wood, aluminum does not burn, and boasts a high melting point, thereby reducing the likelihood of its contribution to the spread of fires. From an environmental standpoint, aluminum profiles offer a multitude of benefits. Aluminum is an eminently recyclable material, allowing for its repeated use and repurposing without compromising its inherent properties. This recyclability minimizes the environmental impact associated with construction projects and supports the concept of a circular economy. Furthermore, the design versatility of aluminum profiles is a distinct advantage. Aluminum can be easily shaped and extruded into various profiles and sizes, thereby enabling customization and flexibility in architectural designs. This adaptability renders aluminum profiles suitable for both functional and aesthetic purposes within the realm of construction. Nevertheless, it is vital to acknowledge that aluminum profiles may incur higher initial costs in comparison to wood. Additionally, aluminum possesses a higher thermal conductivity than wood, necessitating additional insulation to ensure optimal thermal performance. To conclude, due to their lightweight nature, durability, fire resistance, sustainability, and design versatility, aluminum profiles can serve as a viable alternative to wood in the field of construction. Though there may be certain considerations regarding cost and thermal conductivity, the numerous advantages of aluminum profiles make them an attractive option for a wide range of construction applications.

- Q: How do you calculate the strength of aluminum profiles?

- To calculate the strength of aluminum profiles, various factors need to be considered. First, the material properties of the aluminum, such as its yield strength and ultimate tensile strength, must be known. Then, the geometric characteristics of the profile, such as its cross-sectional area and moment of inertia, are used in relevant equations to determine the bending, shear, and axial strength of the profile. Additionally, factors like the loading conditions, support conditions, and safety factors are taken into account to ensure the calculated strength is reliable and safe.

Send your message to us

Bosch Aluminum Extrusion Profiles for LED Light Strips

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords