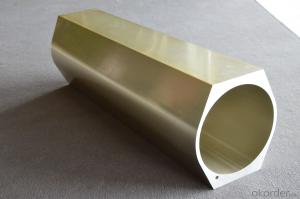

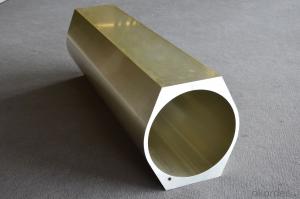

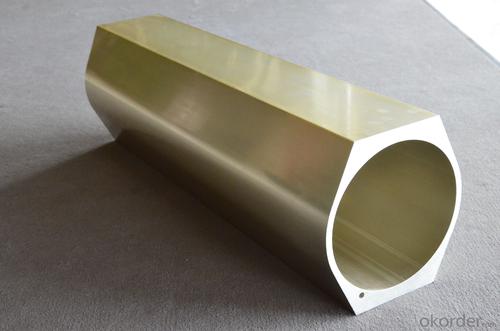

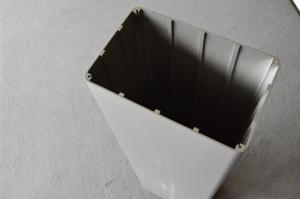

Aluminum Extrusion Channel Profiles - Aluminum Profile 005

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Aluminium Profile

1)Material : 6063 6061 6060 and different aluminium alloy

2)Status:T4 T5 T6 or other special status

3)Surface treatment: mill finish, anodized sliver ,anodized bronze, anodized champagne, anodized black pearl, various power coating color, electrostatic sliver, electrostatic champagne, electrostatic golden, electrostatic titanium , machine polish sliver, machine polish bronze, wooden grain color, and Fluorocarbon spraying.

4)Annual capacity : 120000TON

5)Quality : China Nation Standard GB/T 5237 2008 (advanced class)

6)Use: can be widely using aluminium window, door, curtain wall, hand railing , normal aluminium profile, decorative and industrial aluminium profile

7)Advantage: Famous Brand reasonable&market price, soonest delivery and good after sale- service

8)Type of package:protection foam+heat contracted plastic film. / wooden packing / Metal pallet or depand on clientspecial requirement.

9)Payment term:T/T:30% of total value as deposite should paid by T/T within 3 days when confirmation ,and the remaining sum should be paid by T/T before delivery.L/C: 100% at sight

10)Delivery Day: 15-30days

11)Honor : CHINA FAMOUS TRADEMARK, CHINA TOP BRAND, ISO9001-2000, CHINA SQUARE&ROUND COMMITTEE DNV

- Q: Are aluminum profiles suitable for use in exterior insulation systems?

- <p>Yes, aluminum profiles can be used for exterior insulation systems. They offer high strength, durability, and resistance to weathering, making them ideal for external applications. Aluminum profiles are lightweight, easy to install, and can be used to create a robust framework for insulating materials, enhancing the energy efficiency and thermal performance of buildings.</p>

- Q: Can aluminum profiles be recycled and reused for interior wall cladding purposes?

- <p>Yes, aluminum profiles can be recycled and reused in interior wall cladding applications. Aluminum is a highly recyclable material, and its recycling process does not degrade its properties, making it an excellent choice for sustainable construction. Recycled aluminum profiles can be used to create new wall cladding systems, reducing waste and the environmental impact of mining and processing new aluminum. This practice not only conserves natural resources but also contributes to energy savings and a lower carbon footprint.</p>

- Q: Can aluminum profiles be used in the production of laboratory equipment?

- Laboratory equipment manufacturing can utilize aluminum profiles effectively. Aluminum, being a versatile material, finds application in multiple industries, including the production of laboratory equipment. Aluminum profiles provide numerous benefits in this regard. To begin with, aluminum possesses a combination of lightweight and strength, making it an ideal choice for constructing portable or frequently movable equipment within laboratories. Its lightweight nature reduces the strain on laboratory personnel while handling and transporting the equipment. Moreover, aluminum profiles offer easy shaping and molding capabilities, enabling the customization of laboratory equipment to meet specific requirements. This design flexibility allows for the creation of equipment with complex shapes and structures, ensuring optimal functionality and efficiency. In addition, aluminum exhibits excellent corrosion resistance, a crucial property in laboratory settings where exposure to chemicals and liquids is common. This corrosion resistance extends the lifespan of the equipment and maintains its good condition even after prolonged use. Furthermore, aluminum profiles can be anodized or coated to provide additional protection against wear, scratches, and other forms of damage. This enhances the durability and facilitates easier cleaning, ensuring the maintenance of required hygiene standards in laboratories. Lastly, aluminum possesses high conductivity, making it suitable for applications that require heat transfer or electrical conductivity. This property proves advantageous for laboratory equipment, such as heating plates, heat sinks, or electrical circuit components. In conclusion, aluminum profiles are indeed suitable for the production of laboratory equipment. Their lightweight, malleable, corrosion-resistant, and conductive properties make them an excellent choice for manufacturing various types of laboratory equipment, guaranteeing durability, functionality, and ease of use.

- Q: Are aluminum profiles suitable for use in food processing environments?

- Yes, aluminum profiles are suitable for use in food processing environments. They are highly resistant to corrosion, lightweight, and easy to clean, making them ideal for ensuring food safety and maintaining hygienic conditions in such environments. Additionally, aluminum profiles are durable and have excellent heat and cold transfer properties, making them well-suited for various food processing applications.

- Q: This question asks for methods to protect aluminum profiles from damage during the installation process.

- <p>To prevent damage to aluminum profiles during installation, follow these guidelines: Use protective gloves and tools to avoid scratching the surface. Handle the profiles gently to prevent bending or denting. Ensure the work area is clean and free of debris that could damage the profiles. Apply protective films or tapes to vulnerable areas if necessary. Use the correct tools for cutting and drilling to avoid damaging the profile edges. Keep the profiles dry and away from corrosive substances. Always follow the manufacturer's guidelines for installation to ensure proper handling and protection of the aluminum profiles.</p>

- Q: Are aluminum profiles suitable for gym equipment?

- Yes, aluminum profiles are suitable for gym equipment. Aluminum is a lightweight and durable material that can withstand heavy use and provide excellent structural support. Its strength-to-weight ratio makes it ideal for gym equipment as it allows for easy maneuverability while still maintaining stability and durability. Additionally, aluminum is resistant to corrosion, making it suitable for environments with high humidity or moisture levels, such as gyms or fitness centers. The versatility of aluminum profiles also enables the customization of gym equipment to fit specific needs and requirements. Overall, aluminum profiles offer numerous benefits for gym equipment, making them a suitable choice for fitness facilities.

- Q: Are aluminum profiles recyclable multiple times? If yes, explain the process.

- <p>Yes, aluminum profiles can be recycled multiple times. The recycling process for aluminum involves melting the scrap aluminum, which requires only 5% of the energy needed to produce new aluminum from raw materials. After collection, aluminum profiles are sorted, cleaned, and shredded into small pieces. These pieces are then melted in a furnace and cast into new ingots or billets. From there, they can be rolled, extruded, or forged into new aluminum products. This cycle can be repeated indefinitely without loss of quality, making aluminum one of the most sustainable materials.</p>

- Q: Can aluminum profiles be used in cleanroom environments?

- Cleanroom environments can indeed utilize aluminum profiles. With its lightweight and adaptable nature, aluminum possesses a multitude of desirable qualities that make it well-suited for cleanroom applications. Being non-corrosive, non-magnetic, and boasting a high strength-to-weight ratio, aluminum is an ideal material for constructing cleanroom structures like walls, partitions, and equipment racks. Moreover, the assembly and disassembly of aluminum profiles are effortlessly accomplished, allowing for flexible cleanroom configurations and future modifications. These profiles can also be seamlessly integrated with other materials such as glass, acrylic, or stainless steel, in order to meet specific cleanroom requirements. Furthermore, aluminum profiles can be enhanced by anodization or coatings to fortify their cleanliness and resistance to contamination. Anodization furnishes a protective layer on the aluminum surface, rendering it more resistant to scratches and wear. Coatings like epoxy or powder coatings can further enhance the profiles' durability and cleanliness. In summary, aluminum profiles offer a multitude of advantages for cleanroom applications, including their lightweight nature, strength, corrosion resistance, and design flexibility.

- Q: This question asks for methods to protect aluminum profiles from corrosion and damage during the processes of transportation and storage.

- <p>To prevent corrosion and damage to aluminum profiles during transportation and storage, follow these guidelines: 1. Keep aluminum profiles dry and clean. Moisture and dirt can accelerate corrosion. 2. Use protective packaging, such as plastic wrap or padded covers, to shield profiles from physical damage and moisture. 3. Store profiles in a cool, dry place away from direct sunlight and corrosive substances. 4. Stack profiles with appropriate padding between layers to prevent scratching. 5. Avoid overloading during transportation and ensure secure fastening to prevent movement and potential damage. 6. Regularly inspect stored profiles for signs of corrosion or damage and address any issues promptly.</p>

- Q: Can aluminum profiles be used for medical equipment or devices?

- Yes, aluminum profiles can be used for medical equipment or devices. Aluminum is a widely used material in the medical industry due to its unique properties. It is lightweight, yet strong and durable, making it suitable for various medical applications. Aluminum profiles can be used to manufacture medical equipment such as hospital beds, wheelchairs, surgical tables, and diagnostic equipment. The corrosion resistance of aluminum also makes it ideal for medical devices that come in contact with bodily fluids or chemicals. Additionally, aluminum is easily sterilizable, which is crucial for maintaining a hygienic environment in healthcare settings. Overall, aluminum profiles offer numerous advantages for medical equipment and devices, making them a popular choice in the medical industry.

Send your message to us

Aluminum Extrusion Channel Profiles - Aluminum Profile 005

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords