Aluminum Print Sheets for Point-Fixing Curtain Walls

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 100000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

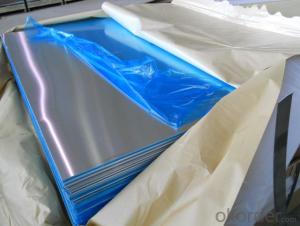

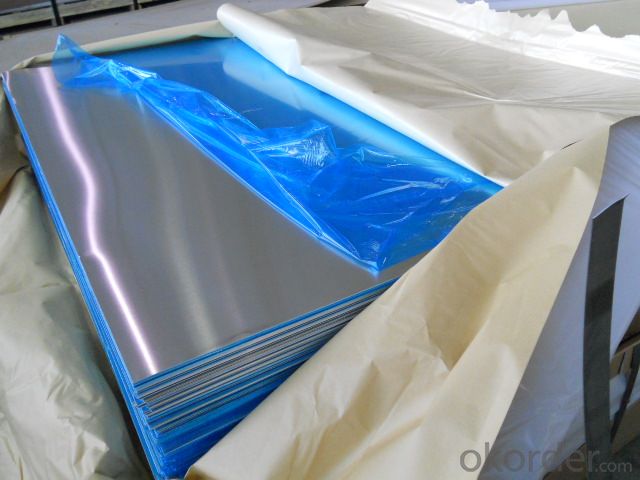

1.Structure of Aluminium Sheets for Point-fixing Curtain Walls Aluminium sheets for point-fixing curtain walls are one type of non-frame curtain wall than consist of glass panels, point-fixing components on such panels and their supporting structures. . Aluminium sheets for point-fixing curtain walls are good at ductility, heat conductivity, anti-corrosion and moisture resistance. They are widely used in roofing, electronics, instruments, lighting decoration, packing, decoration, curtain wall, sandwich panels, boats, etc. 2.Main Features of Aluminium Sheets for Point-fixing Curtain Walls •High intensity •Easy to be processed and shaped •Weather resistance •Anti-pollution & environment protection 3. Aluminium Sheets for Point-fixing Curtain Walls Images 4.Specification of Aluminium Sheets for Point-fixing Curtain Walls Alloy AA1050,AA1060, AA1070, AA1100 Temper: H12, H14, H16, H18, H22, H24, H26, H32,HO, F Thickness: 0.10-500mm Width: 10mm- 2200mm Standard: GB/T3880-2006, ASTM, ISO, EU standard Special Specification is available on customer’s requirement 5.FAQ A.What about inspections to guarantee quality? For each order for Aluminum Sheets, we will arrange strict inspection for raw materials, inspection during production and inspection for finished goods. With requirement of customers, we also can arrange the third party inspection. B.What about delivery? We will put order for Aluminum Sheets in production schedule after order gets confirmed against copy of TT or L/C. Normally it takes about one month for production. Exact shipment schedule is different based on different sizes and quantity. C.What is the MOQ? 5 tons for each size. D. What about your main markets for aluminium sheets? Main markets include South East Asia, Middle East, North America, Southc.

- Q: Can aluminum sheets be custom cut to specific dimensions?

- Yes, aluminum sheets can be custom cut to specific dimensions. Aluminum is a versatile material that can be easily cut and shaped using various tools and techniques. This allows for precise customization to meet specific requirements and dimensions. Whether it is for industrial, commercial, or residential applications, aluminum sheets can be accurately cut to desired sizes, ensuring a perfect fit and functionality. Additionally, custom cutting aluminum sheets allows for flexibility in design and enables the creation of unique and tailored solutions.

- Q: why could aluminum pot be repaired by knocking the aluminum sheet into the pot but not being bonded by glue?

- the oxidation rate of aluminum's surface is very quick, so we cann't use the method of tin welding, and the cost of argon arc welding is very high,so aluminum pot's repair usually uses riveting. aluminum has low hardness and good ductility, so it can be repaired by tightly knocking, without the bonding of glue. general glue will decomposed in open fire, if we bond pot by glue, the pot after repair won't be able to endure high temperature.

- Q: What are the different forming methods for aluminum sheets?

- The different forming methods for aluminum sheets include rolling, stamping, deep drawing, bending, and stretch forming. Rolling involves passing the aluminum sheet through a series of rollers to reduce its thickness and increase its length. Stamping uses a die to shape the sheet by applying pressure. Deep drawing involves pulling the sheet into a die cavity to create a deep and complex shape. Bending is used to create curves and angles in the sheet by applying force. Stretch forming stretches the sheet over a die to create a contoured shape.

- Q: How to polish aluminum sheet to be bright?

- as for polishing, fine grit sandpaper can't polish it into a mirror,but laser cutting can do it.

- Q: The user is asking if aluminum sheets can be used as a substitute for metal siding in construction.

- <p>Yes, aluminum sheets can be used to replace metal siding. They are lightweight, durable, and resistant to corrosion, making them a popular choice for siding. Aluminum sheets can be painted or finished to match various architectural styles and are low maintenance. However, it's important to ensure that the aluminum sheets are of the appropriate gauge and quality for the application, and that they are installed correctly to ensure longevity and performance.</p>

- Q: This question asks for a list of various types of aluminum sheets that can be used for decorative purposes.

- <p>Aluminum sheets are popular for decorative purposes due to their durability and versatility. The main types include: 1) Embossed Aluminum Sheets, which feature a textured surface for a unique look; 2) Perforated Aluminum Sheets, with holes of various sizes for a distinctive pattern; 3) Mirror Finish Aluminum Sheets, offering a reflective, shiny appearance; 4) Anodized Aluminum Sheets, which have a protective oxide layer for enhanced color and durability; 5) Brushed Aluminum Sheets, with a satin-like finish; 6) Color Coated Aluminum Sheets, available in a wide range of colors; 7) Composite Aluminum Panels, which combine aluminum with other materials for added strength and design options. Each type offers specific aesthetic and functional benefits for various decorative applications.</p>

- Q: Is it possible to use aluminum sheets for constructing car bodywork?

- <p>Yes, aluminum sheets can be used for car bodywork. They are known for their lightweight, corrosion resistance, and high strength-to-weight ratio, which makes them an ideal material for automotive applications. Aluminum is also recyclable and can contribute to the fuel efficiency of vehicles. It is commonly used in the manufacturing of car bodies, particularly in high-end and electric vehicles, for its durability and energy efficiency.</p>

- Q: Is it possible to install aluminum sheets on an existing roof structure?

- <p>Yes, aluminum sheets can be installed on existing roofs. This process typically involves removing the old roofing material and ensuring the roof structure is sound. Aluminum sheets are lightweight, durable, and resistant to corrosion, making them a popular choice for roof installations. They can be installed over a solid substrate, such as plywood or metal decking, and often require a proper underlayment to ensure watertightness. It's important to follow manufacturer guidelines and local building codes when installing aluminum sheets on an existing roof. Professional installation is recommended to ensure the roof's integrity and longevity.</p>

- Q: Are aluminum sheets suitable for decorative screens?

- Yes, aluminum sheets are suitable for decorative screens. They are lightweight, durable, and can be easily customized into various shapes and designs. Additionally, aluminum's corrosion resistance makes it suitable for both indoor and outdoor applications, making it a popular choice for decorative screens.

- Q: Can aluminum sheets be used for reflective insulation?

- Yes, aluminum sheets can be used for reflective insulation. Aluminum is highly reflective and has good thermal conductivity, making it an excellent choice for reflecting heat and reducing heat transfer. When used as insulation, aluminum sheets can reflect heat away from the surface, preventing it from entering or escaping the desired area. This can help in maintaining a comfortable temperature inside a building or protecting sensitive equipment from extreme heat or cold. Additionally, aluminum sheets are lightweight and easy to install, making them a popular choice for reflective insulation applications.

Send your message to us

Aluminum Print Sheets for Point-Fixing Curtain Walls

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 100000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords